Method for removing mutton odor

A technology for removing mutton and mutton, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as ineffective effects, reducing the intensity of mutton odor, and increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

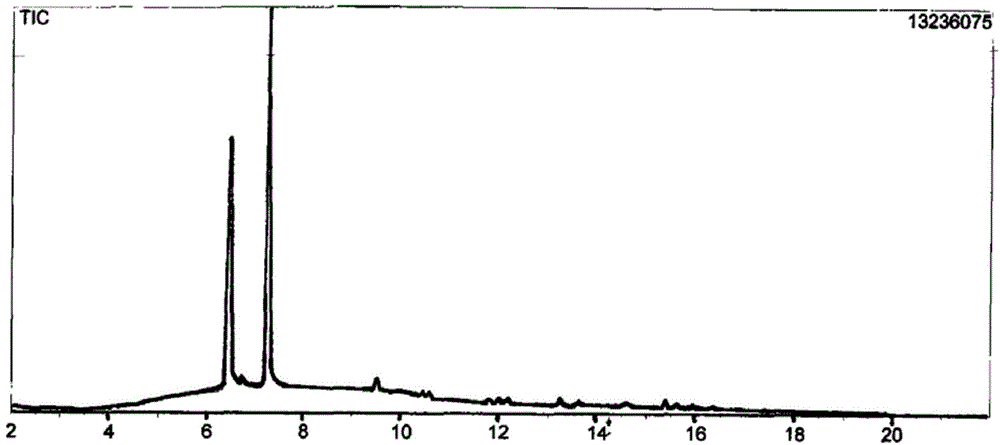

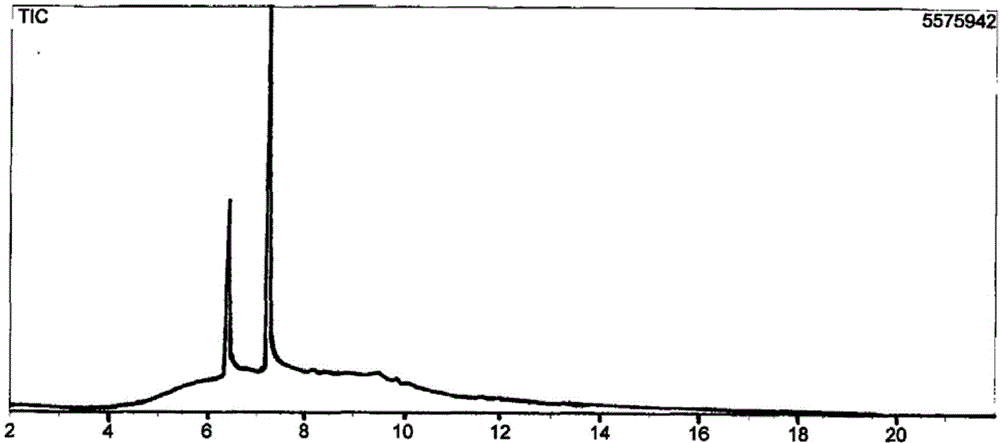

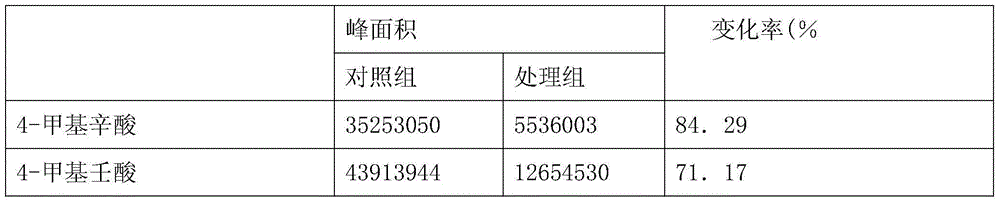

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific examples, the present invention is further described: in the present embodiment, first select Lactobacillus plantarum CICC6002 and Lactobacillus fermentum CICC 6233 (these two kinds of lactic acid bacteria are purchased from China Industrial Microculture Collection Center) as starting strains, the described According to the components, the MRS medium includes 10.0g of casein peptone, 10.0g of beef extract, 5.0g of yeast powder, 5.0g of glucose, 5.0g of sodium acetate, 2.0g of diamine citrate, 1.0g of Tween80, 2.0g of K2HPO4, MgSO4.7H2O0 .2g, MnSO4.H2O0.05g, CaCO3 20.0g, distilled water 1.0L,

[0031] The concentrations of methyl octanoic acid and 4-methyl nonanoic acid in the base reached 1000 mg before inoculation, and finally two pure cultures of enriched Lactobacillus plantarum and Lactobacillus fermentum were obtained after separation.

[0032] Rinse the mutton with sterile water, weigh after treatment, use two enriched cultured la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com