Environment-friendly high-elasticity antistatic fabric and production technology thereof

An antistatic and fabric technology, which is applied in the processing of textile materials, weaving, vibration treatment, etc., can solve the problems of single function and cannot meet the multifunctional requirements of fabrics, etc., and achieve increased specific surface area, high recovery, and convenient adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

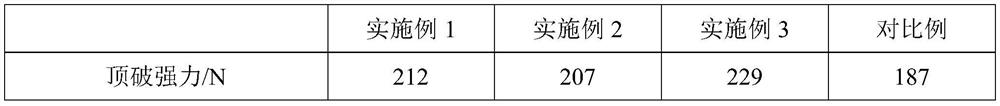

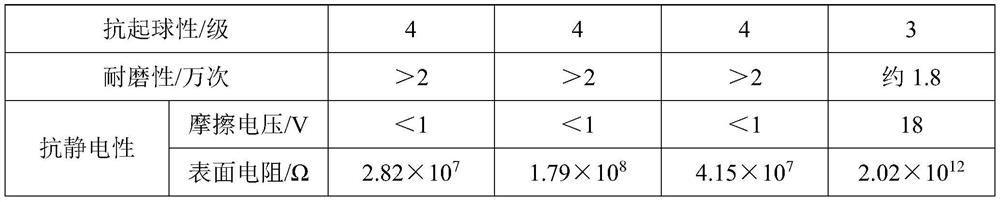

Embodiment 1

[0045] An environmentally friendly high-elastic antistatic fabric, which is woven from modified polylactic acid fiber, modal fiber and spandex fiber after processing into yarn; the mass ratio of modified polylactic acid fiber, modal fiber and spandex fiber is 1:0.4:0.08 ;

[0046] Wherein, the preparation method of modified polylactic acid fiber is:

[0047] Step 1, after removing impurities and cleaning the polylactic acid fiber, obtaining a polylactic acid fiber treated product;

[0048] Step 2, surface-treating the treated polylactic acid fiber with trimellitic anhydride to obtain a surface-treated polylactic acid fiber;

[0049] Step 3, placing nano-molybdenum diselenide in lye for treatment to obtain a molybdenum diselenide treated product;

[0050] Step 4, reacting the polylactic acid fiber surface treatment with the molybdenum diselenide treatment to obtain molybdenum diselenide / polylactic acid fiber;

[0051] In step 5, the molybdenum diselenide / polylactic acid fibe...

Embodiment 2

[0074] An environmentally friendly high-elastic antistatic fabric, which is spun from modified polylactic acid fiber, modal fiber and spandex fiber after being processed into yarn; the mass ratio of modified polylactic acid fiber, modal fiber and spandex fiber is 1:0.2:0.05 ;

[0075] Wherein, the preparation method of modified polylactic acid fiber is:

[0076] Step 1, after removing impurities and cleaning the polylactic acid fiber, obtaining a polylactic acid fiber treated product;

[0077] Step 2, surface-treating the treated polylactic acid fiber with trimellitic anhydride to obtain a surface-treated polylactic acid fiber;

[0078] Step 3, placing nano-molybdenum diselenide in lye for treatment to obtain a molybdenum diselenide treated product;

[0079] Step 4, reacting the polylactic acid fiber surface treatment with the molybdenum diselenide treatment to obtain molybdenum diselenide / polylactic acid fiber;

[0080] In step 5, the molybdenum diselenide / polylactic acid ...

Embodiment 3

[0103] An environmentally friendly high-elastic antistatic fabric, which is spun from modified polylactic acid fiber, modal fiber and spandex fiber after being processed into yarn; the mass ratio of modified polylactic acid fiber, modal fiber and spandex fiber is 1:0.2~0.6 :0.05~0.1;

[0104] Wherein, the preparation method of modified polylactic acid fiber is:

[0105] Step 1, after removing impurities and cleaning the polylactic acid fiber, obtaining a polylactic acid fiber treated product;

[0106] Step 2, surface-treating the treated polylactic acid fiber with trimellitic anhydride to obtain a surface-treated polylactic acid fiber;

[0107] Step 3, placing nano-molybdenum diselenide in lye for treatment to obtain a molybdenum diselenide treated product;

[0108] Step 4, reacting the polylactic acid fiber surface treatment with the molybdenum diselenide treatment to obtain molybdenum diselenide / polylactic acid fiber;

[0109] In step 5, the molybdenum diselenide / polylact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com