A kind of preparation method of graphene heat dissipation composite material

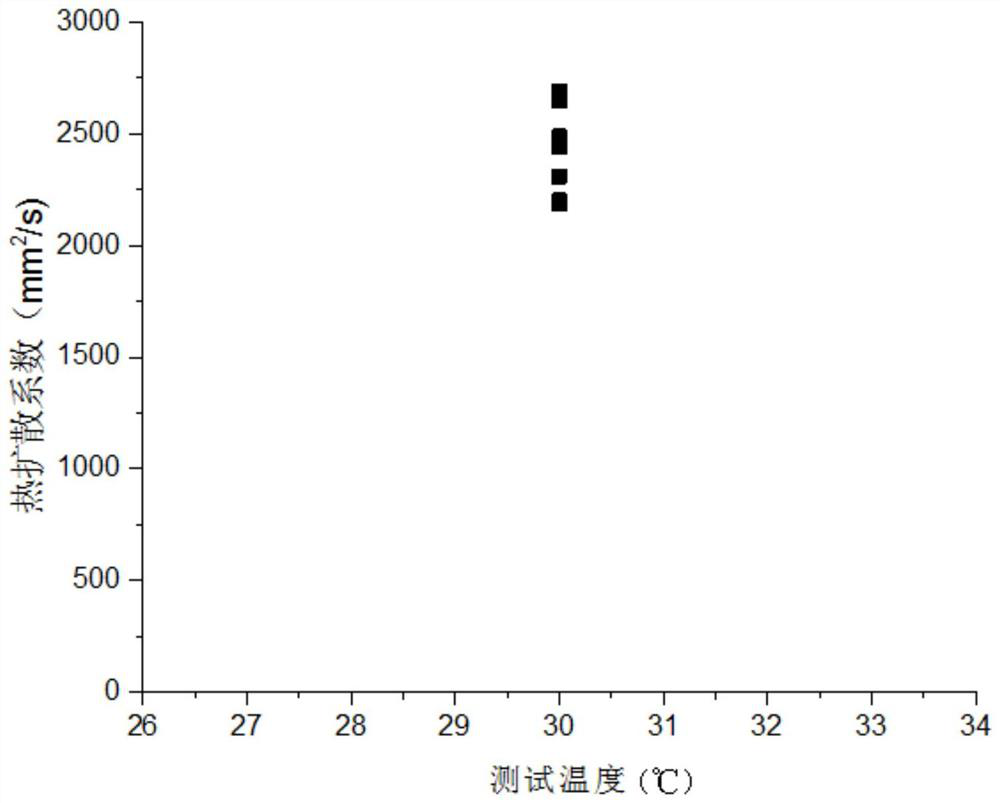

A composite material, graphene technology, applied in graphene, heat exchange materials, chemical instruments and methods, etc., can solve problems such as unsatisfactory heat dissipation performance and uneven distribution, achieve excellent thermal conductivity and heat dissipation performance, and improve heat flux. , Improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

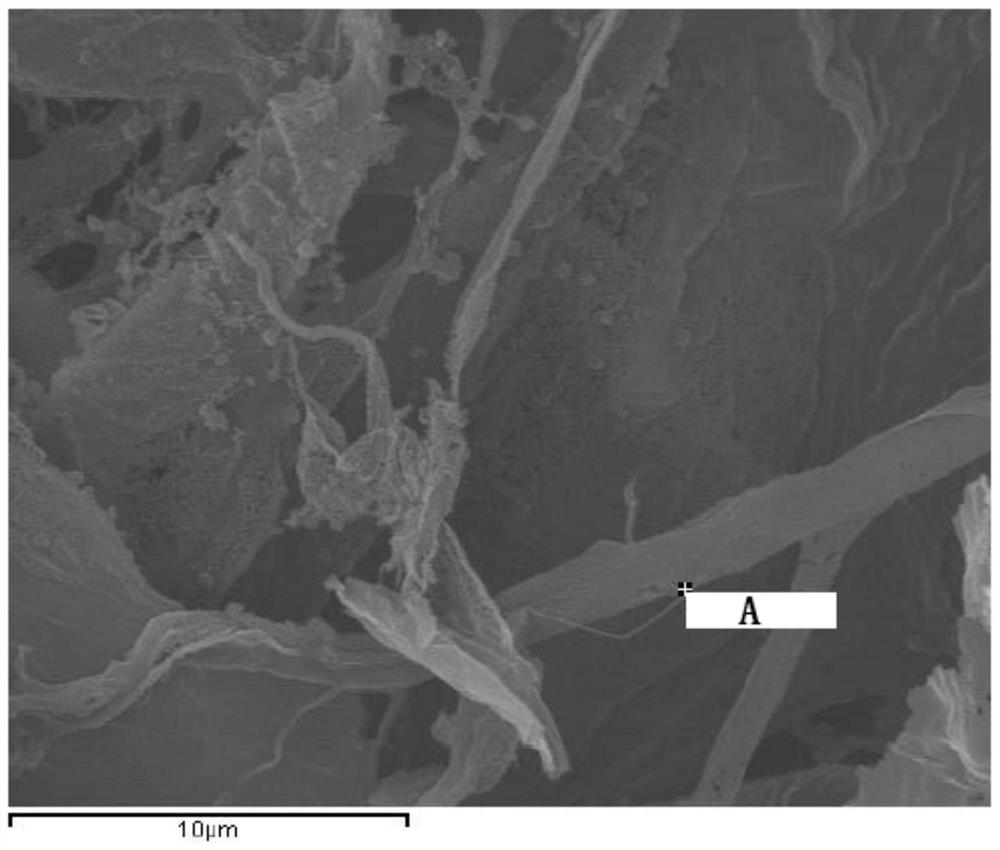

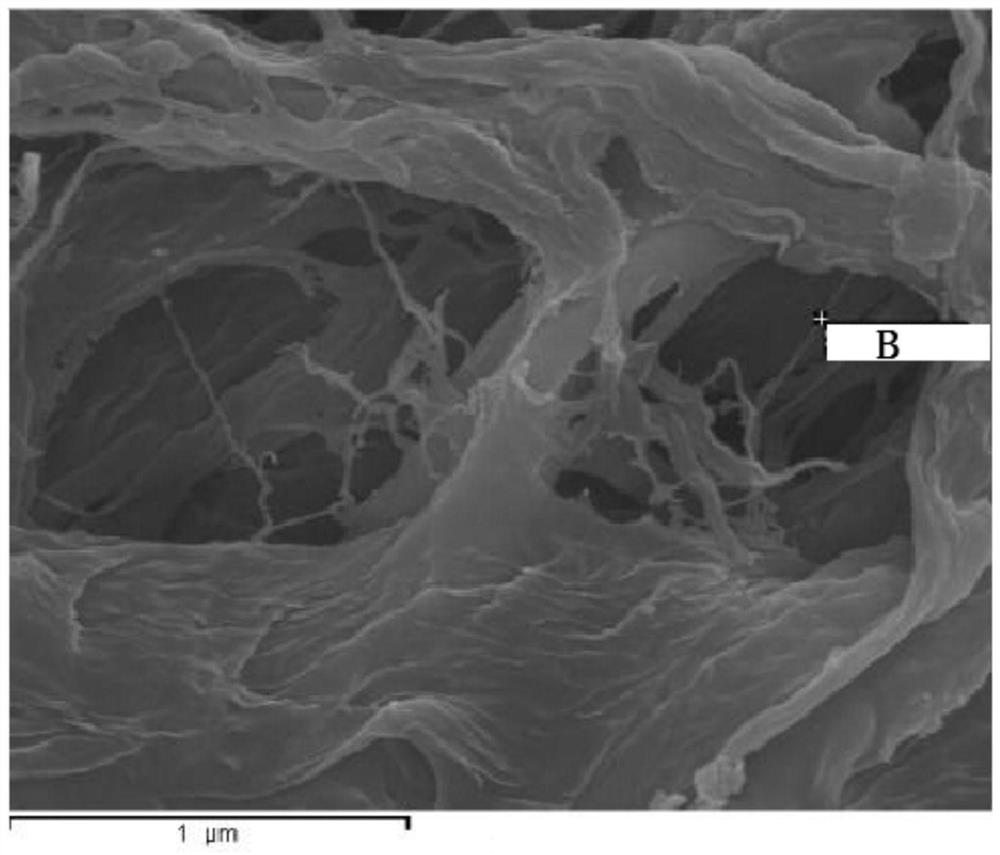

[0024] Specific embodiment one: present embodiment a kind of preparation method of graphene heat dissipation composite material, it is to carry out according to the following steps:

[0025] 1. Combining graphite powder with nano-SiO 2 Mixing, then adding to the absolute ethanol solution, using a high-speed disperser to disperse and mix to obtain a composite slurry;

[0026] Described graphite powder is natural graphite powder or expanded graphite powder;

[0027] 2. Put the composite slurry into the reaction kettle, keep it warm for 0.5h-2h under the condition of stirring speed of 300r / min-500r / min, temperature of 150℃-400℃ and pressure of 40MPa-55MPa, and then start Release the pressure until the pressure is 5MPa to 30MPa, stop the pressure relief, close the pressure valve, and obtain a composite material with high temperature and high pressure reaction;

[0028] 3. Take out the composite material of high temperature and high pressure reaction, then perform supercooling tr...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-speed disperser described in step 1 performs dispersing and mixing, specifically, the linear velocity of the dispersing head is 99m / s~140m / s and the rotating speed is 21000rpm~30000rpm Under certain conditions, disperse for 15 minutes to 8 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the natural graphite powder described in step 1 is flake graphite powder or microcrystalline graphite powder. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com