A co-pyrolysis method of biomass and agricultural film based on double-barreled structure

A co-pyrolysis and biomass technology, applied in the field of resource utilization of agricultural and forestry waste, can solve the problem of affecting pyrolysis efficiency and pyrolysis products, restricting the utilization of co-pyrolysis solid products, and hindering the co-pyrolysis project of biomass and agricultural film issues such as industrialization and application, to achieve the effect of promoting advancement and high industrialized production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

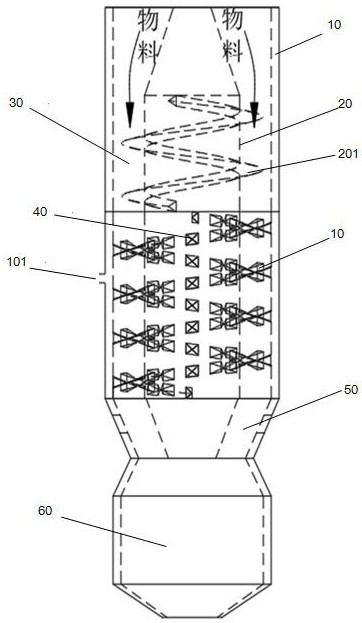

[0030] Example 1. Co-pyrolysis equipment for biomass and agricultural film based on double-barrel structure

[0031] The biomass and agricultural film co-pyrolysis equipment based on the double-barrel structure, its structure is as follows figure 1 As shown, it includes a vertically arranged outer cylinder 10 and an inner cylinder 20 vertically sleeved inside the outer cylinder. A gap 30 with a width of 50 cm for materials to pass is provided between the inner cylinder 20 and the outer cylinder 10. The inner cylinder 20 can rotate around the longitudinal axis inside the outer cylinder 10 .

[0032] The co-pyrolysis equipment as a whole includes a feed area, a co-pyrolysis area and a carbon output area from top to bottom.

[0033] In the feed zone, such as figure 1 As shown, the outer diameter of the uppermost part of the inner cylinder 20 gradually increases, forming a feed inlet with a reduced diameter with the outer cylinder 10; below the feed inlet, spiral around the inne...

Embodiment 2

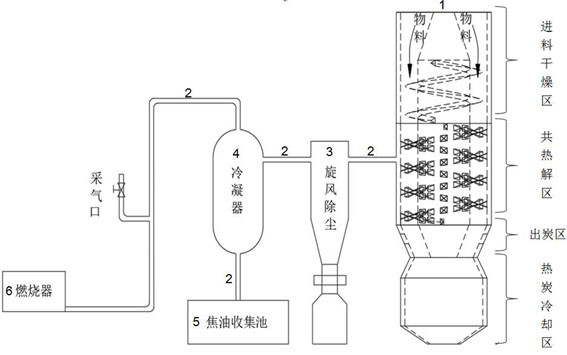

[0036] Example 2. Co-pyrolysis system of biomass and agricultural film based on double-barreled structure

[0037] The co-pyrolysis system of biomass and agricultural film based on double-barrel structure, its structure is as follows figure 2 As shown, it includes co-pyrolysis equipment 1, pipeline 2, cyclone dust removal equipment 3, oil and gas condensation equipment 4, tar collection tank 5 and burner 6 described in embodiment 1. The gas phase product outlet of the co-pyrolysis device 1 is connected to the cyclone dust removal device 3 through the pipeline 2, and the cyclone dust removal device 3 is connected to the condensation device 4 through the pipeline 2, and the bottom of the condensation device 4 passes through The pipeline 2 is connected to the tar collection pool 5, and the top is connected to the burner 6 through the pipeline 2.

Embodiment 3

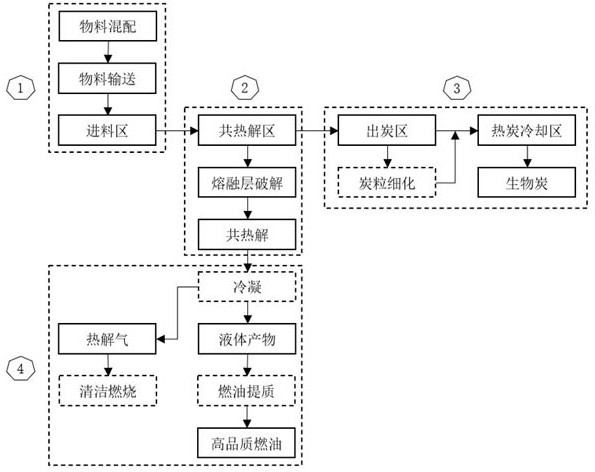

[0038] Example 3. Biomass and agricultural film co-pyrolysis process

[0039] A kind of co-pyrolysis process of biomass and agricultural film, its technological process is as follows figure 1 As shown, it mainly includes: feeding process ①, co-pyrolysis process ②, gaseous product separation process ③, and carbon discharge process ④. The process adopts the co-pyrolysis system described in Embodiment 2, wherein the co-pyrolysis equipment always controls the rotation of the inner cylinder through a frequency conversion motor during the process.

[0040] The specific steps of the process are as follows:

[0041] Process ① (feeding process): It mainly includes mixing crushed biomass from agricultural and forestry waste and agricultural film as raw materials, and then transporting the materials to the feeding area of the co-pyrolysis equipment. In the feeding area, with the rotation of the inner cylinder of the co-pyrolysis equipment, the raw materials enter the co-pyrolysis are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com