Multi-cavity microsphere with gradient structure and preparation method

A gradient structure and multi-chamber technology, which is applied in the fields of biology and chemical technology, can solve the problems of limited size and load capacity, and the inability to effectively control the number of chambers. promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a magnetic adsorption inner chamber and a gradient multi-chamber coated with crystalline macromolecules, the specific steps are as follows:

[0031] (1) Use a sucrose molecule with a relative molecular mass of 3000-5000 and 4-6 moles of hydroxyl per mole and a molecular weight of 5000-10000 with -CH per mole 2 -Polycaprolactone molecules with a mass ratio of 70-80% are synthesized to obtain amphiphilic block copolymers with a molecular weight of 8000-15000; and then self-assembled to obtain spherical micelles;

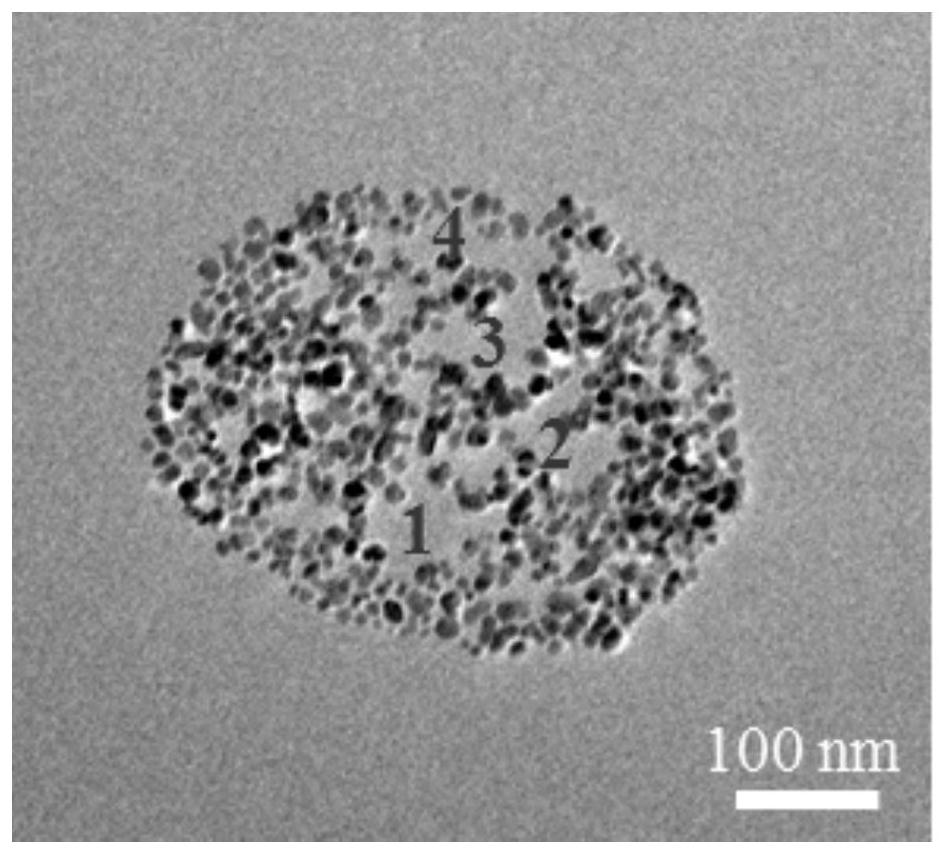

[0032] (2) Then spherical micelles and citric acid-modified ferroferric oxide magnetic nanoparticles are added into a volatile solvent in a molar ratio of 1:2, specifically tetrahydrofuran, mixed evenly, dropped into distilled water, and stirred until uniform Mix; mechanically stir at a constant speed of 80rpm under a 40°C water bath, add a certain amount of acetic acid solution to adjust the pH value to 4.0 after 2 hours, and adjust the s...

Embodiment 2

[0035] The difference between this example and Example 1 is only that a certain amount of acetic acid solution is added to adjust the pH value to 5.0, and the metastable polymer formed by magnetic attraction has an average of 3 chambers.

Embodiment 3

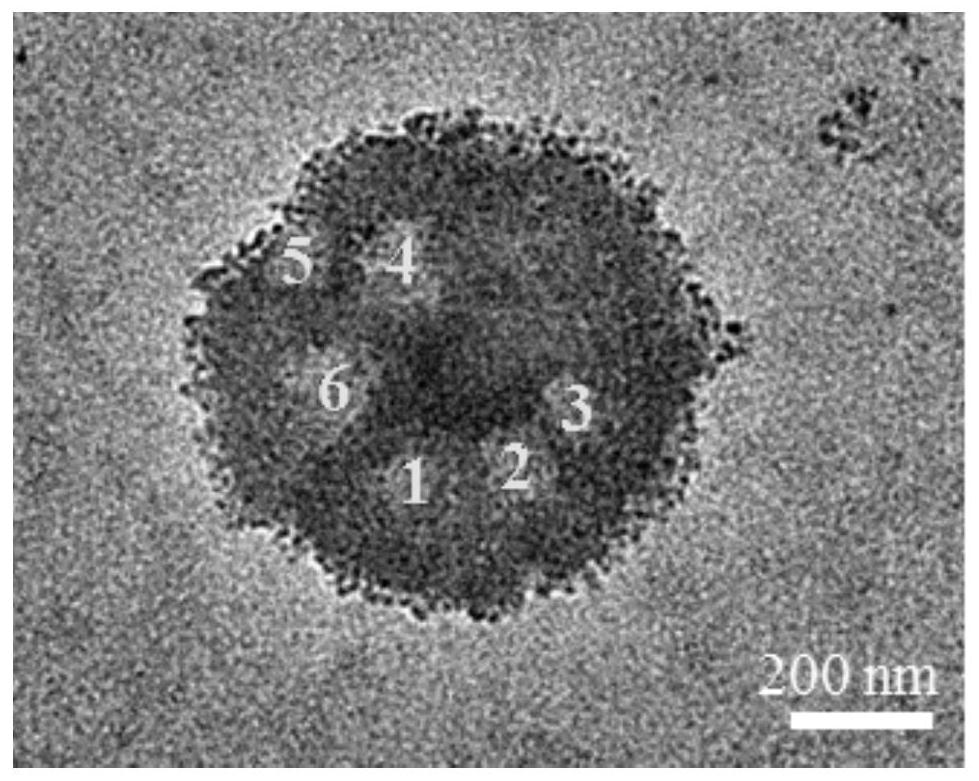

[0037] The difference between this example and Example 1 is only: adding a certain amount of acid solution to adjust the pH value is dilute hydrochloric acid, the adjusted pH value is 4.0, and the metastable polymer formed by magnetic attraction has an average of 6 cavities chamber with an average particle size of 650 nm. The TEM image of its structural characterization is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com