Plant extraction and distillation device based on layered separation technology

A plant extraction and distillation device technology, applied in solid separation, grain processing, food science, etc., can solve problems such as filter clogging, inconvenient cleaning of the device, affecting work efficiency, etc., to reduce vibration, improve efficiency, and promote distillation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

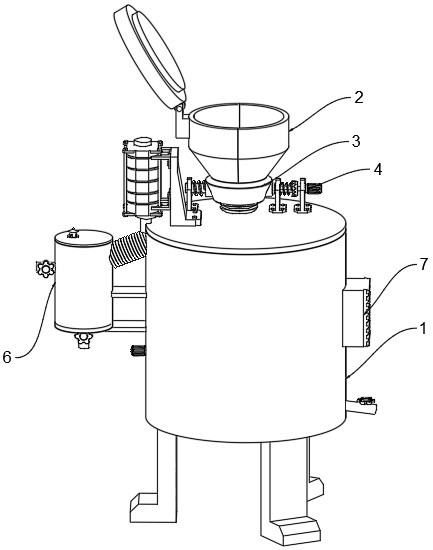

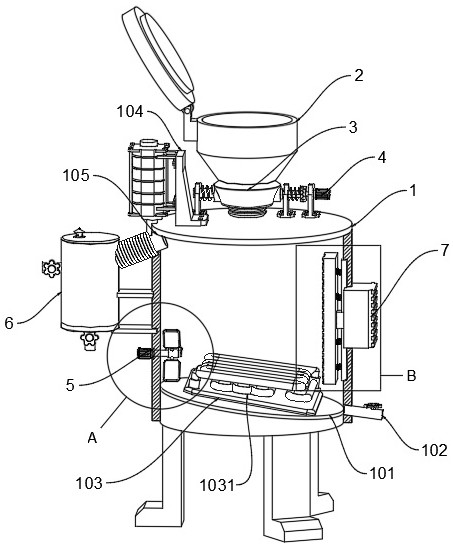

[0066] as attached figure 1 to attach Figure 8 Shown:

[0067] The present invention provides a plant extraction and distillation device based on layered separation technology, including a device body 1;

[0068] A fixing frame 104 is installed on the left end of the top surface of the device body 1, a feeding bin 2 is fixedly installed on the top of the device body 1, a flow promoting device 5 is installed on the left side of the device body 1, and a cleaning device 7 is installed on the right end of the device body 1;

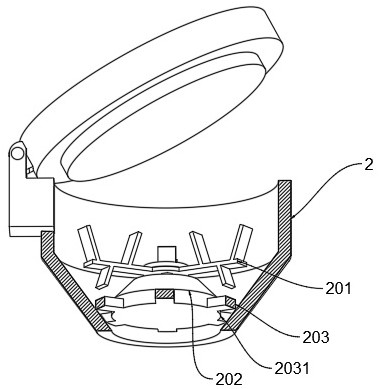

[0069] A first motor 202 is installed at the inner bottom of the feeding bin 2, and a filter device 3 is installed at the bottom of the feeding bin 2;

[0070] A vibration device 4 is installed at the left end of the filter device 3, and the bottom end of the filter device 3 is connected to the top of the device body 1;

[0071] An extraction device 6 is installed on the top of the flow promoting device 5 , and the extraction device 6 is installed in comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com