High-voltage rapid silicon carbide diode and production method thereof

A technology for silicon carbide diodes and production methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low voltage, slow conduction speed, and small Schottky barrier area of silicon carbide diodes, and achieve conduction speed. Fast, large voltage, large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

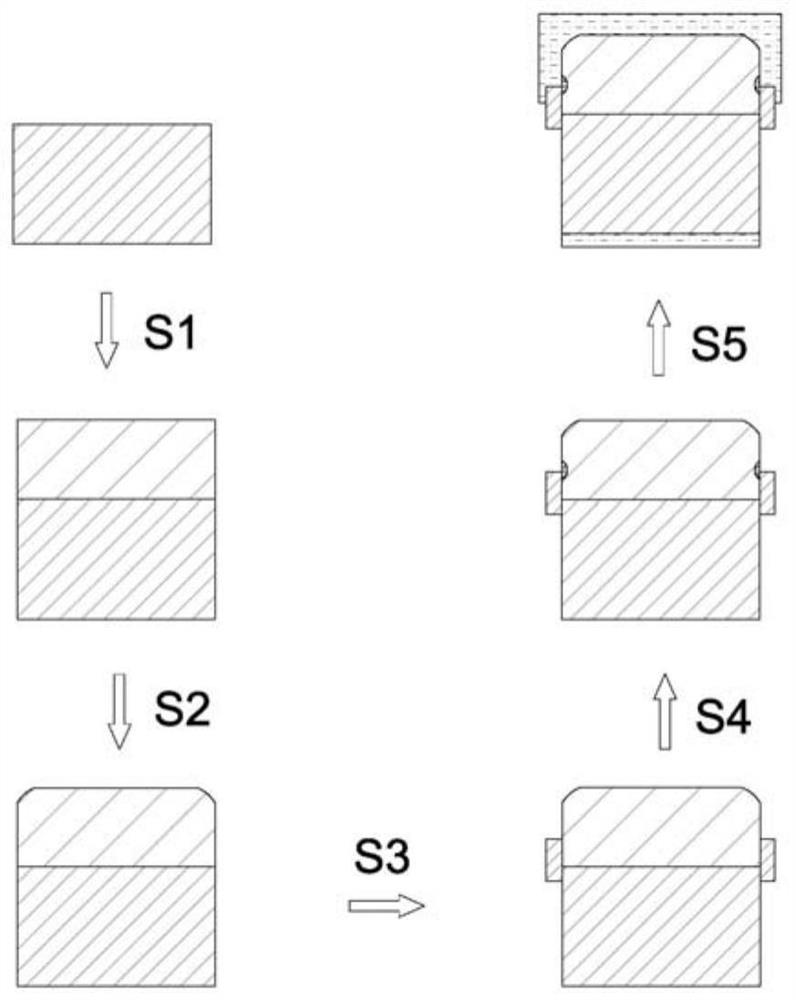

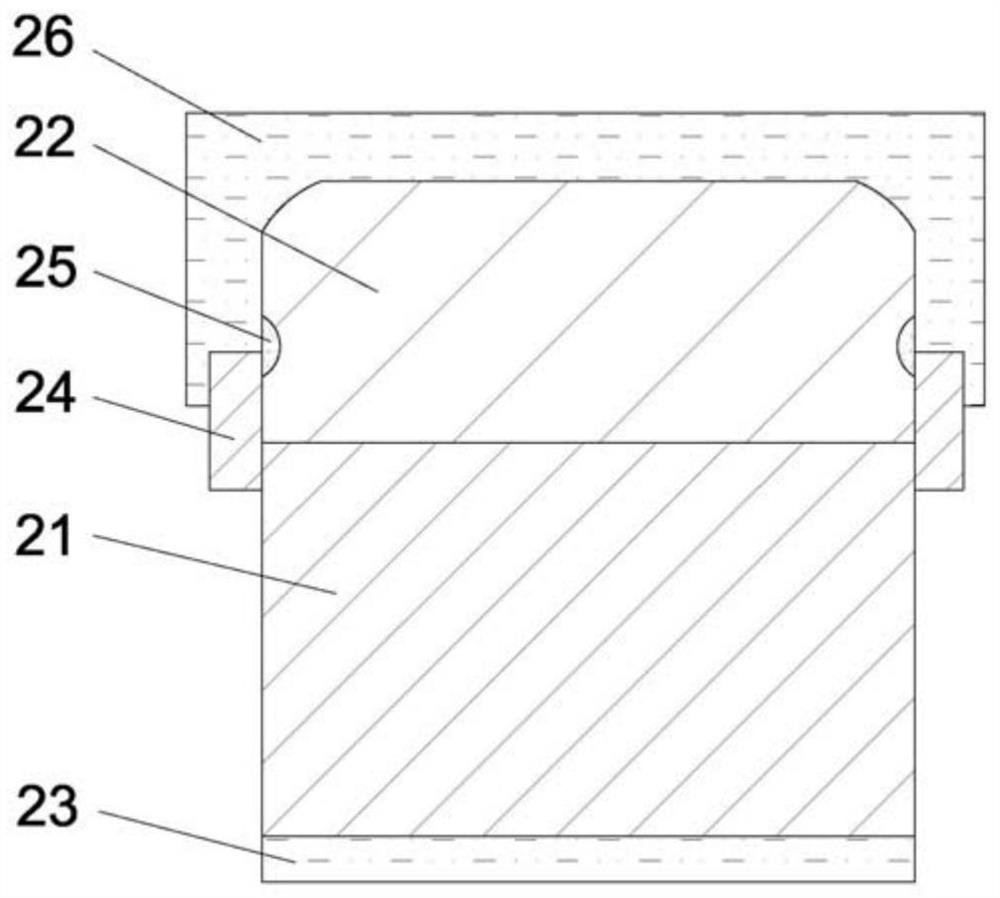

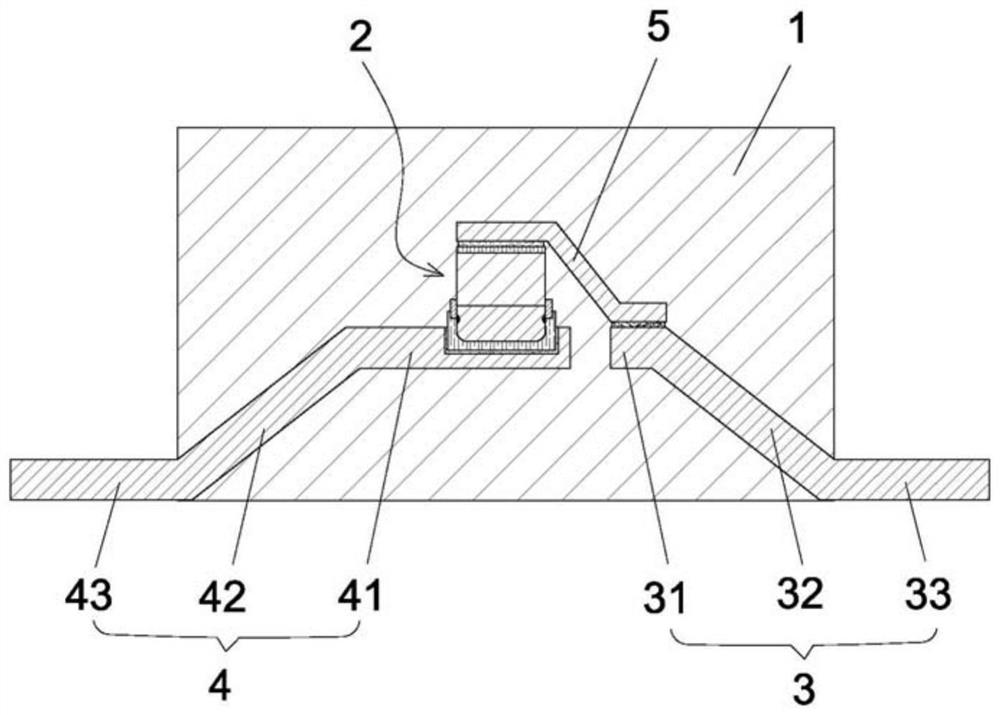

[0029] Such as Figure 1-3 Shown:

[0030] A high-voltage and fast silicon carbide diode, including a silicon carbide diode, the silicon carbide diode includes a plastic package 1, a silicon carbide chip 2, a cathode pin 3, an anode pin 4, and a welding aid 5, and the silicon carbide chip 2 includes N + SiC substrate 21, covered in N + N on the upper end of the silicon carbide substrate 21 - SiC epitaxial layer 22, covered in N + The cathode metal 23 at the lower end of the silicon carbide substrate 21 is located at N + SiC substrate 21 with N - The silicon dioxide layer 24 on the outer side of the junction of the silicon carbide epitaxial layer 22 is located at N + SiC substrate 21 with N - The P-type guard ring 25 inside the junction of the silicon carbide epitaxial layer 22 covers the silicon dioxide layer 24, N - The anode metal 26 on the upper end of the silicon carbide epitaxial layer 22, the anode metal 26 is welded to the anode pin 4, one end of the welding aid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com