Preparation method of bepotastine besilate

A bepotastine benzenesulfonate and electromagnetic control technology are applied in the field of preparation of bepotastine benzenesulfonate, and can solve the problems of difficulty in adding various organic solutions, inconvenience in adding organic solutions, difficult methods for purity, and the like, Achieve the effect of easy recording and quantitative feeding, convenient feeding and saving of extraction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention discloses a preparation method of bepotastine besylate, in a specific embodiment of the invention, comprising the following steps:

[0037] S1: Put the aqueous solution of inorganic alkali into the first reaction chamber of the first reaction kettle, then add the crude product of bepotastine besylate, start the first agitator to stir, and make the crude product of bepotastine besylate Fully mixed and dispersed with inorganic alkali aqueous solution;

[0038] S2: Then open the one-way valve on the first discharge pipe to filter the liquid and flow into the bottom of the partition, then start the first electromagnetic control mechanism to energize the electromagnetic coil, the iron core generates magnetic force, and the piston is sucked downward by the iron core close, drive the piston sleeve to move downward, and open the first valve seat. At this time, both the upper and lower ends of the piston sleeve are opened, the first liquid inlet and the second liqu...

Embodiment 2

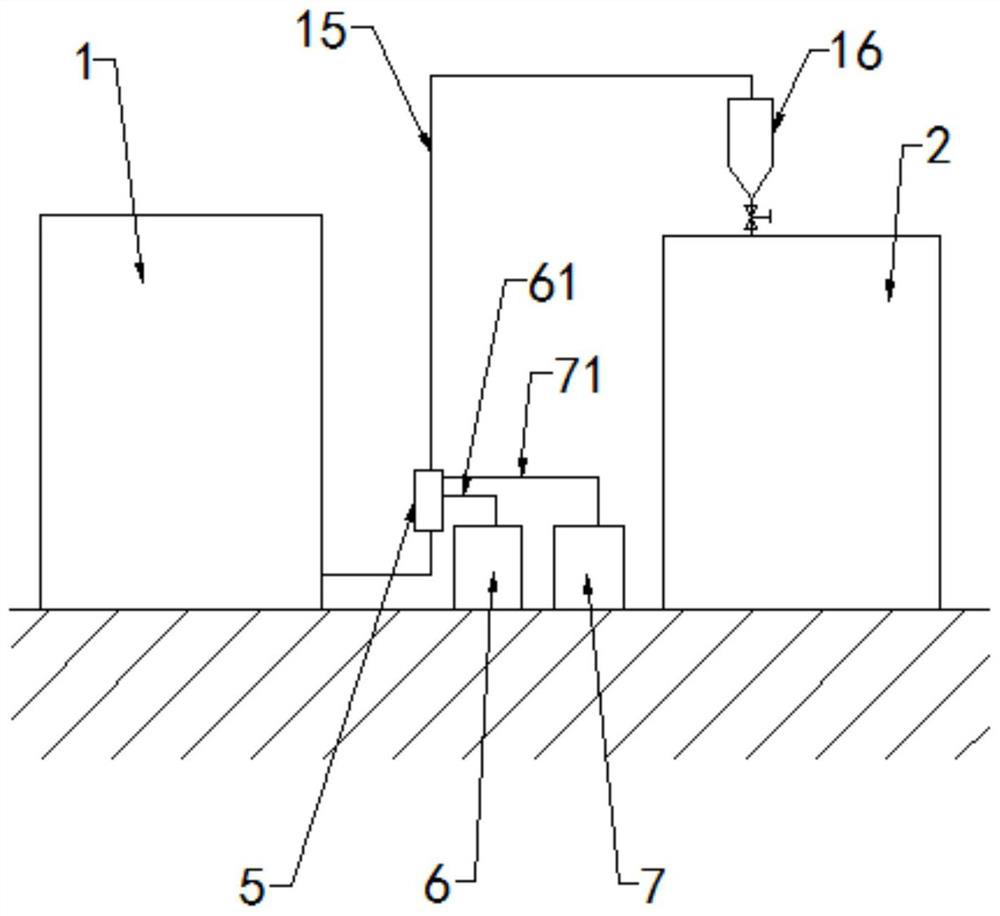

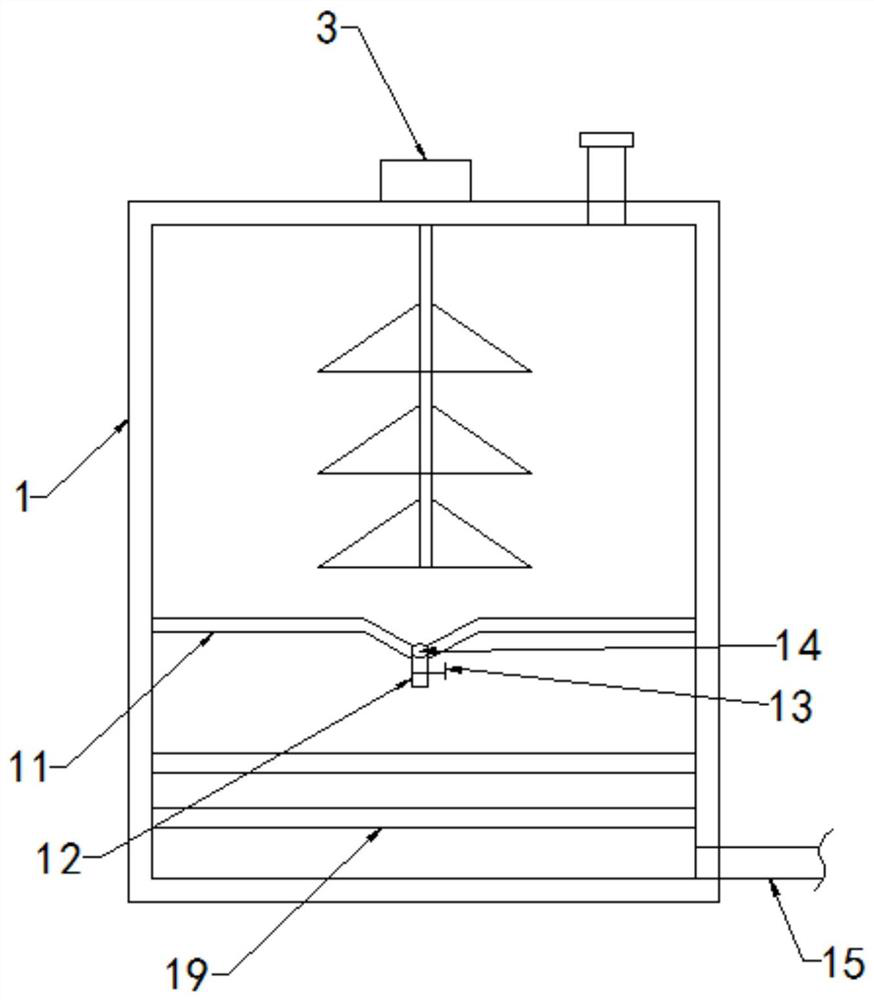

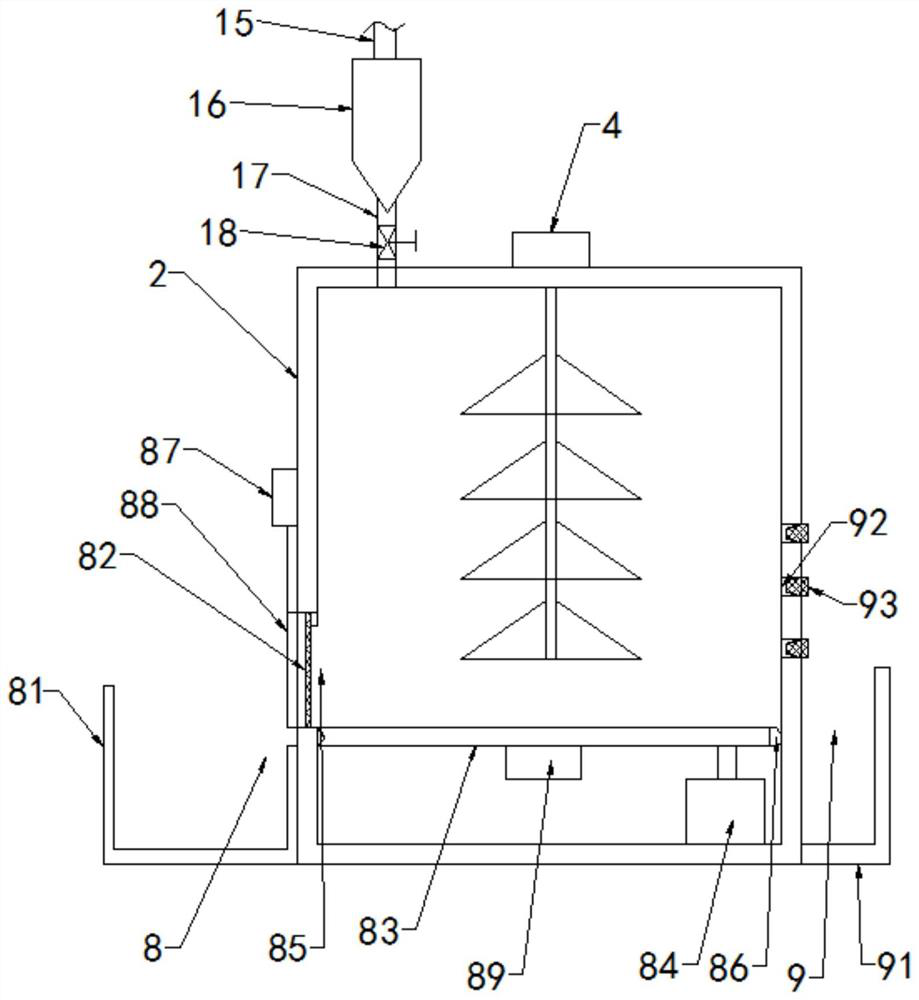

[0043] Such as Figure 1 to Figure 5 As shown, the steps in Example 1 are carried out in the first reactor 1, the second reactor 2 and the hollow drying box, wherein, the upper end of the first reactor 1 is provided with a feed port, and the first reactor 1 is provided with a feed inlet. The agitator 3 is arranged in the first reaction kettle 1, and a partition 11 is horizontally installed in the first reaction kettle 1, the first discharge pipe is installed at the lower end of the partition 11, and the one-way valve 13 is installed at the second On a discharge pipe 12, a filter element 14 is installed in the first discharge pipe 12; a connecting pipe 15 is installed on the first reaction kettle 1, and the connecting pipe 15 is located at the lower end of the dividing plate 11, and the connecting pipe 15 is provided with a liquid addition valve 5 for adding organic solution, and a liquid separator 16 is installed on the upper end of the second reaction kettle 2, and a scale is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com