Electromagnetic induction heating gas heat exchange experimental device

An electromagnetic induction heating and thermal experiment technology, applied in the field of energy and power, can solve the problems of poor sealing, electrification of the experimental tube, low gas density, etc., to avoid high temperature oxidation, increase the heat insulation effect, and reduce the airflow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

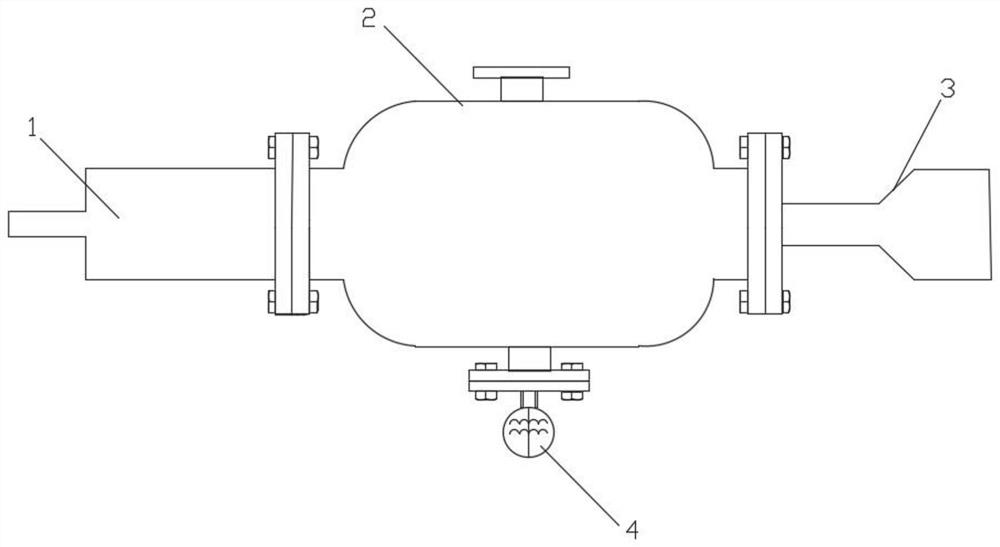

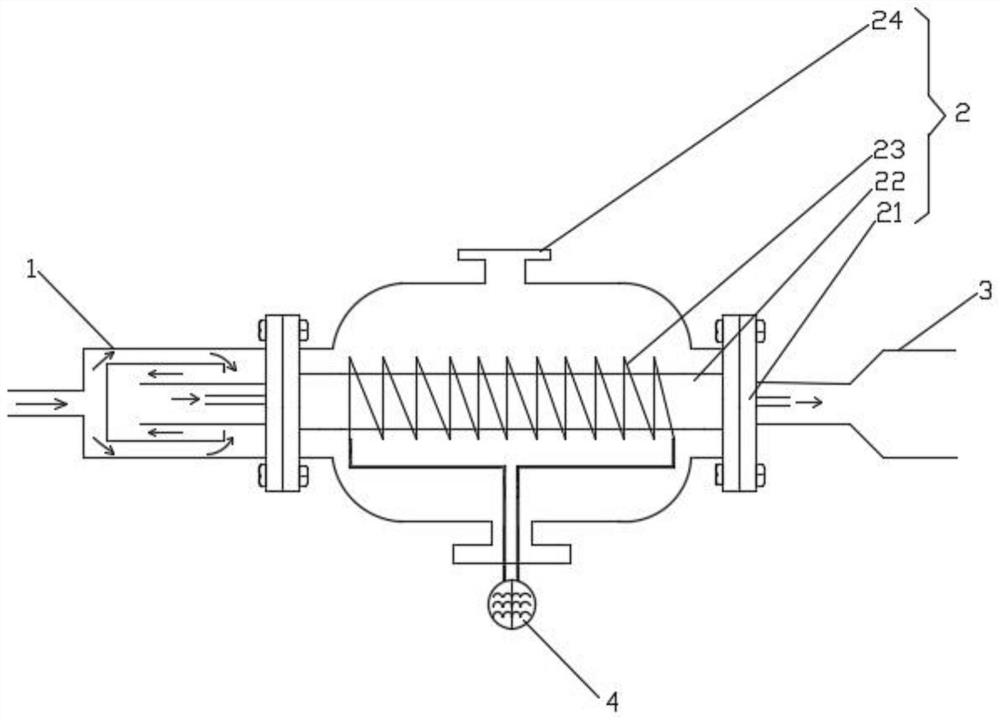

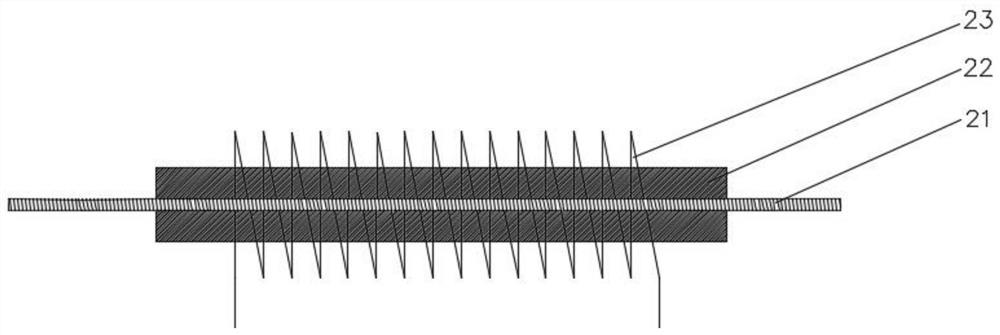

[0033] refer to Figure 1-3 An electromagnetic induction heating gas heat exchange experimental device is shown, comprising: a gas injection pipe 1; a device main body 2, the inside of which is evacuated, and the inside of the device main body 2 is provided with an experimental tube 21, a heat insulation layer 22 and an induction coil 23; One end of the pipe 21 is connected to the gas injection pipe 1; the heat insulation layer 22 is sleeved on the outside of the experimental tube 21; the induction coil 23 is sleeved on the outside of the heat insulation layer 22, and the distance between the induction coil 23 and the experimental tube 21 is 3- 25cm, and its optimum distance is 8cm; Exhaust pipe 3, the other end of exhaust pipe 3 and experiment tube 21 is connected; Induction heating power supply 4, induction heating power supply 4 is electrically connected with induction coil 23.

[0034] In this embodiment, the gas injection pipe 1 and the exhaust pipe 3 are tightly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com