Forming device for metal parts

A molding device and metal parts technology, applied in the field of die-casting, can solve problems such as residue, unstable fluid state, poor mechanical properties of die-casting parts, etc., and achieve the effect of ensuring quality and pressure balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

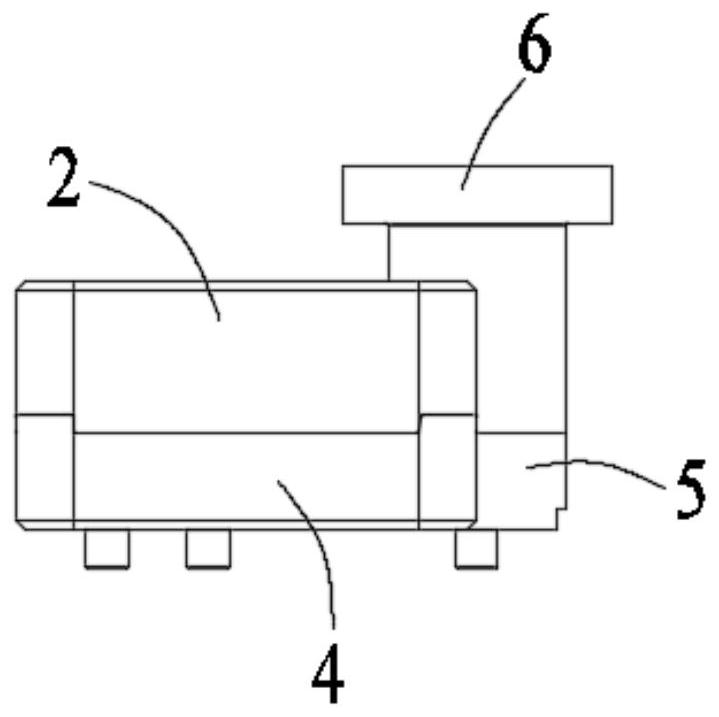

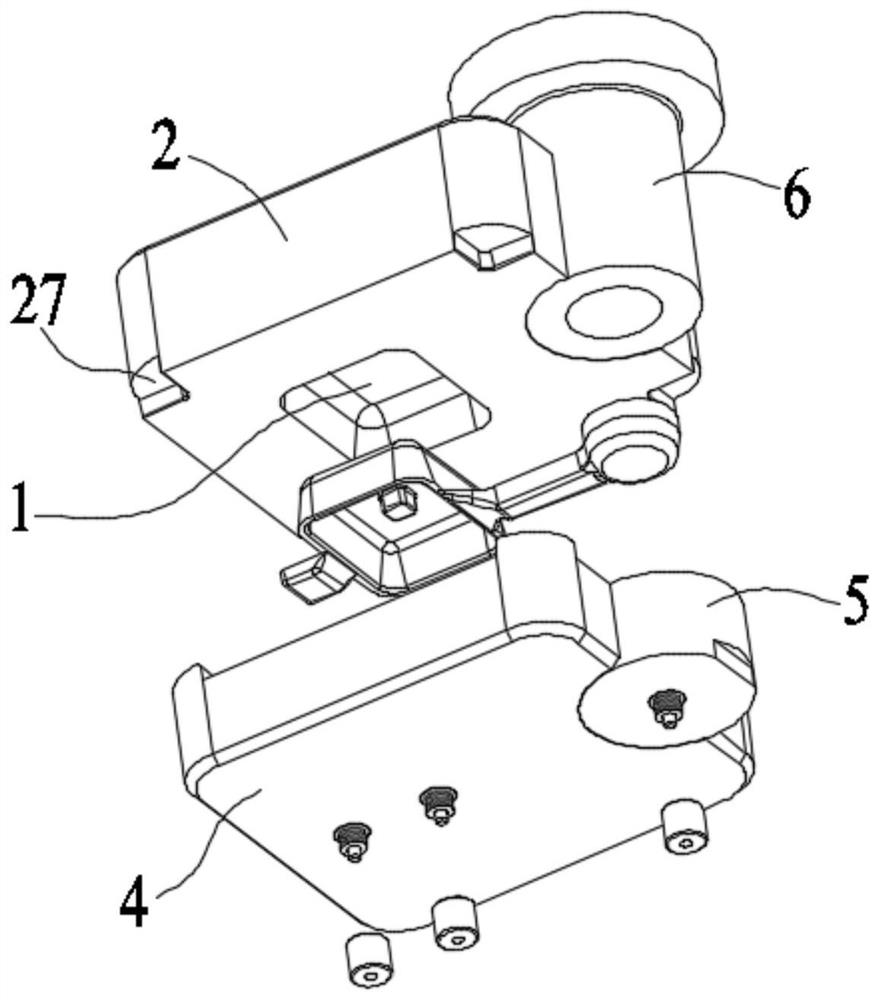

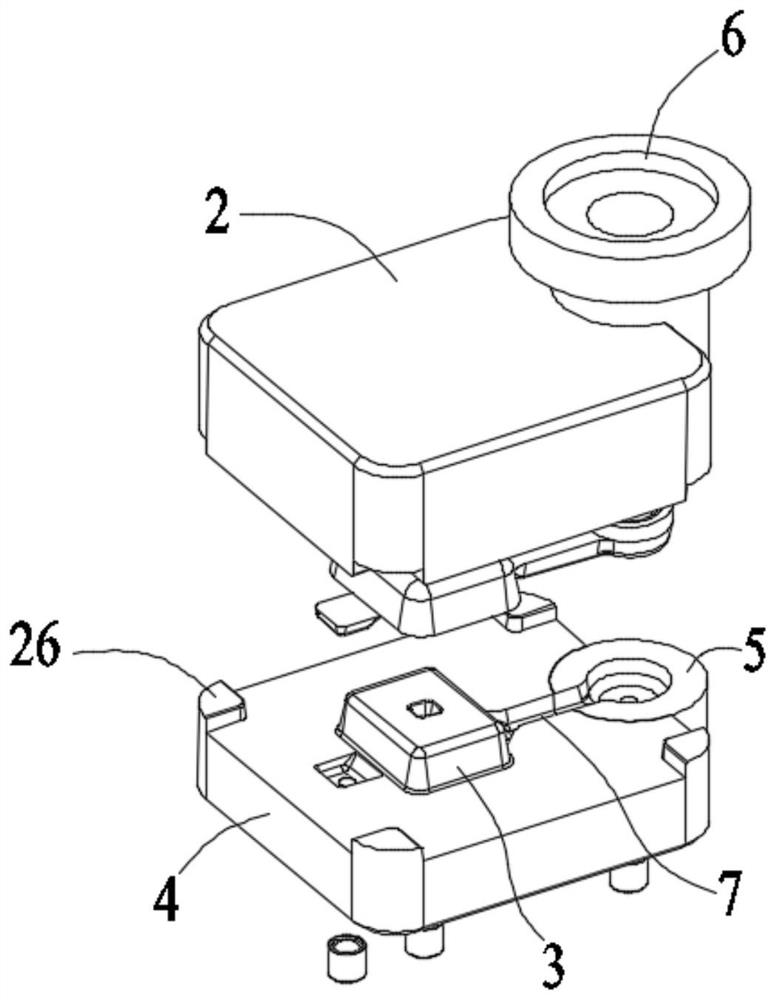

[0026] Embodiment 1: A molding device for metal parts, comprising an upper mold 2 with a cavity 1, a lower mold 4 with a core 3, a diverter cone 5 connected to one end of the lower die 4, and a diverter cone 5 connected to the diverter cone 5. Sprue sleeve 6, the upper end opening of the sprue sleeve 6 is connected to the die casting machine, the lower end of the sprue sleeve 6 is connected with the shunt cone 5 through, the upper surface of the lower mold 4 is located between the core 3 and the shunt cone 5 A first flow channel slot 7 is arranged between 5, and the first flow channel slot 7 is connected to the gap formed between the cavity 1 and the core 3;

[0027] The center of the upper surface of the core 3 has a concave portion 8, the core 3 also has a first through hole 9 penetrating through the concave portion 8, and a first through hole 9 is installed in the first through hole 9 that can be inserted into the first through hole. The first movable column 10 that moves u...

Embodiment 2

[0031] Embodiment 2: A forming device for metal parts, comprising an upper mold 2 with a cavity 1, a lower mold 4 with a core 3, a diverter cone 5 connected to one end of the lower die 4, and a diverter cone 5 connected to the diverter cone 5. Sprue sleeve 6, the upper end opening of the sprue sleeve 6 is connected to the die casting machine, the lower end of the sprue sleeve 6 is connected with the shunt cone 5 through, the upper surface of the lower mold 4 is located between the core 3 and the shunt cone 5 A first flow channel slot 7 is arranged between 5, and the first flow channel slot 7 is connected to the gap formed between the cavity 1 and the core 3;

[0032] The center of the upper surface of the core 3 has a concave portion 8, the core 3 also has a first through hole 9 penetrating through the concave portion 8, and a first through hole 9 is installed in the first through hole 9 that can be inserted into the first through hole. The first movable column 10 that moves u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com