Two-component polyurethane white primer and preparation method thereof

A two-component polyurethane, white primer technology, applied in the field of coatings, can solve the problems of large viscosity change, short service time, large fineness change, etc., and achieve the effect of slowing down the rising trend of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

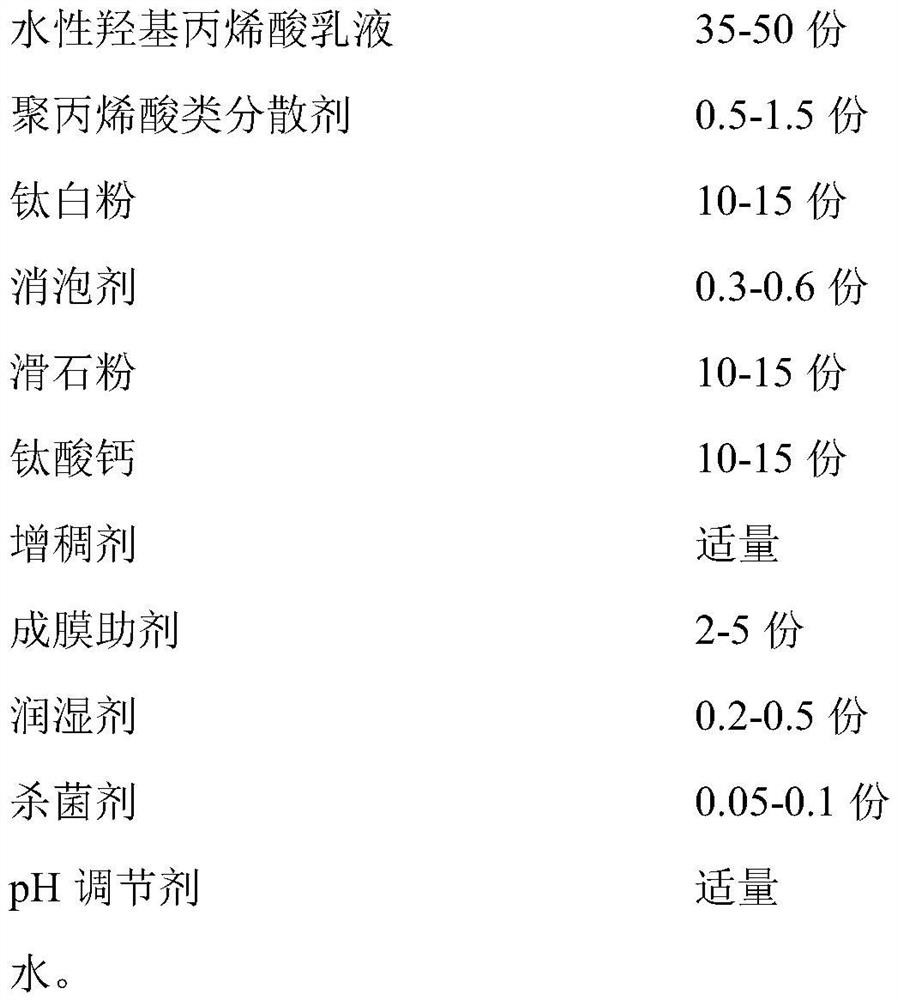

[0027] A two-component polyurethane white primer, comprising the following components in parts by mass:

[0028]

[0029] The preparation method of above-mentioned two-component polyurethane white primer comprises the steps:

[0030] S1. Add water-based hydroxyacrylic emulsion, defoamer, dispersant, titanium dioxide, calcium carbonate, talcum powder into the paint tank at a speed of 600rpm according to the above mass fraction, mix and stir, and then add film-forming aids Stir, finally add wetting agent and bactericide, and adjust the viscosity with thickener to 95s (at 25°C) with a T-4 viscosity cup, add pH regulator, stir well, and adjust to pH 7.6 , forming component A;

[0031] S2. Add the HDI isocyanate curing agent to the component A at a speed of 600 rpm according to the above mass fraction, and stir well.

Embodiment 2

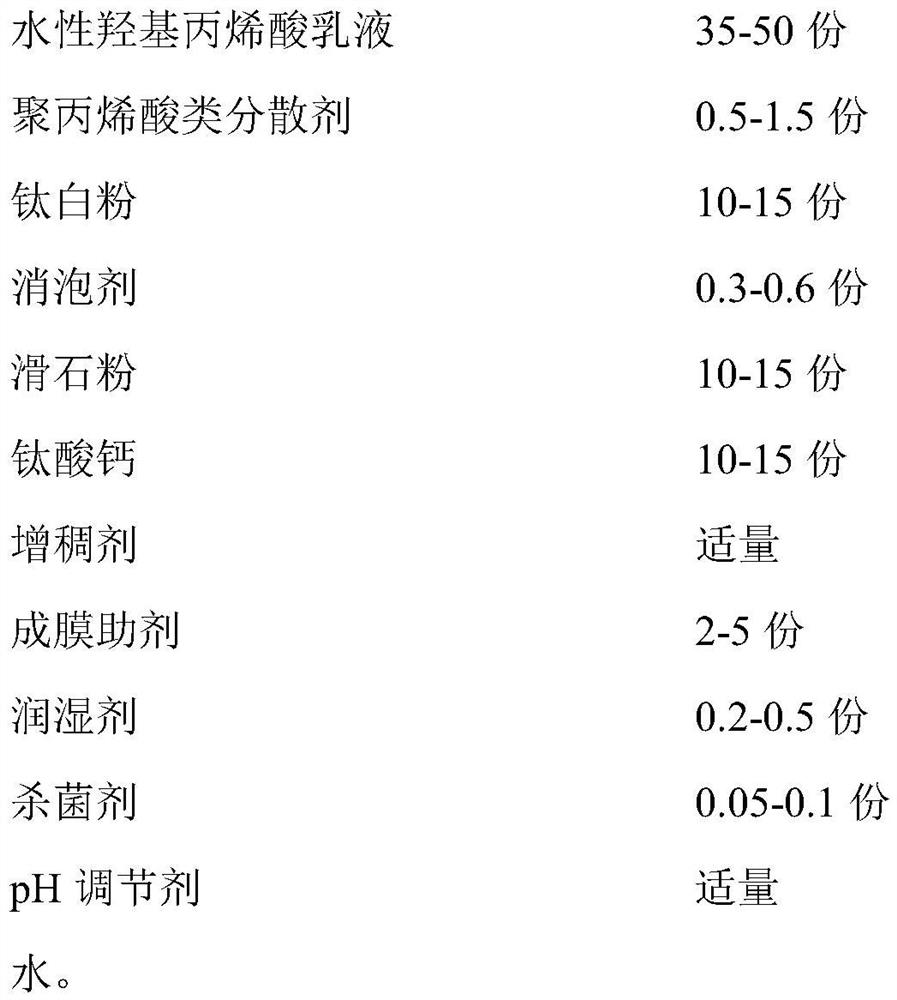

[0033] A two-component polyurethane white primer, comprising the following components in parts by mass:

[0034]

[0035] The preparation method of above-mentioned two-component polyurethane white primer comprises the steps:

[0036] S1. Add water-based hydroxyacrylic emulsion, defoamer, dispersant, titanium dioxide, calcium carbonate, talcum powder into the paint tank at the speed of 800rpm according to the above mass fraction, mix and stir, and then add film-forming aids Stir, finally add wetting agent and bactericide, and adjust the viscosity with thickener to 98s (at 25°C) with a T-4 viscosity cup, add pH regulator, stir well, and adjust to pH 7.9 , forming component A;

[0037] S2. Add the HDI isocyanate curing agent to the component A at a speed of 800 rpm according to the above mass fraction, and stir well.

Embodiment 3

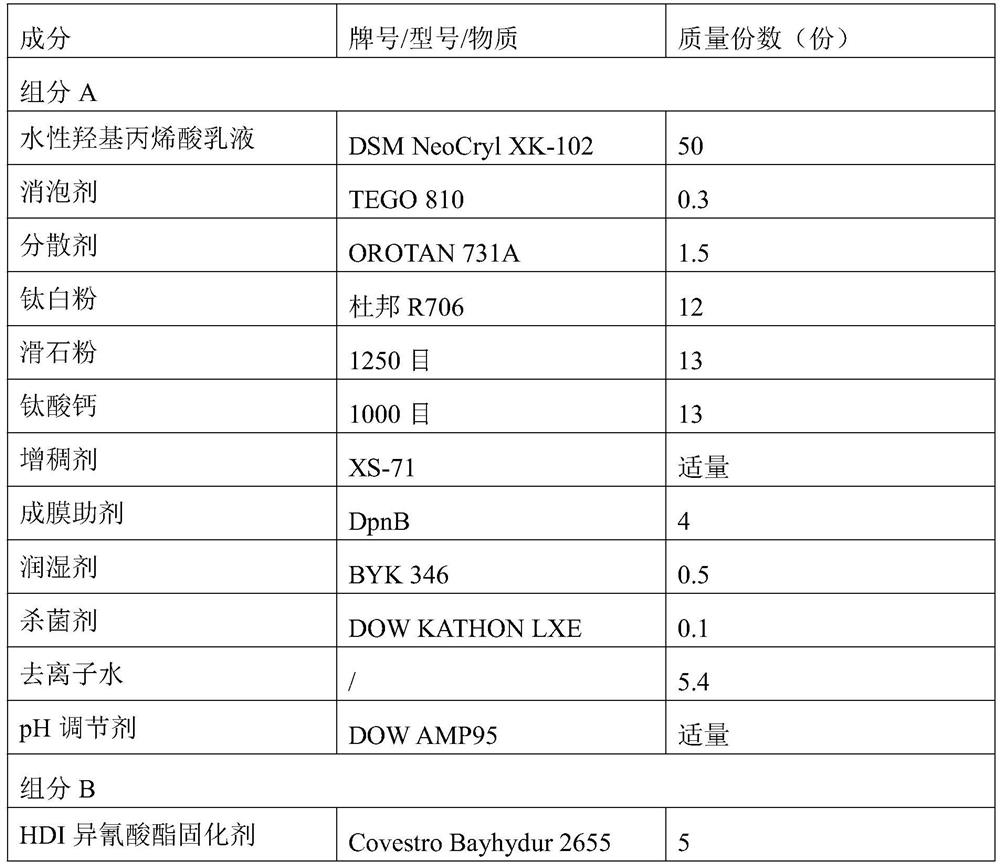

[0039] A two-component polyurethane white primer, comprising the following components in parts by mass:

[0040]

[0041] The preparation method of above-mentioned two-component polyurethane white primer comprises the steps:

[0042] S1. Add water-based hydroxyacrylic emulsion, defoamer, dispersant, titanium dioxide, calcium carbonate, talcum powder into the paint tank at the speed of 800rpm according to the above mass fraction, mix and stir, and then add film-forming aids Stir, and finally add wetting agent and bactericide, and adjust the viscosity with thickener to 97s (at 25°C) with a T-4 viscosity cup, add a pH regulator, stir well, and adjust to pH A value of 7.8 forms component A;

[0043] S2. Add the HDI isocyanate curing agent to the component A at a speed of 800 rpm according to the above mass fraction, and stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com