Vegetable meat stuffing and preparation method thereof

A meat stuffing and plant technology, applied in the field of plant meat stuffing and its preparation, can solve problems such as excessive difference, and achieve the effects of strict proportioning, scientific formula and rich nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

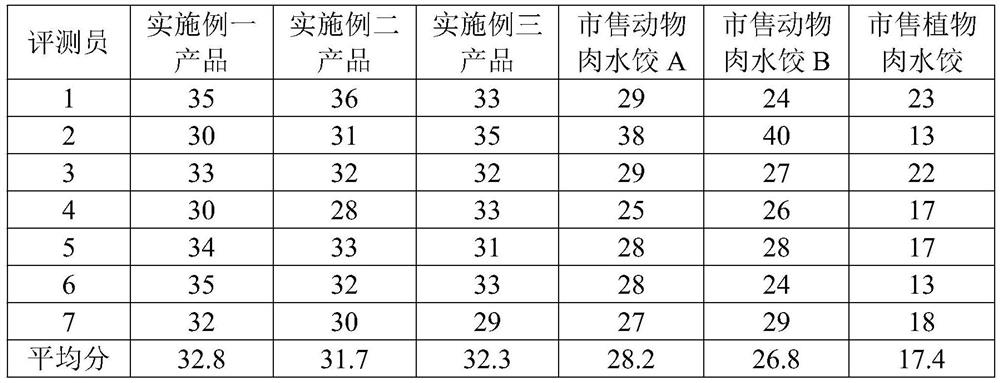

Embodiment 1

[0027] The invention proposed a plant meat, including the following weight percent raw materials: 18% of the sunflower oil, 28% of the pea filamentous tissue protein, 2% phosphate double starch, 2%, methylcellulose 2%, pea fiber powder 1%, red beet powder 1%, food flavor 1.2%, salt salt 3%, the margin is ice water.

[0028] Its preparation method includes the following steps:

[0029] S1, according to the percentage of weight, 3% of the raw sunflower oil, 28% of the pea filament tissue protein, 2% phosphate double starch, 2% of pea separation protein powder, methylcellulose 2%, pea fiber powder 1% 1% of the red beet powder, 1.2% of the flavor, 3% salt, the margin is ice water, spare;

[0030] S2, add the phosphate double starch, pea fiber powder, pea fiber powder, pea fiber powder, and ice water in step S1, stir evenly, add sunflower oil, eat flavor, salt and red sweet powder, stir until the filling is flare And non-stick device;

[0031] S3, the proportion of pea separation prote...

Embodiment 2

[0034] The invention proposed a plant meat, including the following weight percent raw materials: corn oil 15%, pea filamentous tissue protein 25%, potato starch 4%, pea separation protein powder 3%, Tg enzyme 5%, pea fiber 3% of the powder, 3% of the red beet powder, 1.5% eating flavor, salt 75%, and the margin is ice water.

[0035] Its preparation method includes the following steps:

[0036] S1, according to the percentage of weight, 3% of the raw corn oil, 25% of the pea filamentous tissue protein, 4% potato starch, 3% of pea separation protein powder, 5%, pea fiber powder 3%, red beet powder 3 %, Food flavor 1.5%, salt salt 3.5%, margin is ice water, spare;

[0037] S2, add the potato starch, pea fiber powder and ice water in step S1 to the chopper, stir even after mixing, add corn oil, eat flavor, salt and red sweet powder again, until the filling is viscous and not sticky Equipment;

[0038] S3, the proportion of pea separation protein powder is added to the pea filament t...

Embodiment 3

[0041] The invention proposed a plant meat, including the following weight percent raw materials: 13% sunflower oil, 23% of the pea granules, 2% phosphate double starch, 5% pea separation protein powder, methylcellulose 8 %, Pea fiber powder 1%, 1% red beet powder, 1.8% edible flavor, 4% xylitol, and the margin is ice water.

[0042] Its preparation method includes the following steps:

[0043] S1, according to the percentage of weight, 13% of the raw sunflower oil, 23% of the pea particles, 2% phosphate double starch, 5% of pea separation protein powder, methylcellulose 8%, pea fiber powder 1%, 1% of the red beet powder, 1.8% edible flavor, 4% xylitol, the margin is ice water, spare;

[0044] S2, add the phosphate double starch, pea fiber powder, pea fiber powder, pea fiber powder and ice water in step S1, stir well, add sunflower oil, edible flavor, xylitol and red sweet powder, until the filling stick Film and non-stick device;

[0045] S3, the proportion of pea separation prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com