Biological medicine preparation method

A technology for biomedicine and liquid injection bottle, applied in the field of biomedicine, can solve the problems of inability to realize automatic processing and production of medicines, inability to realize automatic feeding of medicine bottles, automatic filling of medicine bottles, and inability to realize continuous operation of processes, etc. To achieve the effect of reducing labor force and improving pharmaceutical production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

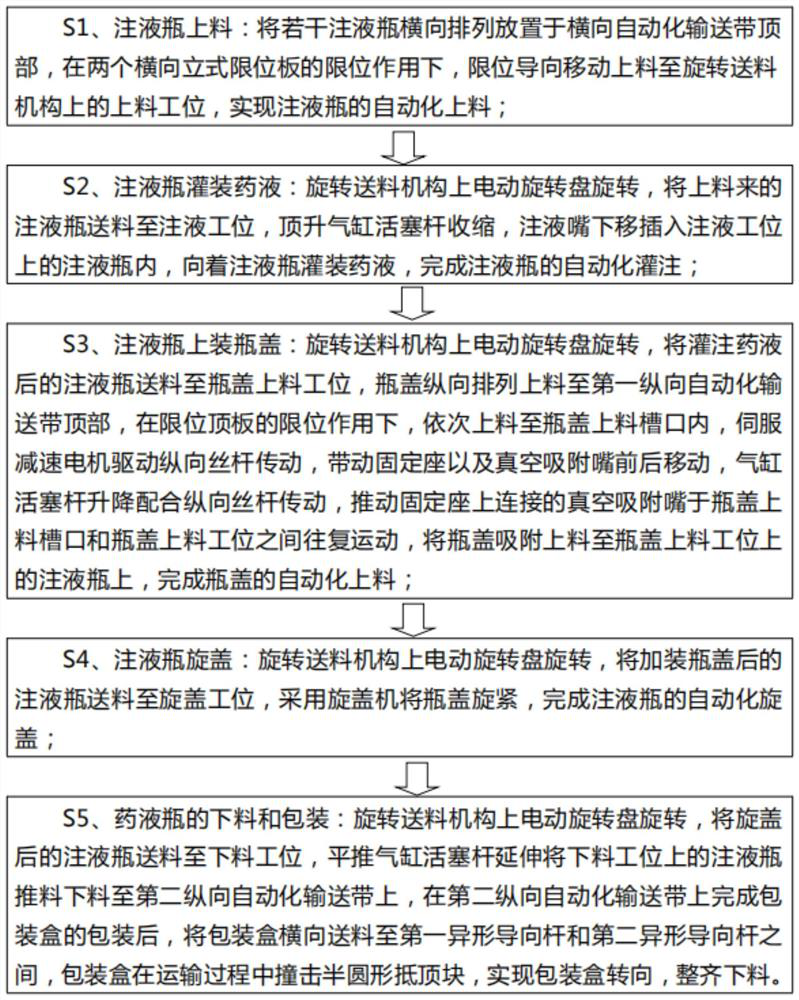

[0029] Such as figure 1 Shown, a kind of biomedicine preparation method comprises the following steps:

[0030] S1. Feeding liquid injection bottles: Place several liquid injection bottles horizontally on the top of the horizontal automatic conveyor belt. Under the limit action of two horizontal vertical limit plates, the limit guide moves and loads the material to the rotary feeding mechanism. The feeding station realizes the automatic feeding of liquid injection bottles;

[0031] S2. Filling liquid medicine in the liquid injection bottle: the electric rotary plate on the rotary feeding mechanism rotates to feed the liquid injection bottle from the loading to the liquid injection station, the piston rod of the jacking cylinder shrinks, and the liquid injection nozzle moves down and inserts into the liquid injection station. In the liquid injection bottle on the position, fill the liquid medicine into the liquid injection bottle to complete the automatic filling of the liquid...

Embodiment 1

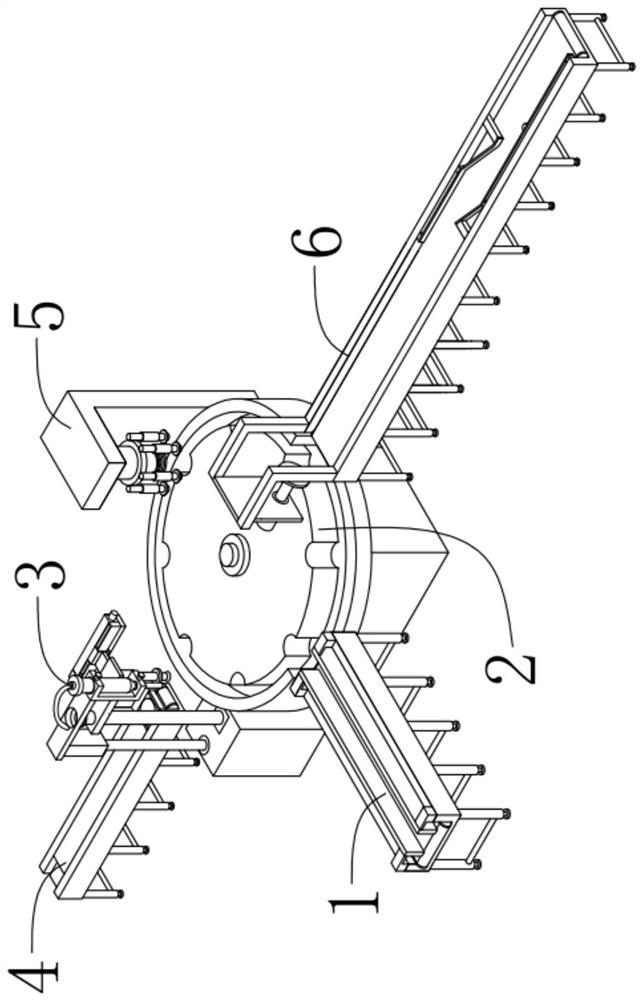

[0037] Such as figure 2 As shown, the biomedicine preparation device includes: a feeding mechanism 1, a rotary feeding mechanism 2, a liquid injection mechanism 3, a bottle cap feeding mechanism 4, a cap screwing mechanism 5, and a feeding mechanism 6;

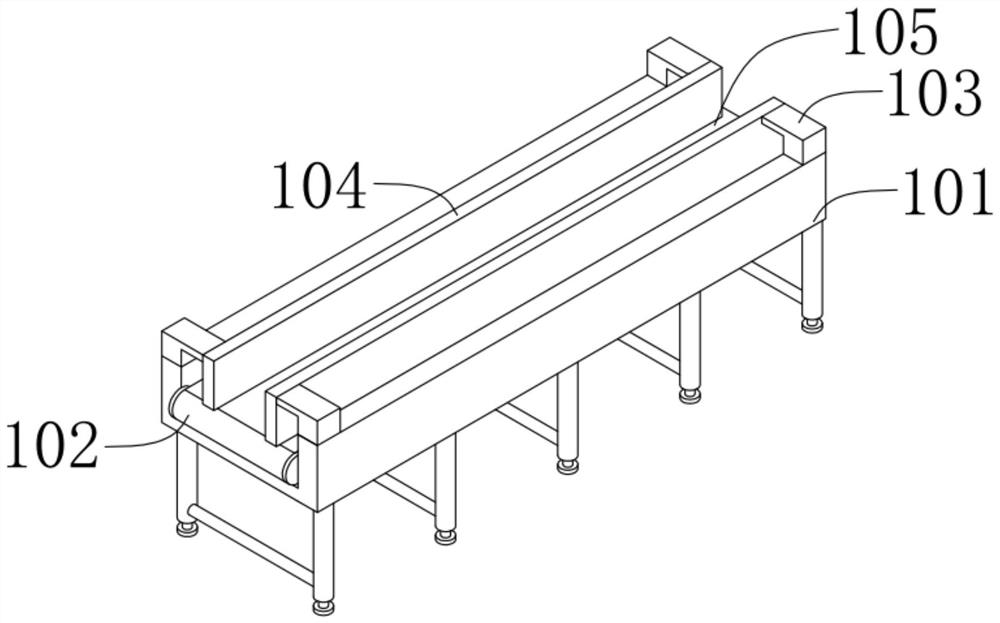

[0038] Among them, such as figure 2 with image 3 As shown, the feeding device 1 includes a horizontal conveying support 101, a horizontal automatic conveyor belt 102 arranged on the conveying support 101, four L-shaped connecting blocks 103 symmetrically arranged on the top of the horizontal conveying support 101, and symmetrically arranged front and rear. The two horizontal vertical limit plates 104 on the top of the horizontal automatic conveyor belt 102 and the limit plate that is positioned on the top of the horizontal automatic conveyor belt 102 and is located between the two horizontal vertical limit plates 104 are matched with the liquid injection bottle. Bit guide channel 105;

[0039] Among them, such as figur...

Embodiment 2

[0052] Such as figure 2 with 4 As shown, the difference between this embodiment and Embodiment 1 is that the capping machine 502 and the capping station on the rotary feeding mechanism 2 are arranged vertically symmetrically, and the discharge end of the feeding mechanism 1 is connected to the rotating The feeding station on the feeding mechanism 2 is symmetrically arranged left and right, the liquid injection nozzle 308 on the liquid injection mechanism 3 is arranged vertically symmetrically with the liquid injection station on the rotary feeding mechanism 2, and the bottle cap feeding mechanism 4 is arranged vertically symmetrically. The discharge end of the first longitudinal automatic conveyor belt 402 and the bottle cap loading station on the rotary feeding mechanism 2 are arranged symmetrically front and back. The cutting station is set symmetrically front and back.

[0053] By adopting the above technical scheme, the horizontal automatic conveyor belt 102 on the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com