Overlay measurement method and system in integrated circuit chip manufacturing process

A technology of overlay measurement and manufacturing process, applied in the field of overlay measurement, which can solve problems such as lens distortion, overlay error, wafer stage shaking, etc., to improve stability and accuracy, improve measurement efficiency, and shorten measurement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] An overlay measuring method in the manufacturing process of an integrated circuit chip according to the present invention comprises the following steps:

[0073] For each process level of the chip manufacturing process, collect image data of each overlay mark on the wafer or collect overlay measurement data in some areas on the wafer.

[0074] Use the collected overlay-marked image data or overlay measurement data to establish machine learning models respectively, specifically: use the collected overlay-mark image data to establish an overlay-mark image processing model, and use the collected overlay-measurement data to establish an overlay measurement data prediction model.

[0075] like Figure 7 As shown, the process of building a machine learning model is shown. First, collect or generate input data 1000 required to establish a machine learning model through process tests or simulation methods. In this embodiment, the input data at least includes the names of rele...

Embodiment 2

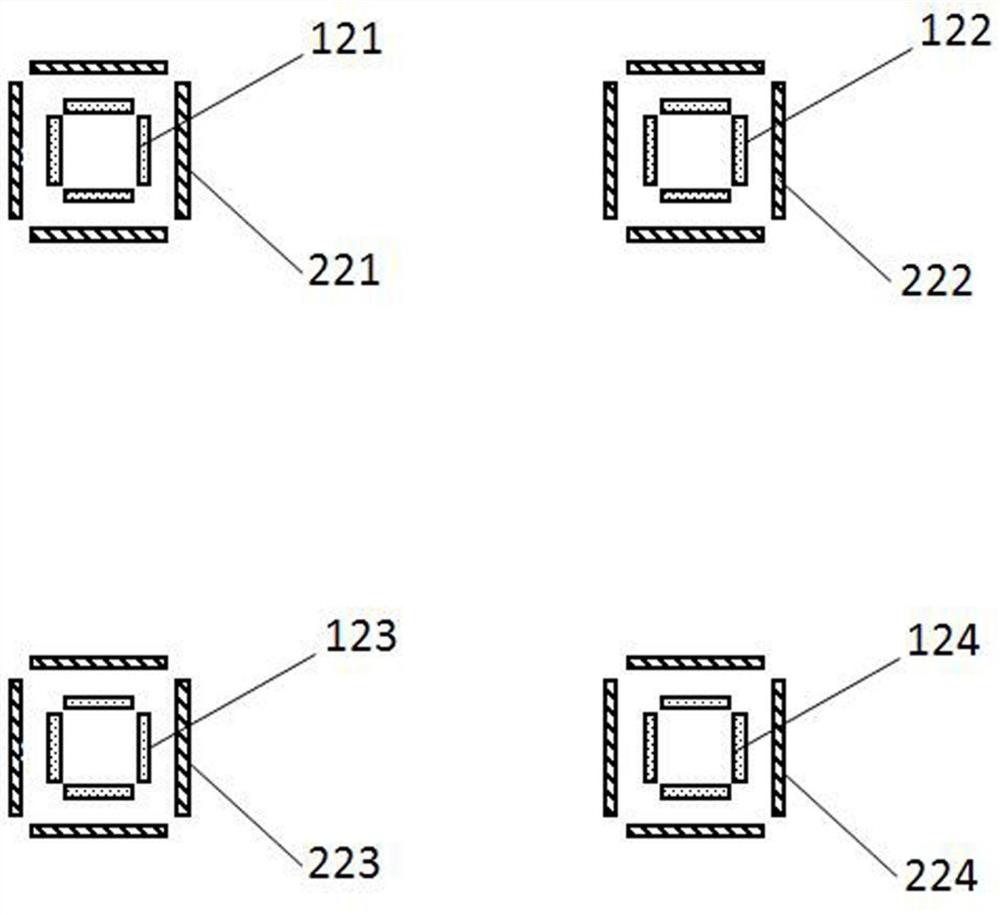

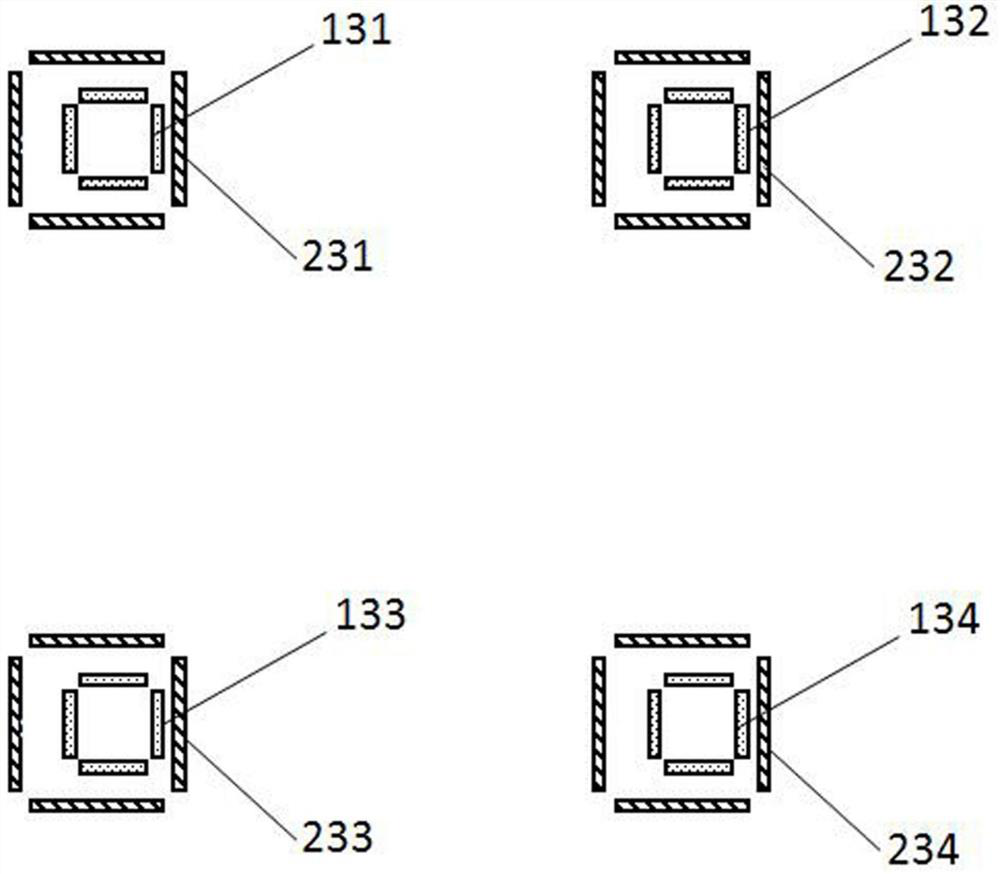

[0078] like Figure 5 As shown, the overlay marks 170 and 270 are generated at two different process levels, respectively containing four strip marks, forming a box structure. In the overlay mark 170, part of the strip mark 1701 is missing; the edge of the strip mark 1703 is not clear; in addition, the particles 1705 generated in the process are located near the overlay marks 170 and 270, which generate interference signals and affect the normality of the overlay measurement conduct.

[0079] In this embodiment, the image processing model for overlay marks described in Embodiment 1 is used to process the image data for overlay marks to solve the problem of Figure 5 problem shown. like Figure 8 As shown, the steps include the following:

[0080] For each process level, collect each overlay mark image on the wafer as the input data 2000 for overlay measurement, the input data described in this embodiment is the same as the input data in embodiment 1;

[0081] Carry out pr...

Embodiment 3

[0085] As a more preferred solution than Example 2, such as Figure 9 As shown, the difference between this embodiment and embodiment 2 is that an online model training function is added, specifically:

[0086] For each process level, collect each overlay mark image on the wafer as the input data 3000 for overlay measurement, the input data described in this embodiment is the same as the input data in embodiment 1;

[0087] Perform preprocessing on the above-mentioned input data 3000, the preprocessing described in this embodiment is the same as that in Embodiment 1;

[0088] The above-mentioned preprocessed data 3100 is input to the overlay mark image processing model 3200, and the overlay mark image processing model 3200 processes the overlay mark image through a machine learning method, such as Figure 5 As shown, the deployed overlay labeling image processing model 3200 can reconstruct the striped labeling pattern 1702 and blurred pattern 1704, and remove the pattern of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com