Rubber final mixing process for internal mixer

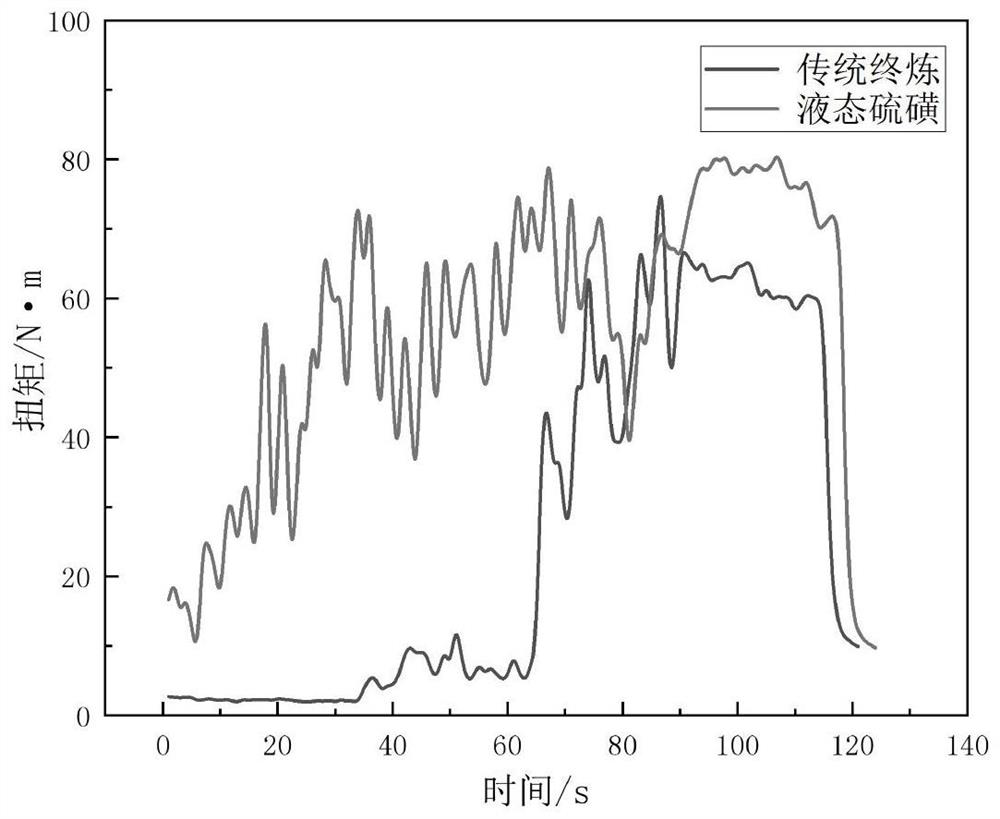

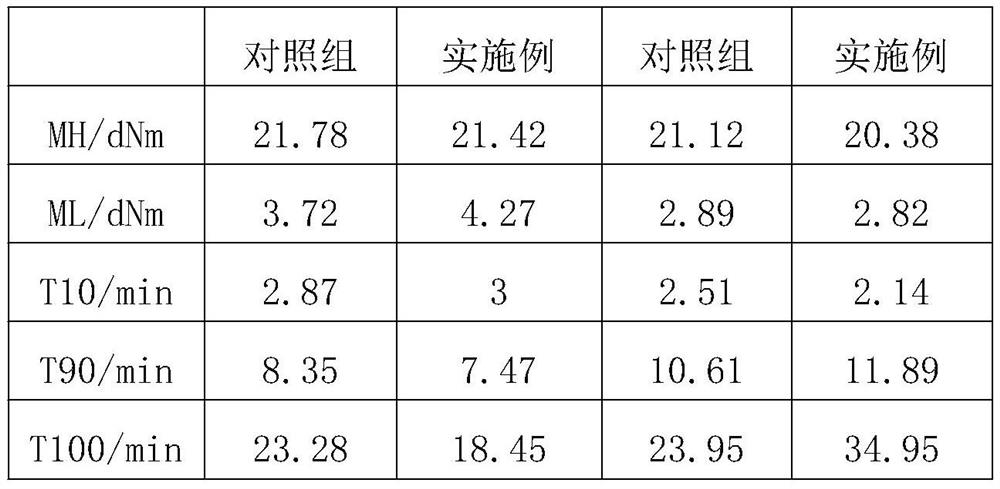

An internal mixer and rubber technology, used in the field of rubber mixing, can solve the problems of increased energy consumption, high energy consumption, and short rubber compound mixing time, so as to reduce the impact of equipment, the principle is scientific and reliable, and the final mixing energy can be reduced. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete steps of the rubber final mixing process used in the internal mixer involved in the present embodiment are:

[0020] (1) Raise the temperature of the mixing chamber with a capacity of 200 mL of the RM-200C internal mixer (using Erleng Bunbury rotor) of Harbin Hapu Electric Technology Co., Ltd. to 120 °C and wait for use;

[0021] (2) Add the sulfur into the mixing chamber with a rotating speed of 10 rpm, and drop the top bolt to keep the temperature for 30s, so that all the sulfur is transformed into a molten state; when adding sulfur, avoid the sulfur falling on the rotor, and try to let the sulfur fall on the wall of the mixing chamber. , to avoid slippage between the rotor and the rubber material, reduce the friction coefficient between the mixing chamber wall and the rubber material, and increase the feeding speed; avoid open flames and static electricity, and do not use high speed before the sulfur is melted, in order to prevent safety problems caused b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com