Air floating type efficient coating equipment for photovoltaic panel

A coating equipment and air-floating technology, applied in the field of air-floating high-efficiency coating equipment, can solve the problems of difficulty in ensuring the surface cleanliness of the photovoltaic panel coating, reducing the economic benefits of the photovoltaic panel coating, affecting the quality of the photovoltaic panel coating, etc. The effect of input cost, reduced working environment requirements, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

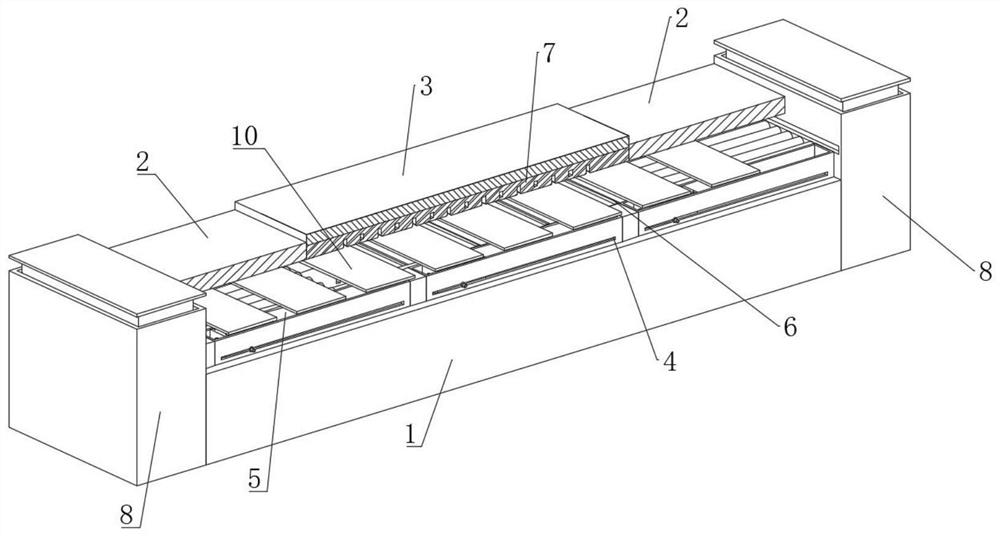

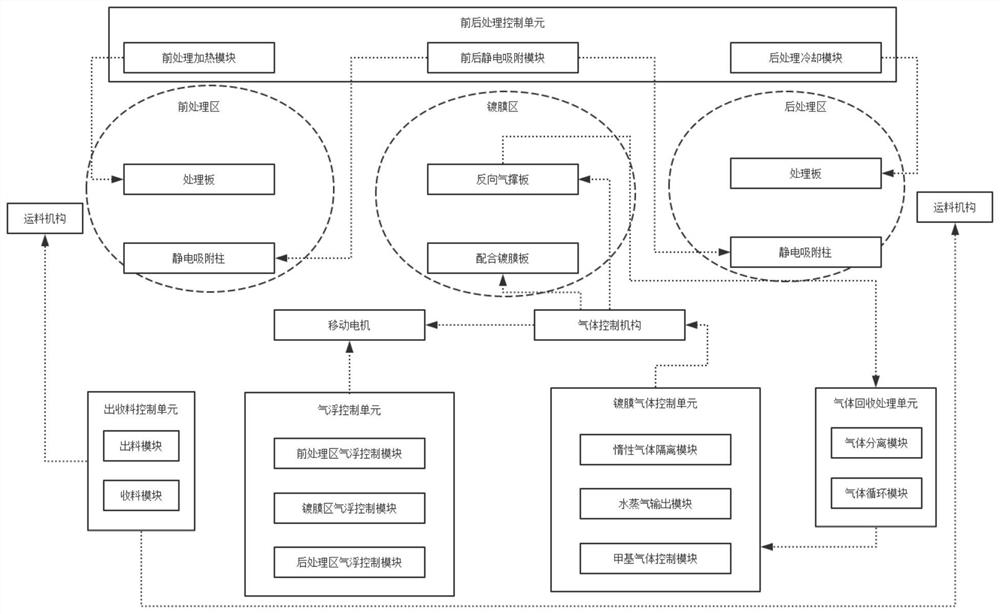

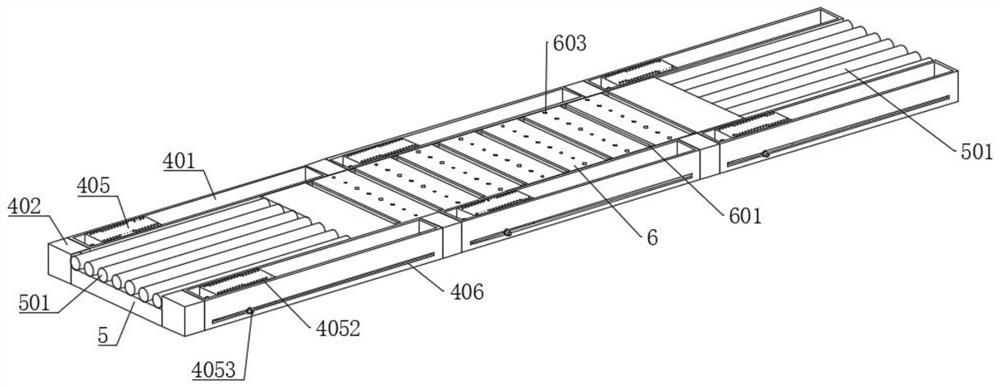

[0049] see Figure 1-12 , an air flotation type high-efficiency coating equipment for photovoltaic panels, including an equipment box 1, the upper end of the equipment box 1 is divided into a pre-processing area, a coating area and a post-processing area from left to right, the pre-processing area, the coating area and the A pair of matching air flotation track assemblies 4 are installed in the post-processing area. A pair of processing boards 5 are fixedly installed on the upper end of the equipment box 1. The two processing boards 5 are respectively located in the pre-processing area and the coating area. The upper end of the equipment box 1 is fixed A coating plate 6 is installed, and the coating plate 6 is located in the coating area. The upper end of the equipment box 1 is fixedly connected with the reaction cover 3 located on the upper side of the coating plate 6, and the lower end of the reaction cover 3 is fixedly connected with a reverse air support plate matching the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com