Novel chromatographic column and discharging method

A chromatographic column and a new type of technology, applied in the field of chromatography, can solve the problems of inability to disperse the column bed, deformation of the filter plate, explosion safety accidents, etc., to avoid irritating odor and the danger of flammability and explosion, and reduce the operation time. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] combine Figure 1 to Figure 5 The present invention is described in further detail.

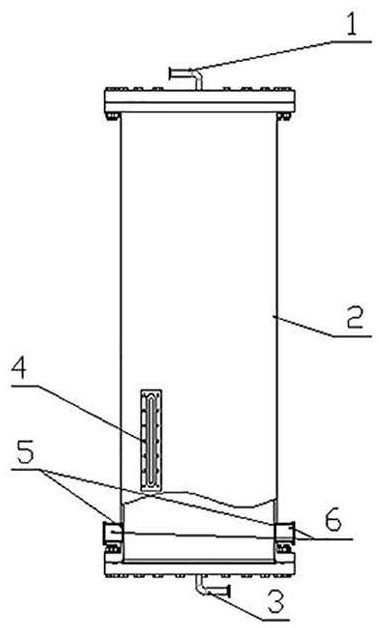

[0028] like figure 1 As shown, in the unloaded packing state, the chromatographic column includes a chromatographic column inlet 1, a column barrel 2, a chromatographic column outlet 3, a sight glass 4, a suction gun installation hole 5, and two plugs 6.

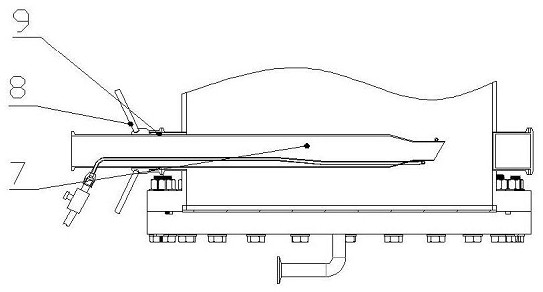

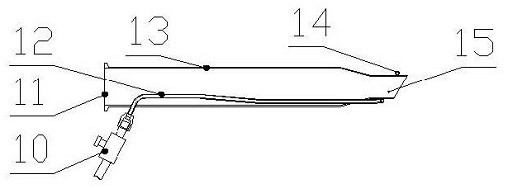

[0029] like Figure 2 to Figure 5 , in the unloading state, the figure 1 Remove the plug 6 in the middle, install the handle 8 and the sealing ring 9 on the outside of the suction gun 7, and then install it as a whole into the suction gun installation hole 5 on the left, close the throttle valve 10, and heat the gas The heater inlet 17 of the device 16 is connected with the external compressed gas, the throttle valve 10 is connected with the external compressed gas, the heater outlet 18 is connected with the chromatographic column outlet 3, and the chromatographic column inlet 1 is connected with the waste gas pipeline; The machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com