Method for diagnosing a loaded combustion engine in terms of a leakage in a section of the fresh gas section

A fresh gas line, fresh gas technology, applied in the direction of internal combustion piston engine, combustion engine, fluid tightness test, etc., to achieve good diagnostic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

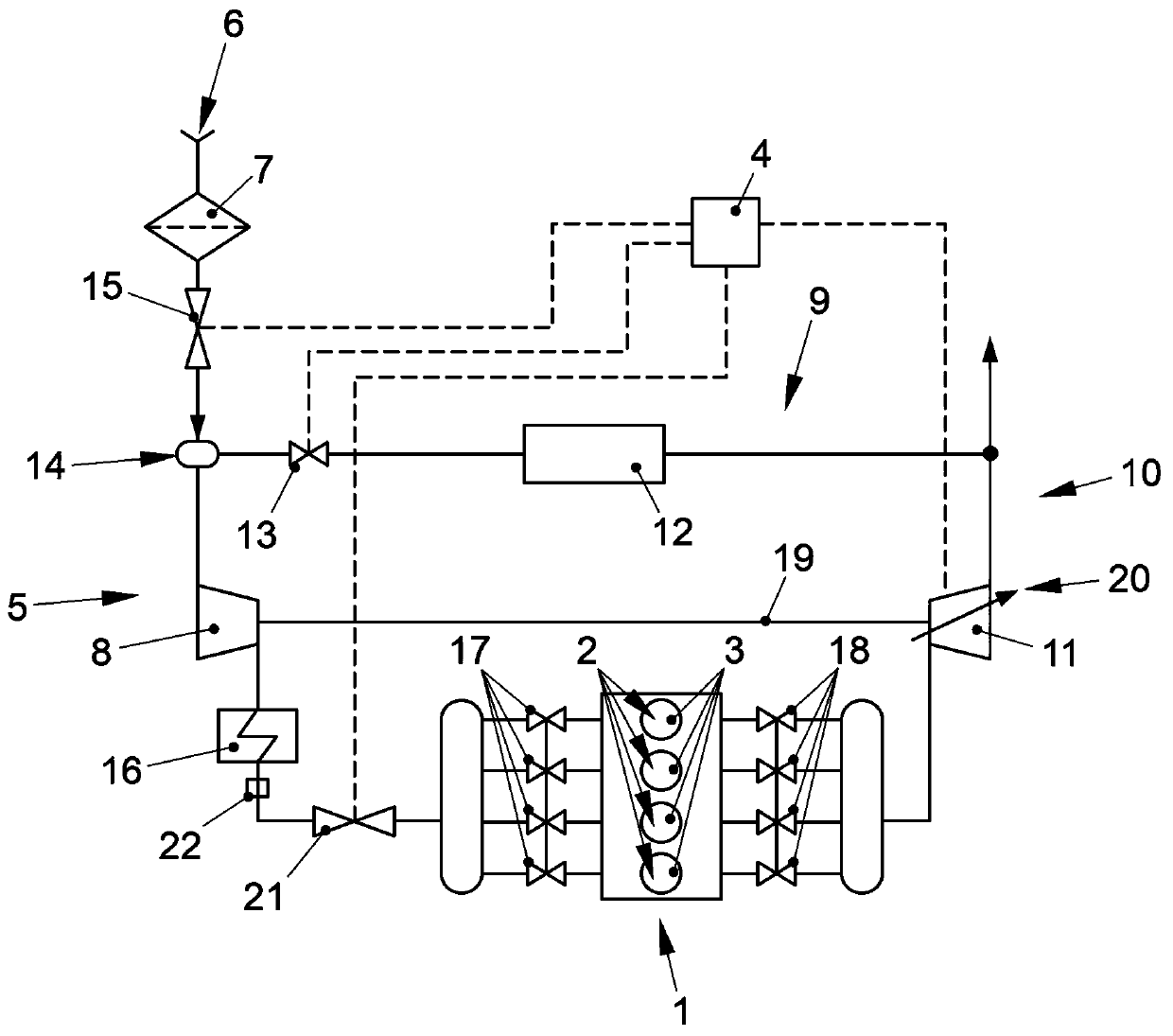

[0026] exist figure 1 The internal combustion engine shown in includes a combustion engine 1 which is constructed with a plurality of cylinders 2 . The cylinder 2 together with a piston 3 guided up and down in the cylinder 2 and a cylinder head (not shown) jointly delimit a combustion chamber in which fresh gas is combusted together with fuel. In this case, the fuel is injected directly into the combustion chamber by (not shown) injectors controlled by the control unit 4 (engine controller). Combustion of the fuel-fresh gas mixture causes piston 3 to move up and down, which in turn is transmitted in a known manner via connecting rods, not shown, to a crankshaft, also not shown, whereby the crankshaft is driven in rotation.

[0027] Fresh gas is fed into the combustion engine 1 via a fresh gas line 5 . For this purpose, air is sucked in from the environment via the intake port 6 , which is then cleaned in an air filter 7 and then fed into a fresh-gas compressor 8 which is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com