Steam curing system for anti-half-curing production of aerated concrete

A technology for aerated concrete and concrete, which is applied to ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of generating raw materials, incomplete steam curing and drying of aerated concrete plates, etc., and achieves release of adhesion and simple structure. Reliable and prevent clipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

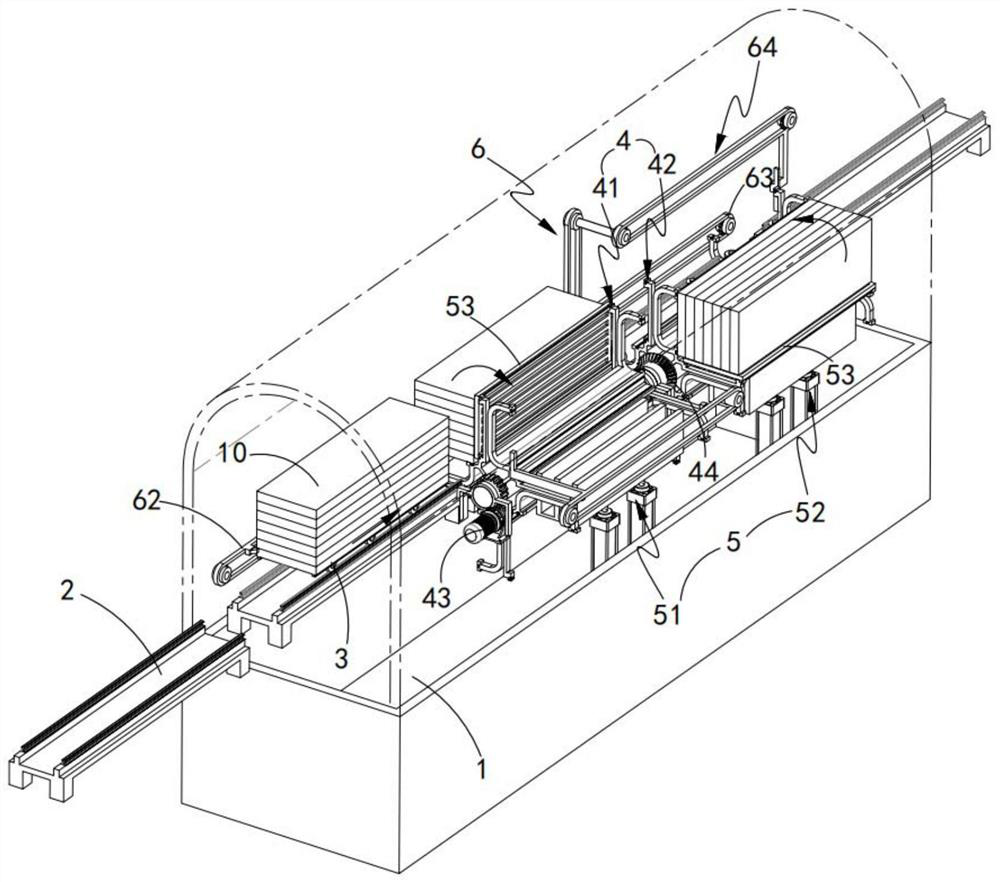

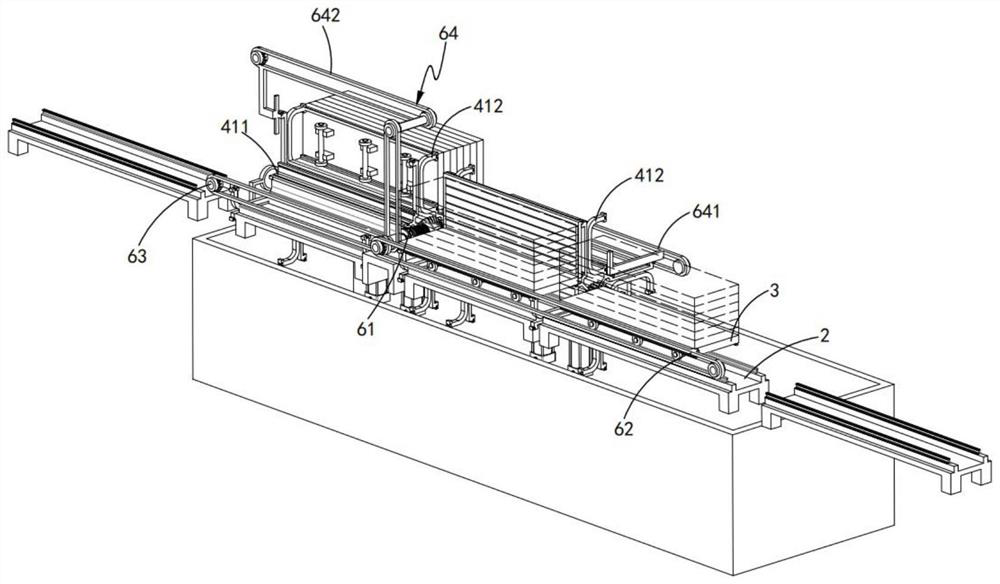

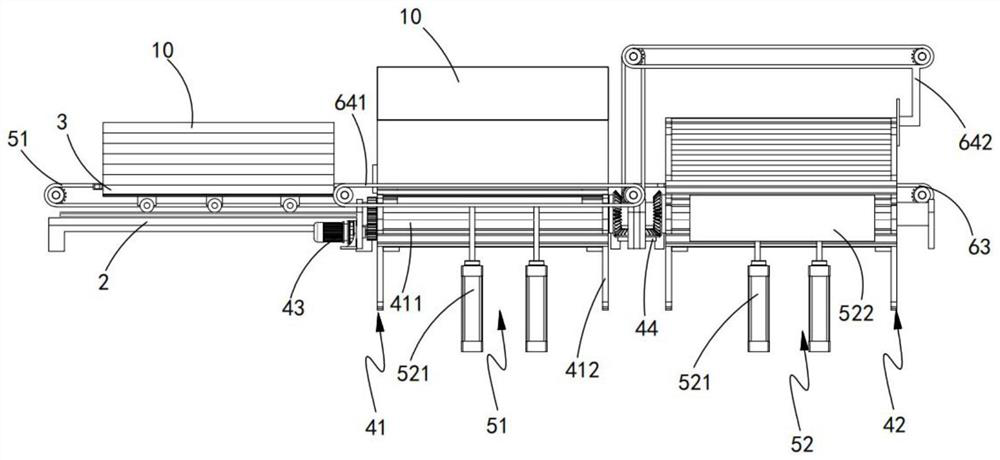

[0036] Such as Figures 1 to 3 As shown, a steam-curing system for anti-crowding production of aerated concrete includes a steam-cured 1, a conveying track 2 penetratingly arranged along the length direction of the steam-cured 1, and a conveyor track 2 arranged on the conveying track 2. The carrier vehicle 3 carrying concrete building materials 10 is characterized in that it also includes a turning mechanism 4 and a dislocation jacking mechanism 5, and the turning mechanism 4 drives the carrier vehicle 3 and the concrete building materials 10 to turn over along a vertical plane. The jacking mechanism 5 lifts the overturned concrete building materials 10 at intervals to form dislocations.

[0037] It should be noted that the carrier vehicle 3 transports the concrete building materials 10 stacked in a flat layer into the steam-cured tank 1, the turning mechanism 4 turns the concrete building materials 10 into a vertically arranged state of width, and the dislocation jacking mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com