Solid-liquid separation centrifuge tube for fly ash modification

A solid-liquid separation and centrifuge tube technology, applied in filtration separation, separation methods, laboratory containers, etc., can solve the problems of reduced work efficiency, no filter, time consumption, etc., to reduce the probability of manual errors, reduce The sample is the effect of loss, improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

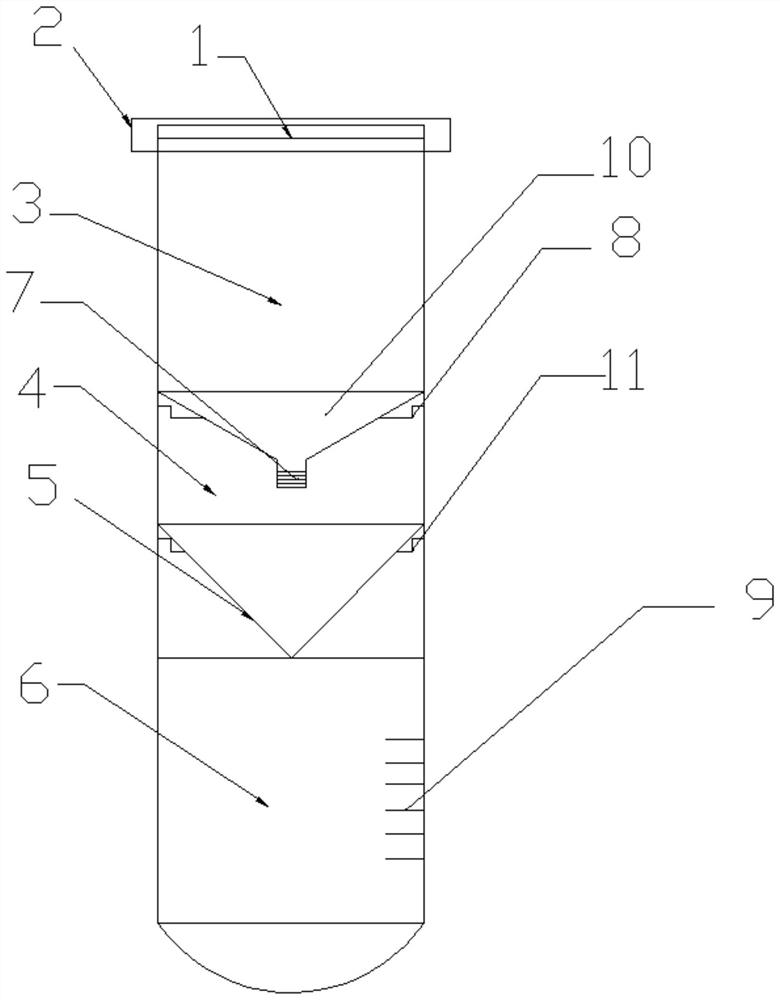

[0021] In this embodiment, the centrifugal filtration operation is mainly performed on the solid-liquid mixture; figure 1 As shown, the mixture is added to the sampling tube 2, and the centrifuge tube cap 1 is covered, and the filtration flow rate and the filtration speed of the mixture are adjusted by adjusting the screw regulator 203 in combination with the density of the mixture and the set speed of the centrifuge; the mixture Under the action of centrifugal force, pass through the separation funnel 10, and drip into the filter tube 4 below under the control of the screw regulator 7, and filter through the filter paper on the filter bracket 5, the retained particulate matter can be intercepted by the filter paper, and in After the centrifugal filtration is finished, the filter paper can be taken out to collect the retained solid particles, and the filtrate passes through the filter paper and enters the collection tube 6 for collection.

Embodiment 2

[0023] This embodiment is mainly used for the modification of fly ash. On the basis of the previous operation, solid-liquid separation is carried out to the fly ash after the modification in the previous stage, and the fly ash is retained on the filter paper of the filter bracket 5. After the centrifugation, remove the socket-type collection tube 6, replace the new collection tube 6 and insert it again, then remove the sample tube 3, insert a new sample tube 3, open the centrifuge tube cover 2, according to the modification experiment Requirements, add deionized water or dehydrated ethanol that needs to be used for modification in the sampling pipe 3, then adjust the screw regulator 7, so that it can filter the fly ash in the filter paper on the filter holder 5 under the action of centrifugal force Spray rinsing, modifying fly ash, acid-base modification can also be carried out at the same time, just need to replace the acid-resistant or alkali-resistant container, the liquid u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com