Coating treatment process for protective paint on surface layers of printed PCBs

A PCB board and surface layer technology, which is applied in the field of protective paint coating treatment process on the surface of printed PCB boards, can solve the problems that the surface contour of the PCB board cannot be sprayed, cannot be fully sprayed, and the surface of the PCB board is coated with dead angles, etc., so as to improve oil coating The effect of dipping in oil quickly, increasing activity, and avoiding leakage of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

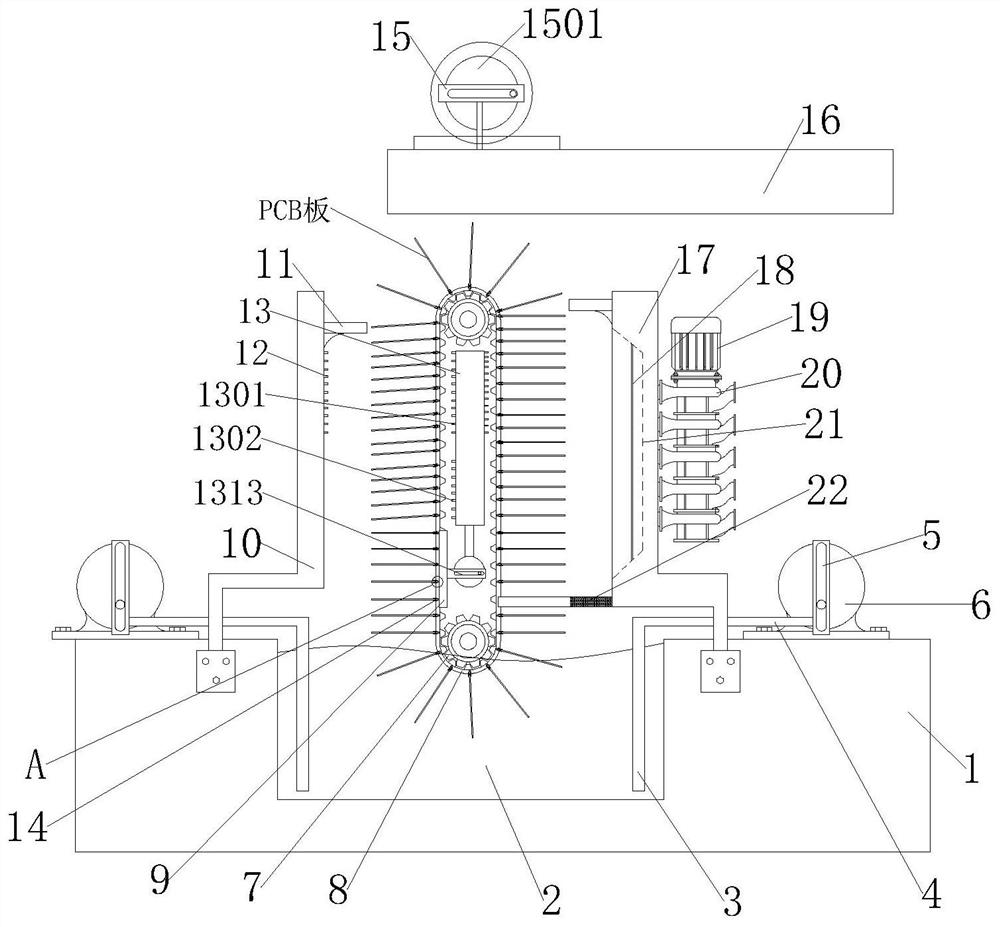

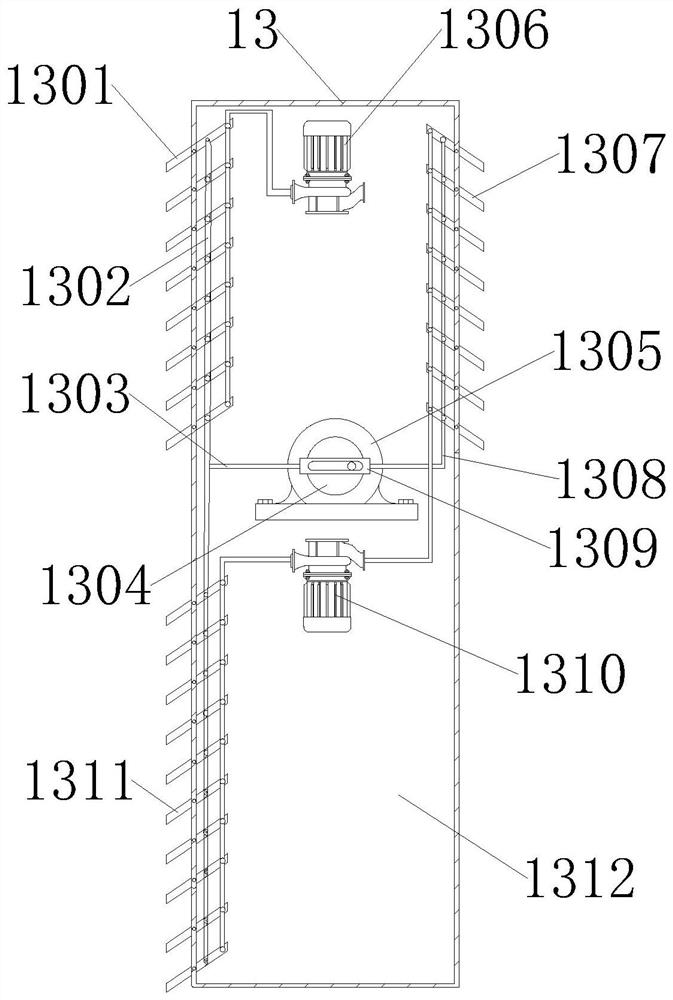

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

[0046] see Figure 1-5 It is a schematic diagram of the overall structure of the surface protection paint coating treatment process of a printed PCB board;

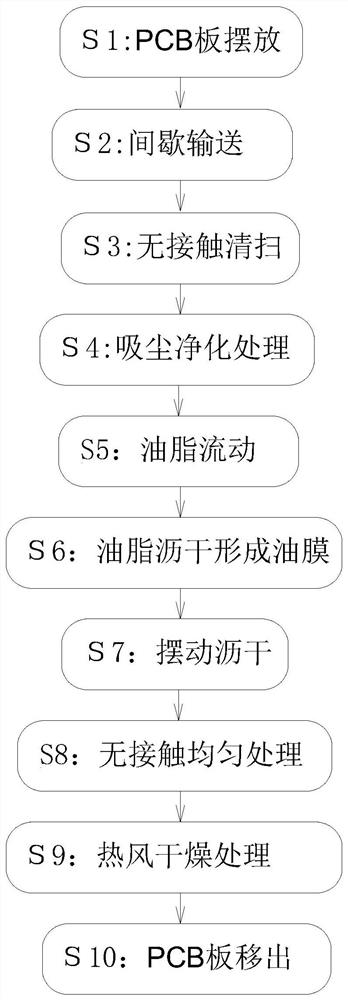

[0047] A kind of printed PCB board surface layer protective paint coating process is characterized in that, comprises the following steps:

[0048] S1. PCB board placement: place the PCB boards whose surface needs to be coated with grease upright on the automatic feeder, and install and fix each PCB board on the conveyor chain in an orderly manner through the automatic feeder, and the adjacent two PCB boards The distance between them is 10-15 cm;

[0049] S2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com