Waterproof coating and non-dripping tarpaulin

A water coating, tarpaulin technology, applied in tents/canopies, building types, buildings, etc., can solve the problems of manual transportation of tarpaulins, poor water vapor absorption, friction damage to tarpaulins, etc. The effect of transportation, convenient installation and replacement, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

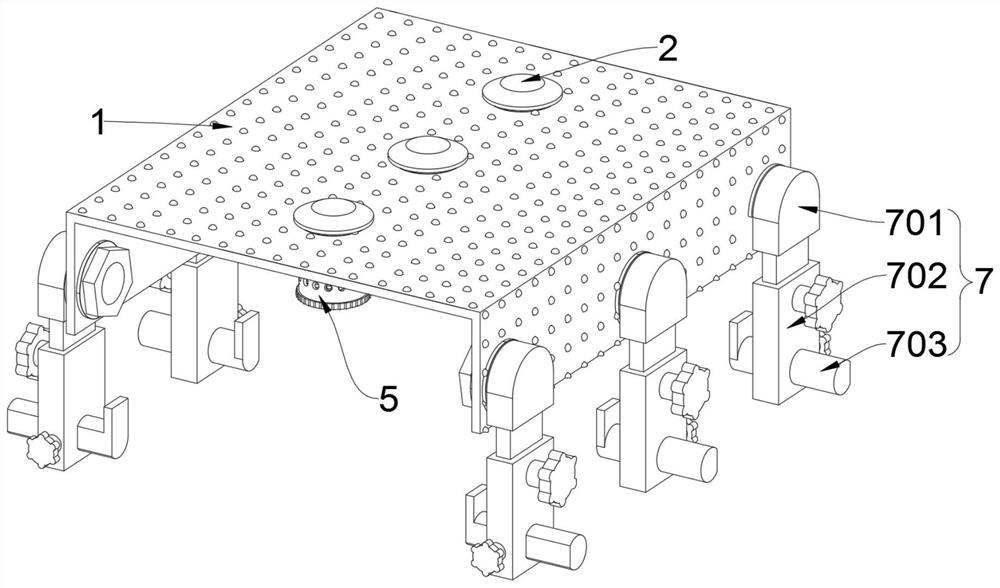

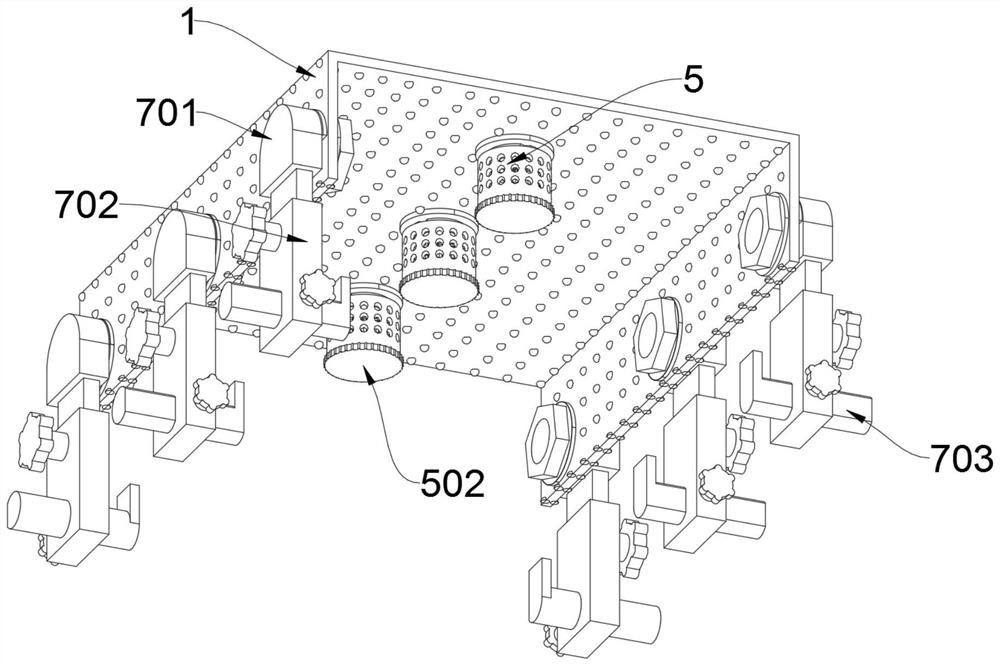

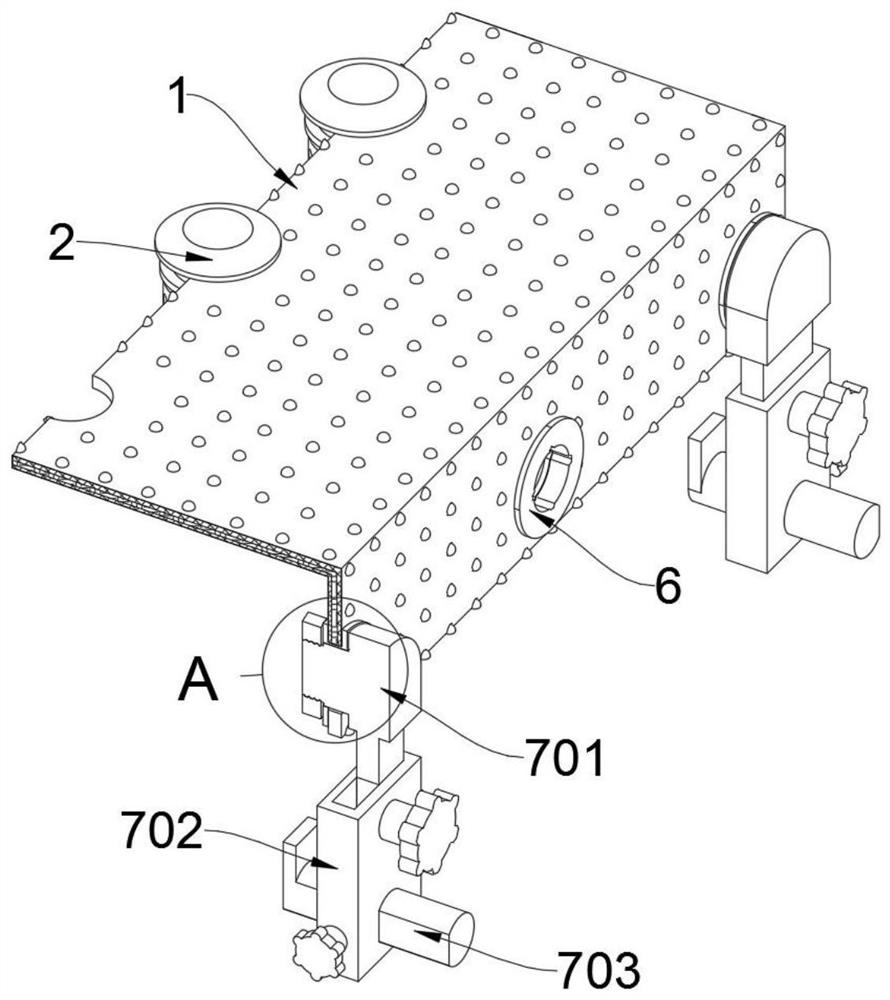

[0037] as attached figure 1 To attach Figure 10 Shown:

[0038]The present invention provides an anti-staining coating and a non-drip tarpaulin, including a tarpaulin 1; a set of clamping fixing seats 2 are installed on the tarpaulin 1, and a lip sealing ring 3 is installed on the bottom of the fixing seat 2; A clamping connection structure 4 is installed on the inner side of the fixed seat 2, and a chamfer is provided on the top of the fixed seat 2. A loading bottle body 5 is installed on the connecting structure 4 through bolts; Buckle 6, and each bottom mounting buckle 6 is equipped with a locking structure 7; the loading bottle body 5 is provided with a group of conical holes distributed in a circular array, and the major diameter of the conical holes faces outward, and the conical holes are upward It is set on the loading bottle body 5 with an inclination of 30 degrees. When in use, the conical hole on the loading bottle body 5 has the effect of air flow, and the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com