Continuous flat pressing process for light facing oriented strand board

An oriented strand board, lightweight technology, used in flat products, manufacturing tools, wood processing appliances, etc., can solve problems such as difficulty in meeting industry standards, unqualified internal bonding strength, low core density, etc., to achieve convenient operation and easy promotion. , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

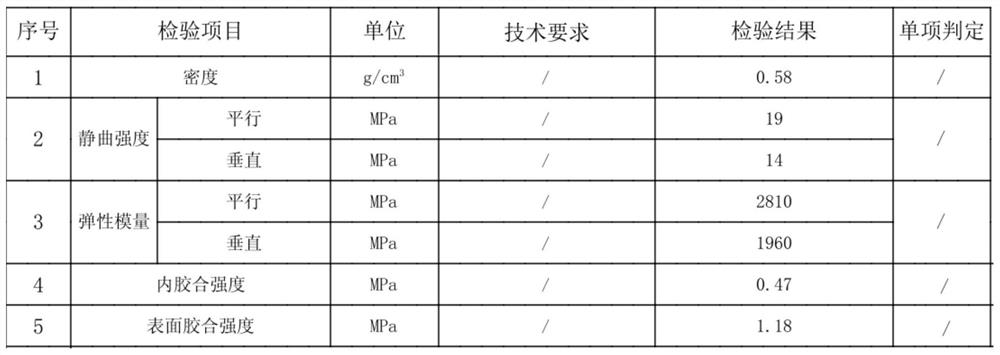

Embodiment 1

[0045] A layered hot-pressing process for preparing lightweight particleboard from ultra-thin large flakes, comprising:

[0046]1) Choose a density less than 0.45g / cm 3 , the form is wood edge bark or small-diameter wood whose short side is not less than 3cm, and wood with a moisture content of 38% is used as raw material

[0047] 2) Use a rotary cutter to cut the wood into ultra-thin large pieces at one time, with shavings 100mm long and 0.25mm thick.

[0048] 3) drying the shavings through a mesh belt type at low temperature to a moisture content of 10-12%;

[0049] 4) Sizing the dried shavings, the amount of sizing is 4%;

[0050] 5) Evenly pave the ultra-thin large shavings after sizing to obtain a core slab;

[0051] 6) The core layer slab is pre-pressed through the first stage of hot pressing; the core layer slab is sent to the hot press for pre-pressing to reduce the stacked thickness of the slab. The hot-pressing temperature is 190°C and the speed of the press is 31...

Embodiment 2

[0057] A layered hot-pressing process for preparing lightweight particleboard from ultra-thin large flakes, comprising:

[0058] 1) Choose a density less than 0.45g / cm 3 , the shape is wood edge bark or small-diameter wood whose short side is not less than 3cm, and wood with a moisture content of not less than 30% as raw materials

[0059] 2) Use a rotary cutter to cut the wood into ultra-thin large pieces at one time, with shavings 80mm long and 0.25mm thick.

[0060] 3) drying the shavings through a mesh belt type at low temperature to a moisture content of 10-12%;

[0061] 4) Sizing the dried shavings, the amount of sizing is 4%;

[0062] 5) Evenly pave the ultra-thin large shavings after sizing to obtain a core slab;

[0063] 6) The core slab is pre-pressed through the first stage of hot pressing; the core slab is sent to the hot press for pre-pressing to reduce the stacked thickness of the slab. The hot-pressing temperature is 170°C and the speed of the press is 310mm / ...

Embodiment 3

[0068] A layered hot-pressing process for preparing lightweight particleboard from ultra-thin large flakes, comprising:

[0069] 1) Choose a density less than 0.45g / cm 3 , the shape is wood edge bark or small-diameter wood whose short side is not less than 3cm, and wood with a moisture content of not less than 30% as raw materials

[0070] 2) Use a rotary cutter to cut the wood into ultra-thin large pieces at one time, with shavings 200mm long and 0.25mm thick.

[0071] 3) drying the shavings through a mesh belt type at low temperature to a moisture content of 10-12%;

[0072] 4) Sizing the dried shavings, the amount of sizing is 4%;

[0073] 5) Evenly pave the ultra-thin large shavings after sizing to obtain a core slab;

[0074] 6) The core slab is pre-pressed through the first stage of hot pressing; the core slab is sent to the hot press for pre-pressing to reduce the stacked thickness of the slab. The hot-pressing temperature is 220°C and the speed of the press is 310mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com