MEMS flow sensor and preparation method thereof

A technology of flow sensor and heating resistance, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, instruments, etc., which can solve the problem that the heat loss type flow sensor has a large temperature influence, the differential pressure type flow sensor is complicated to install and consumes a lot of power. and volume to improve measurement accuracy and sensitivity, suppress temperature drift, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

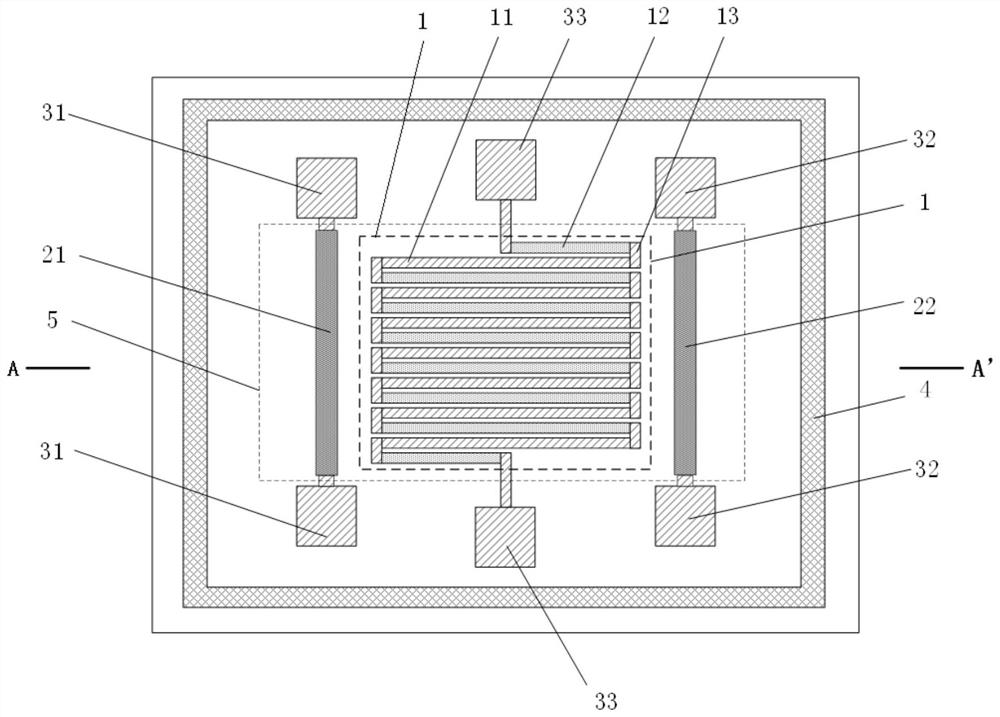

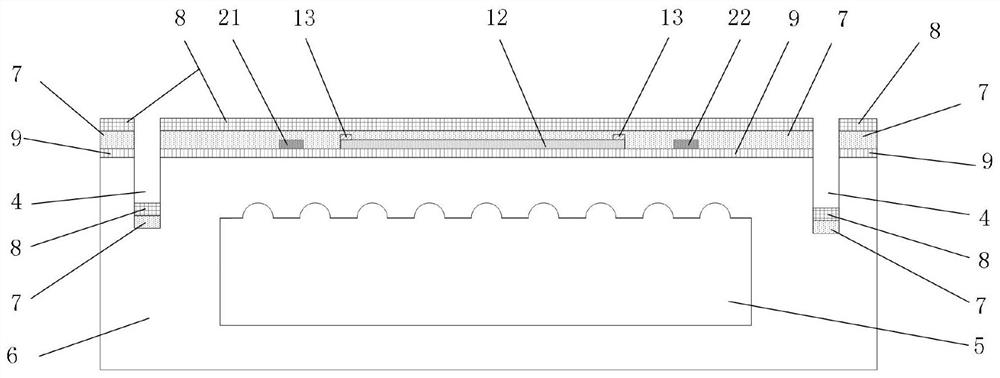

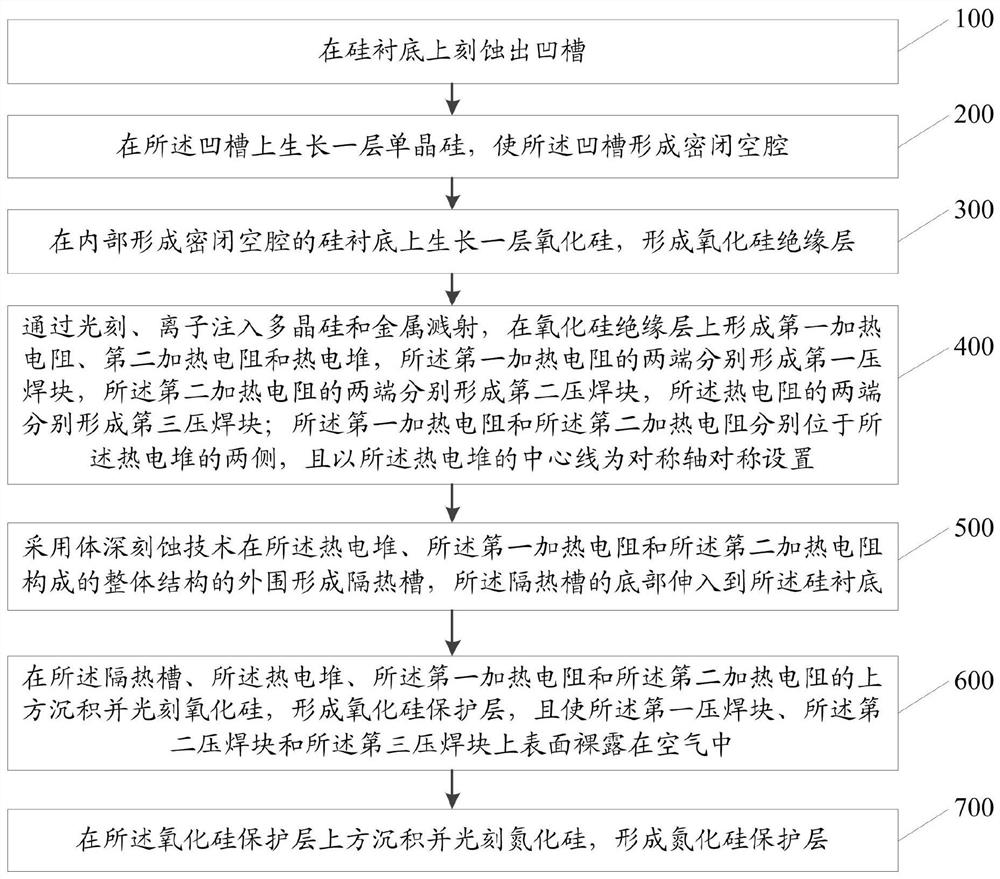

[0054] image 3 Be a kind of MEMS flow sensor preparation method flowchart of the present invention, as image 3 Shown, a kind of MEMS flow sensor preparation method comprises:

[0055] Step 100: Etching grooves on the silicon substrate.

[0056] Wherein, step 100 specifically includes:

[0057] Etching an initial groove on the silicon substrate by using an anisotropic reactive ion etching method;

[0058] Continue etching at the bottom of the initial groove by using an isotropic etching method to form the groove.

[0059] Optionally, the thermopile includes a plurality of thermocouples, each of the thermocouples is connected in series, the thermocouple includes a semiconductor arm and a metal arm, and one end of the semiconductor arm is connected to one end of the metal arm through a metal wire connection.

[0060] Step 200: growing a layer of single crystal silicon on the groove, so that the groove forms a closed cavity.

[0061] Step 300: growing a layer of silicon ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com