Multilayer sleeve type superconducting magnet and manufacturing method thereof

A technology of superconducting magnets and multi-layer bushings, which is applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc. It can solve problems such as power loss and increase cooling costs, and achieve stable output and high magnetic field The effect of gradient and strong magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

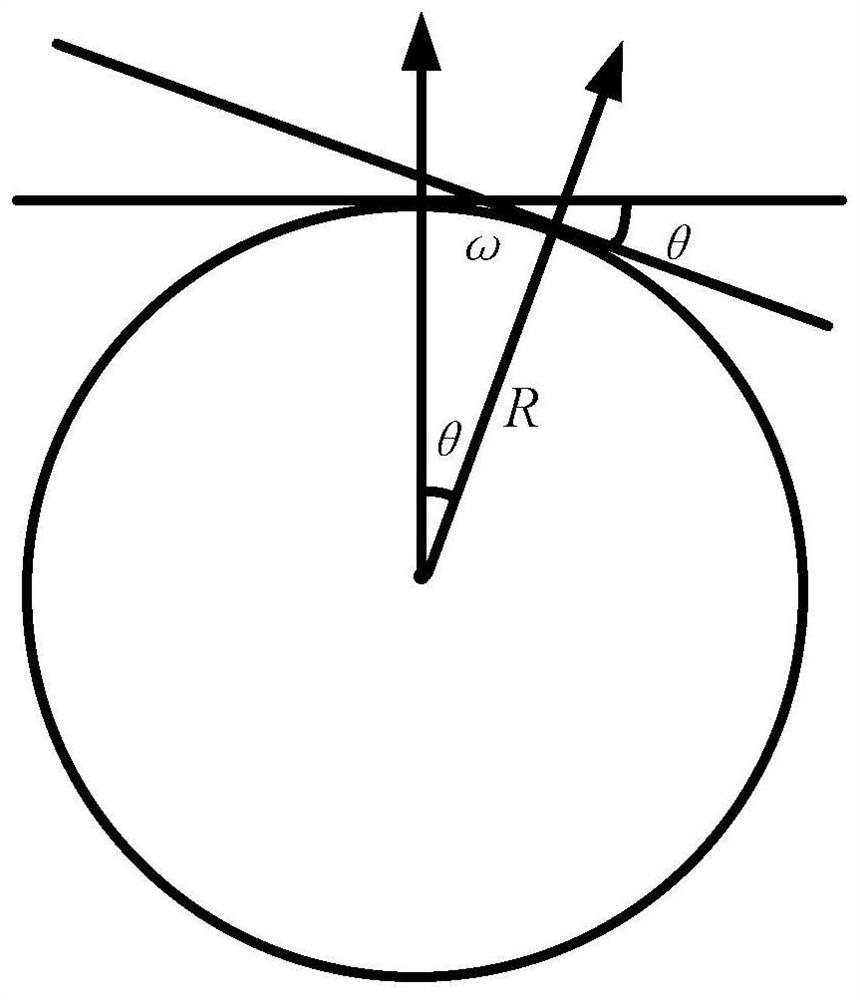

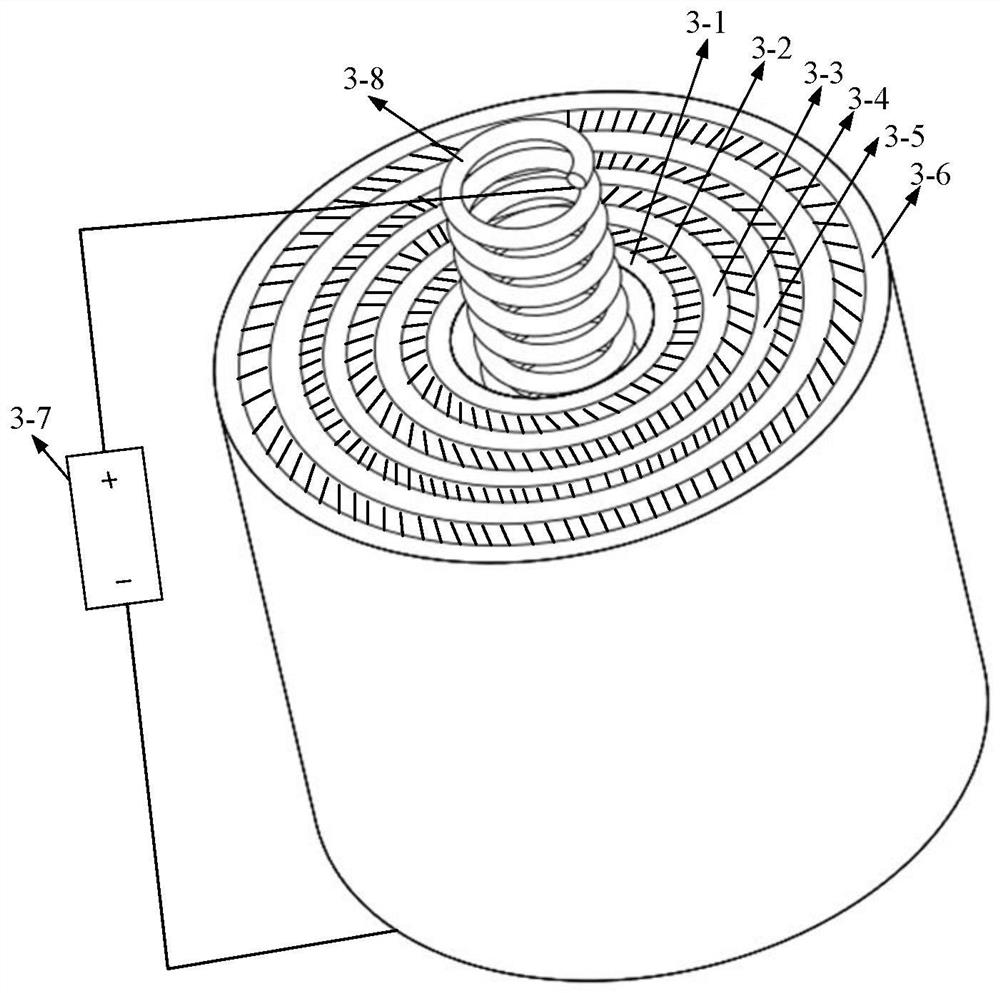

[0016] The invention provides a multi-layer casing type high-temperature superconducting magnet and its manufacturing method. The multi-layer casing type superconducting magnet is composed of a plurality of cylindrical superconducting sheets with the same height and small to large radii set one by one. There is a layer of insulating sheet between every two cylindrical superconducting sheets for insulation. A double-layer coil of copper wire is placed in the center of the superconducting sheet with the smallest radius, and the external pulse power supply uses the principle of a magnetic flux pump to supply power to it. The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

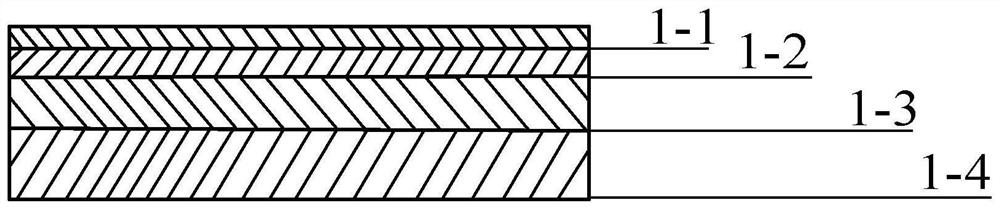

[0017] figure 1 Shown is a schematic structural view of the REBCO superconducting sheet; the superconducting sheet is composed of a substrate 1-4, a buffer layer 1-3, a REBCO thin film 1-2 and a protective layer 1-1 arranged in sequence from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com