Fiber membrane bulking device and waste mask recycling and processing method

A processing method and technology of a chemical device, which are applied in the field of fiber membrane fluffing device and waste facial mask recycling and processing field, can solve the problems of low added value of products and single application field, and achieve controllable body shape, wide range of sources, and improved efficiency. The effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] S10 Recycling and classification of waste mask base fabrics: sort the pre-recycled mask base fabrics according to fiber type and color;

[0062] S20 Pretreatment of mask base fabrics: Wash and wash with water and alcohol alternately several times for the classified Class I mask base fabrics to remove impurities and stains on the surface of the base fabrics, and dry them in a blast oven;

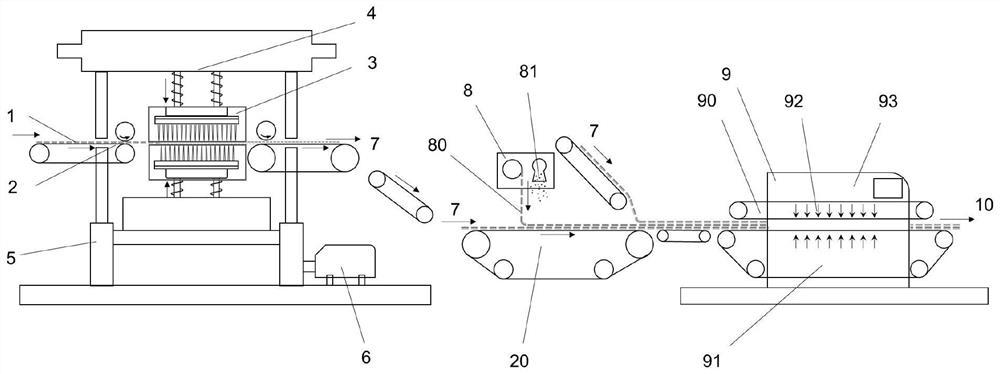

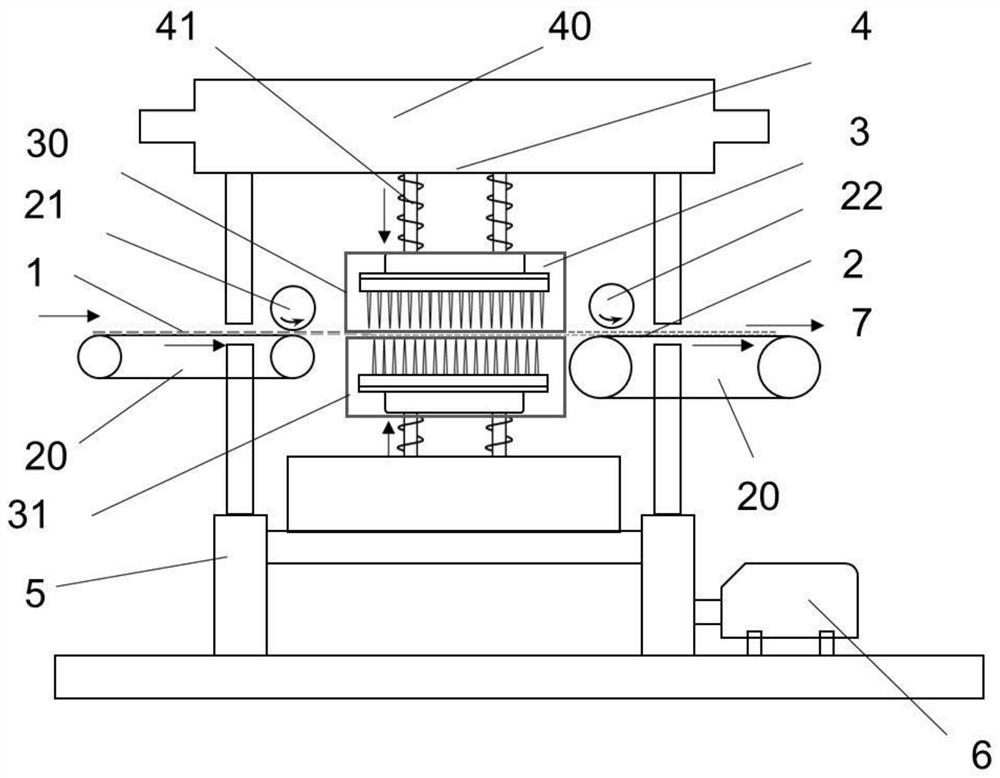

[0063] S31 passes the pretreated base fabric through the mesh curtain 20, and enters the barb fluffing system 3 under the action of the feed roller 21;

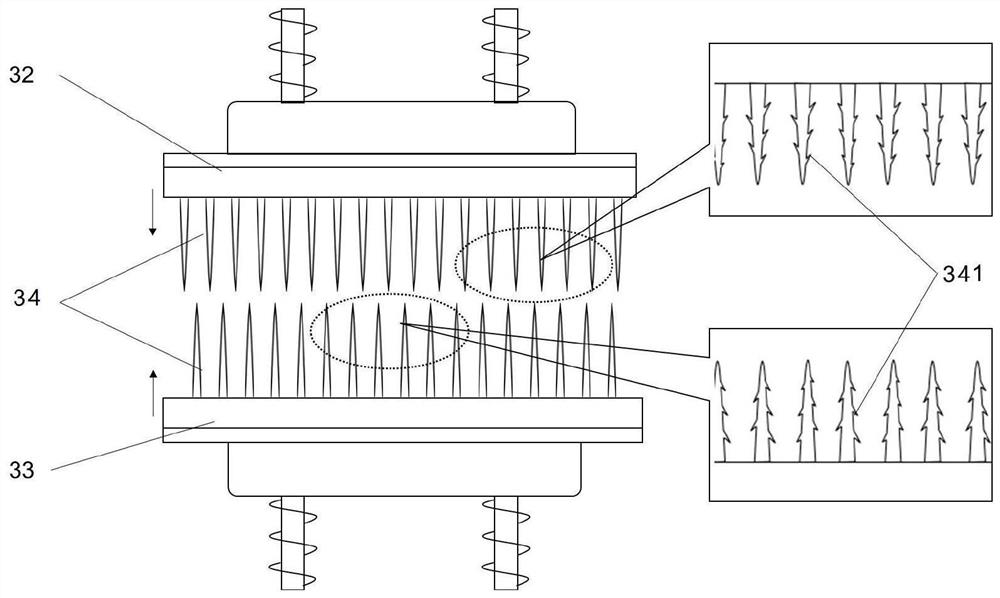

[0064] S32 In the barb area, the needle board is required to work only the upper needle board 32 along the axial direction of the base fabric; the needle density of the needle board is 500 pieces / m;

[0065] S33 When the base fabric material touches the needles 34, the barbed needles 341 pierce the inner layer of the base fabric without tangle, move to a certain depth and then rise up. , the surface of the base cloth and the fibers a...

Embodiment 2

[0071] S10 Recycling and classification of waste mask base fabrics: sort the pre-recycled mask base fabrics according to fiber type and color;

[0072] S20 Pretreatment of mask base fabric: wash and wash alternately with water and alcohol for several times to remove impurities and stains on the surface of the base fabric, and place it in a blast oven for drying;

[0073] S31 passes the pretreated base fabric through the mesh curtain 20, and enters the barb fluffing system 3 under the action of the feed roller 21;

[0074] S32 In the barb area, the needle board performs the upper needle board 32 and the lower needle board 33 to work alternately along the base fabric axis as required; the needle density of the needle board is 600 pieces / m;

[0075] S33 When the base fabric material touches the needles 34, the barbed needles 341 pierce the inner layer of the base fabric without tangle, move to a certain depth and then rise up. , the surface of the base cloth and the fibers are t...

Embodiment 3

[0081] S10 Recycling and classification of waste mask base fabrics: sort the pre-recycled mask base fabrics according to fiber type and color;

[0082] S20 Pretreatment of mask base fabrics: wash and wash with water and alcohol alternately several times for the classified III mask base fabrics to remove impurities and stains on the surface of the base fabrics, and dry them in a blast oven;

[0083] S31 passes the pretreated base fabric through the mesh curtain 20, and enters the barb fluffing system 3 under the action of the feed roller 21;

[0084] S32 In the barb area, the needle board performs the combination of the upper needle board 32 working along the axial direction of the base cloth and the lower needle board 33 working along the axial direction of the base cloth while working laterally along the conveying direction as required; the needle planting density of the needle board is 800 pieces / m;

[0085] S33 When the base fabric material touches the needles 34, the barb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com