Preparation method of goaty-flavor-free goat milk

A technology for goat milk and mutton taste is applied in the field of preparation of goat milk without mutton taste, which can solve the problems of retaining goat milk and removing mutton taste and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Standardized preparation: according to 400g of water, 100g of goat milk powder, 0.4g of β-cyclodextrin, 0.2g of lecithin, 4g of acacia honey, 0.2g of vitamin A (retinol) and 2g of green tea extract, stir to fully dissolve .

[0041](2) Homogenization: use 30MPa operating pressure for homogenization for 10 minutes.

[0042] (3) Spray drying or pasteurization: Part of the homogenized goat milk product is spray-dried under the operating condition of 180° C. to prepare solid non-smelly goat milk powder; The pasteurization was carried out by incubating for 15 minutes under the condition of ℃, and the liquid non-smelly goat's milk was prepared.

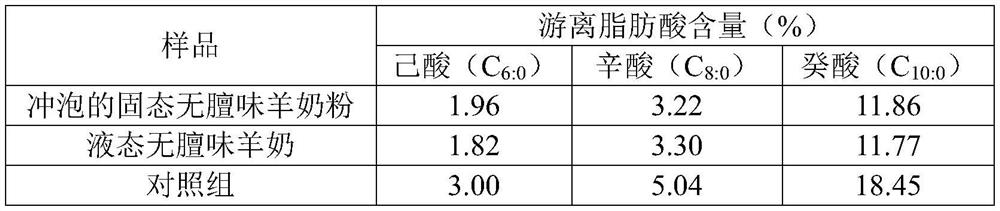

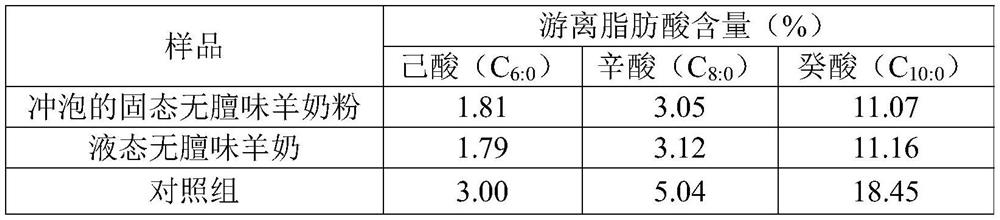

[0043] After reconstituting the finished product of solid non-smelly goat milk powder by flushing with water, compared with pure goat milk, the sensory evaluation of the intensity of the smell was carried out. The evaluation results are as follows: the original pure goat milk scored 3.2 points, and the goat milk powder scored 7....

Embodiment 2

[0048] (1) Standardized preparation: 400g of water, 100g of goat milk powder, 0.8g of β-cyclodextrin, 0.3g of lecithin, 5g of acacia honey, 0.4g of vitamin A acetate and 2.5g of green tea extract, stirred and fully dissolved.

[0049] (2) Homogenization: use 30MPa operating pressure for homogenization for 10 minutes.

[0050] (3) Spray drying or pasteurization: Part of the homogenized goat milk product is spray-dried under the operating condition of 180°C to obtain solid odor-free goat milk powder; the remaining homogenized goat milk is dried at 80°C The pasteurization was carried out by keeping the temperature for 15 minutes under the condition to prepare the liquid goat's milk without smell.

[0051] After reconstituting the finished product of solid non-smelly goat milk powder by flushing with water, compared with pure goat milk, sensory evaluation was carried out on the intensity of smell. The evaluation results are as follows: the original pure goat milk scored 3.2 points...

Embodiment 3

[0057] (1) Standardized preparation: according to 550g of fresh goat milk, 0.4g of β-cyclodextrin, 0.2g of lecithin, 4g of acacia honey, 0.2g of vitamin A palmitate and 2g of green tea extract, stir to fully dissolve.

[0058] (2) Homogenization: use 10MPa operating pressure for homogenization for 15 minutes.

[0059] (3) Spray drying or pasteurization: Part of the homogenized goat milk product is spray-dried under the operating condition of 180° C. to prepare solid non-smelly goat milk powder; The pasteurization was carried out by incubating for 15 minutes under the condition of ℃, and the liquid non-smelly goat's milk was prepared.

[0060] Comparing the liquid non-smell goat milk with the pure goat milk, the sensory evaluation of the smell intensity was carried out, and the evaluation results were as follows: the original pure goat milk scored 3.2 points, and the liquid non-smelly goat milk scored 7.5 points.

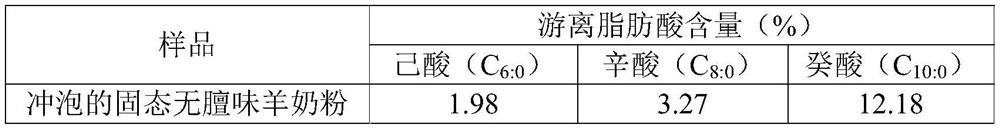

[0061] (4) For the free fatty acid caproic acid (C 6:0 ), cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com