ECC reinforced steel thin-wall structure and preparation method thereof

A thin-walled structure and thin-walled technology, used in building components, manufacturing tools, building structures, etc., can solve the problems of poor fire resistance, insufficient corrosion resistance, and local buckling of thin-walled steel structures, and achieve good durability. , Reduce the cost of post-maintenance, the effect of superior crack control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

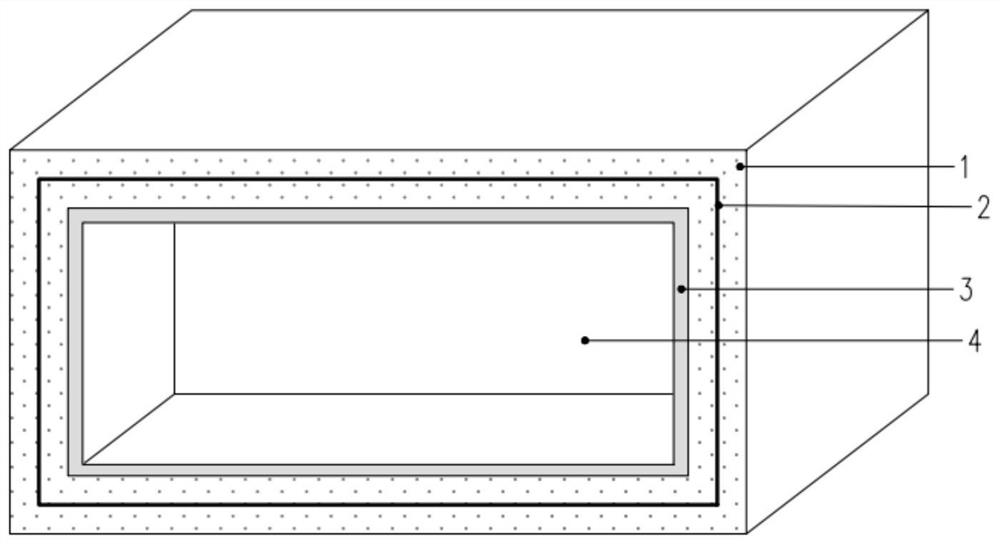

[0035] A steel thin-walled structure reinforced by ECC, comprising an ECC layer and a steel thin-walled layer arranged sequentially from outside to inside; a reinforced grid is arranged inside the ECC layer; the steel thin-walled structure is a closed structure or An open structure with openings. The thickness of the steel thin-walled layer is 2mm-40mm. In this embodiment, the thickness of the thin-walled steel layer is 10mm.

[0036] When the closed structure is adopted, the number of chambers is one. In this embodiment, the number of chambers is one.

[0037] The reinforced mesh is one or more combinations of fiber woven mesh, FRP (Fiber reinforced polymer) mesh and grid. The outer side of the steel thin-walled layer is fixed with welding studs, the welding studs are arranged in a rectangular array, and the distance between the welding studs is an integer multiple of the lattice spacing of the reinforced grid; the reinforced grid is bound to the welding studs by iron wire...

Embodiment 2

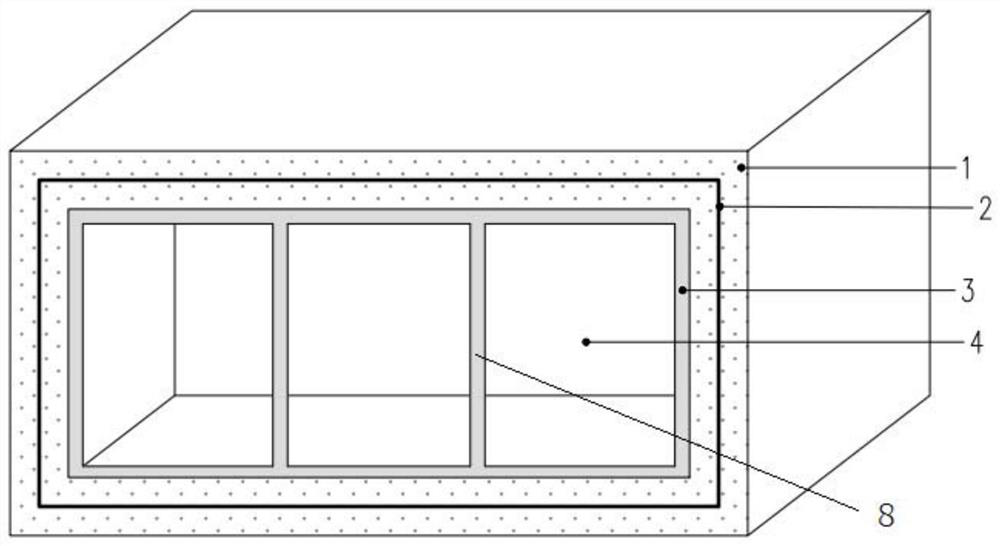

[0045] When the closed structure is adopted, the number of chambers is at least two, and the chambers are separated by partitions, and the material of the partitions is the same as the thin-walled steel layer. In this embodiment, the steel thin-walled structure adopts a closed structure, the number of chambers is three, and the chambers are separated by partitions, and the material of the partitions is the same as that of the steel thin-walled layer. The reinforced grid in this embodiment is an FRP (Fiber reinforced polymer) grid.

[0046] Fiber reinforced composite materials (Fiber Reinforced Polymer, referred to as FRP), the existing CFRP, GFRP, AFRP, BFRP and so on. Lightweight and hard, non-conductive, high mechanical strength, less recycling, corrosion resistance.

[0047] In this embodiment, the cross-sections of the three chambers are all rectangular, and the sizes of the three chambers are the same.

[0048] In the thin-walled steel structure of this embodiment, the ...

Embodiment 3

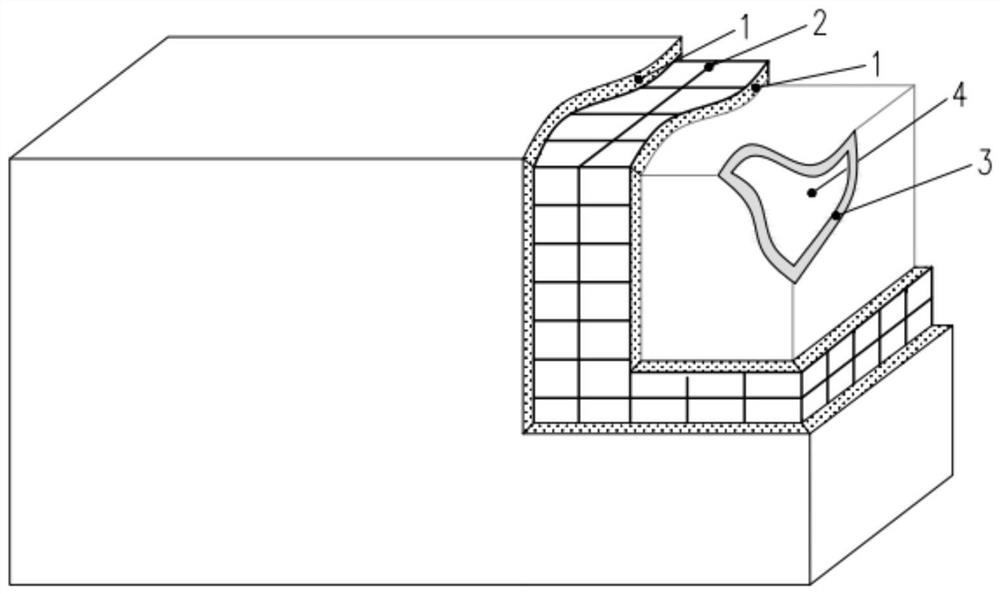

[0051] In this embodiment, the ECC layer is wrapped on the outer side of the thin-walled steel layer with variable thickness, and the thin-walled steel layer is set with variable thickness. In this embodiment, the ECC layer is wrapped with variable thickness on the outer side of the steel thin-walled layer. When the outer ECC layer is thick enough, the local bending stiffness is relatively large, so that the outward local buckling of the steel pipe can be prevented more effectively. Steel thin-walled layer variable thickness setting, according to the change of ECC layer thickness, the thickness of the steel thin-walled layer changes accordingly, cooperates with the constraints of the ECC layer on itself, and avoids internal stress changes, thereby avoiding insufficient strength of the steel thin-walled structure when it is alone compressed The problem of high height and insufficient rigidity.

[0052] The parts not mentioned in this embodiment are the same as those in Embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com