A kind of stainless steel for pump head body and preparation method thereof

A technology of stainless steel and pump head, applied in the field of metallurgy, can solve the problems of poor toughness, poor corrosion resistance, etc., achieve high strength and hardness, good comprehensive machinery, and eliminate the effect of forging stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

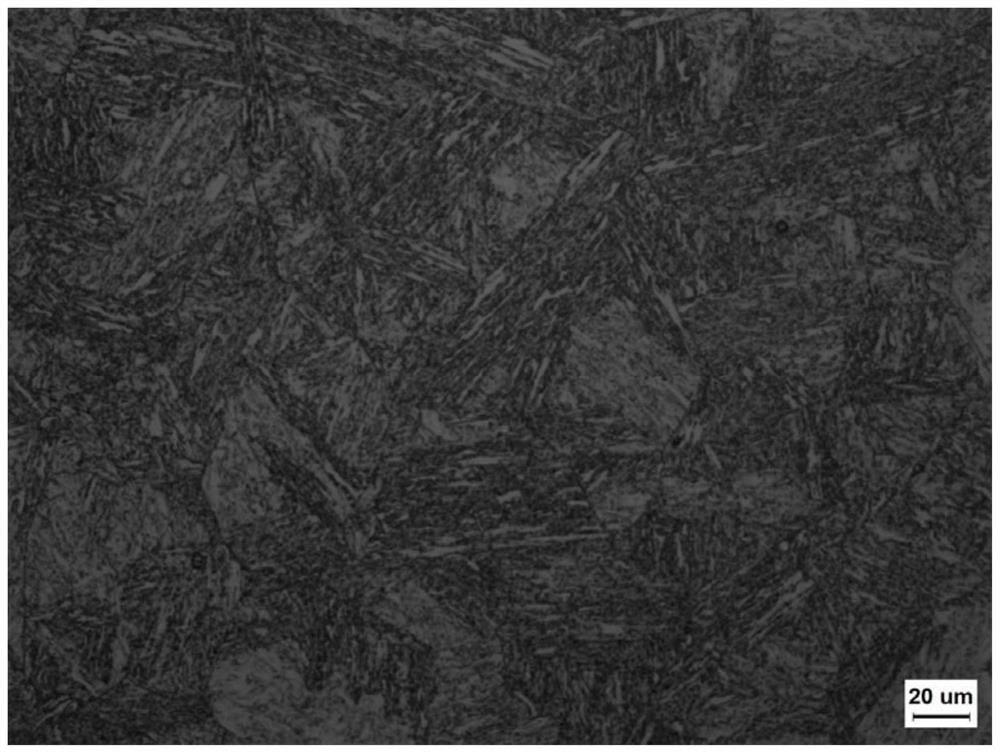

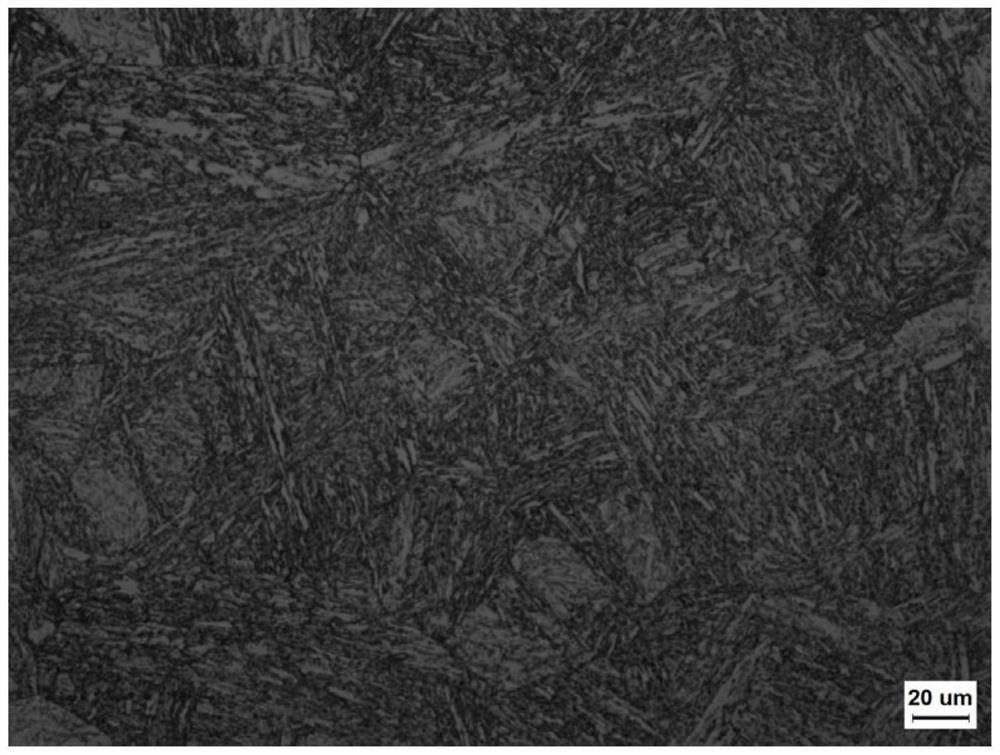

Image

Examples

Embodiment 1

[0042] This embodiment provides a stainless steel for the pump head body, which is composed of the following elements by mass percentage: C: 0.03%, Si: 0.50%, Mn: 0.95%, S: 0.008%, P: 0.010%, Cr: 14.90%, Ni: 4.50%, Mo: 1.82%, N: 0.18%, Cu: 0.36%, Ti: 0.25%, and the balance is Fe and unavoidable impurities.

[0043] Its preparation method is specifically:

[0044] (1) According to the composition and design requirements of stainless steel, the ingredients are prepared, and then smelted by a general-purpose electric arc furnace. The electric furnace smelting process is a conventional process, including: electric furnace steelmaking, refining outside the furnace, vacuum degassing, casting electroslag blanks and blank annealing, among which The annealing treatment is to keep the temperature at 1050°C for 4 hours, then cool to room temperature in the furnace, and finally obtain a mixed steel ingot;

[0045] (2) The mixed steel ingot smelted by electric arc furnace is refined by el...

Embodiment 2

[0054] This embodiment provides a stainless steel for the pump head body, which is composed of the following elements by mass percentage: C: 0.03%, Si: 0.55%, Mn: 0.90%, S: 0.008%, P: 0.010%, Cr: 15.50%, Ni: 4.60%, Mo: 1.70%, N: 0.20%, Cu: 0.31%, Ti: 0.28%, and the balance is Fe and unavoidable impurities.

[0055] Its preparation method is specifically:

[0056] (1) According to the composition and design requirements of stainless steel, the ingredients are prepared, and then smelted by a general-purpose electric arc furnace. The electric furnace smelting process is a conventional process, including: electric furnace steelmaking, refining outside the furnace, vacuum degassing, casting electroslag blanks and blank annealing, among which The annealing treatment is to keep warm at 1080°C for 5 hours and then cool to room temperature in the furnace, and finally obtain a mixed steel ingot;

[0057] (2) The mixed steel ingot smelted by electric arc furnace is refined by electrosla...

Embodiment 3

[0066] This embodiment provides a stainless steel for the pump head body, which is composed of the following elements by mass percentage: C: 0.02%, Si: 0.48%, Mn: 0.98%, S: 0.008%, P: 0.009%, Cr: 15.00%, Ni: 4.80%, Mo: 1.72%, N: 0.20%, Cu: 0.39%, Ti: 0.23%, and the balance is Fe and unavoidable impurities.

[0067] Its preparation method is specifically:

[0068] (1) According to the composition and design requirements of stainless steel, the ingredients are prepared, and then smelted by a general-purpose electric arc furnace. The electric furnace smelting process is a conventional process, including: electric furnace steelmaking, refining outside the furnace, vacuum degassing, casting electroslag blanks and blank annealing, among which The annealing treatment is to keep the temperature at 1060°C for 4 hours, then cool to room temperature in the furnace, and finally obtain a mixed steel ingot;

[0069] (2) The mixed steel ingot smelted by electric arc furnace is refined by el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com