Rail transit grounding carbon brush abrasion monitoring and self-adaptive regulation and control system

A self-adaptive regulation and rail transit technology, applied in instrumentation, transportation and packaging, and measurement using digital measurement technology, can solve problems such as uneven wear of grounding carbon brushes, achieve simple and single adjustment actions, optimize car body circulation and Car body overvoltage problem, the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

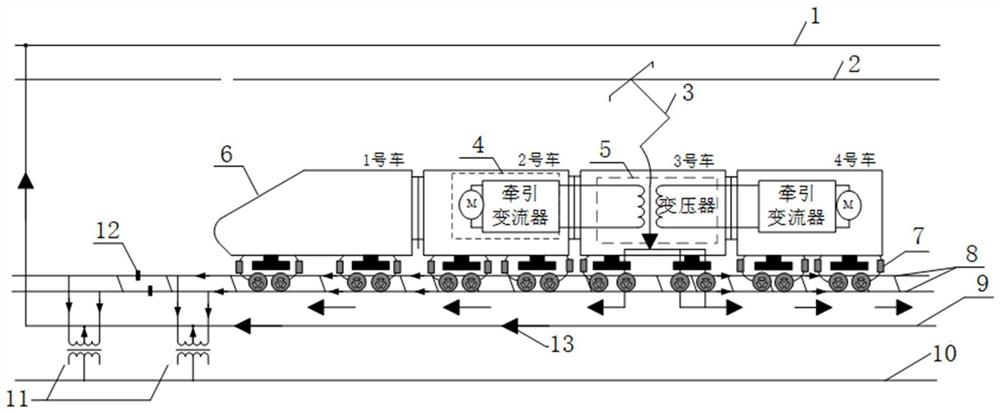

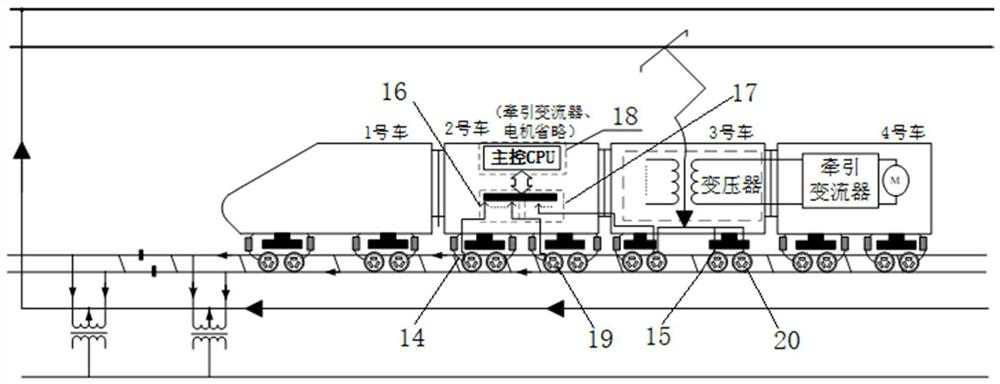

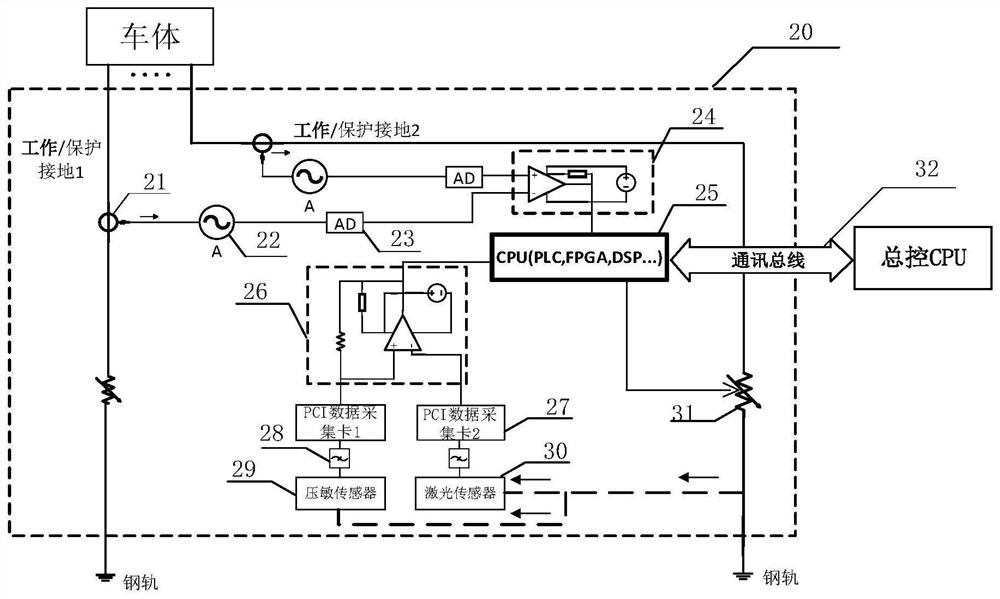

[0026] When the train is working normally, the high-speed train obtains 25KV power frequency high-voltage AC power from the catenary 2 through the pantograph 3 to drive the train. Such as figure 1 , the traction current passes through the primary side of the traction transformer 5 to provide electric energy for the traction converter and traction motor 4 driving the locomotive. Such as figure 2 , the working grounding current flows out from the traction transformer 5 and flows into the rail 8 through the sensor monitoring and control device 20 and the grounding carbon brush 19 between the grounding carbon brush 19 and the steel rail 8, and the protection grounding current is passed by the car body 6 through the grounding carbon brush 19, The sensor monitoring and control device 20 between the rails 8 and the ground carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com