Preparation method of aluminum alloy material for semi-solid die casting of 5G cooling shell

A technology of aluminum alloy material and heat dissipation shell, applied in the field of recycled aluminum alloy, can solve the problems that will affect the structure and composition of aluminum alloy, affect production efficiency, long time, etc., and achieve the effect of improving market competitiveness and commercial value, and reducing application costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below.

[0023] Preparation method of aluminum alloy material for semi-solid die-casting of 5G heat dissipation shell, using Sr element to combine with AlF in high-temperature aluminum melt 3 Produce a chemical replacement reaction, so as to achieve the purpose of reducing the content of residual Sr elements. The method has high Sr removal efficiency, and can solve the aluminum melt gas absorption problem caused by the high Sr content in the regenerated A356 aluminum alloy.

[0024] The chemical replacement reaction is: 1.5Sr + AlF 3 = 1.5SrF 2 + Al.

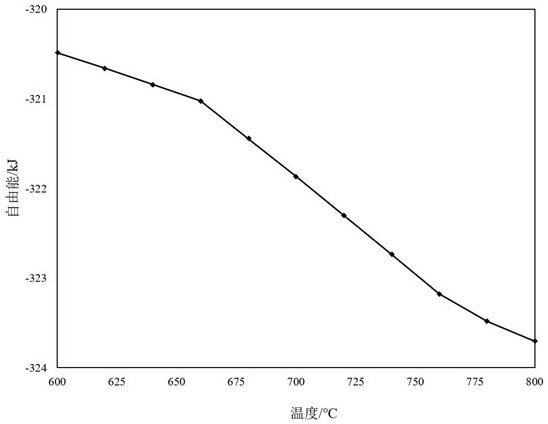

[0025] refer to figure 1 , the free energy of the reaction at different temperatures is as figure 1 As shown, it can be seen that the reaction free energy in the range of 600-800°C is less than 0, indicating that the reaction formula can proceed to the right, that is, Sr can be replaced by Al.

[0026] After the reaction, the Sr element is transformed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com