Shield muck recycling modifying process method

A process method and resource utilization technology, which are applied in the field of shield tunneling slag resource utilization, can solve the problem that shield tunneling slag cannot be utilized in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

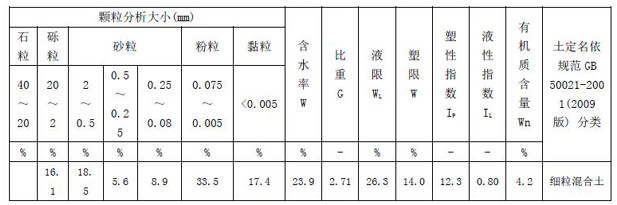

[0032] The shield muck of a subway project, after random sampling of the muck in the collection pit, the average value of its physical and chemical indicators is as follows figure 1 Shown:

[0033] (1) The resource improvement process of the present invention is used for pretreatment and resource improvement to form brick-making raw material soil.

[0034]Since the moisture content of the shield dregs is less than 30%, dehydration and drying treatment is not required. The R215-9 excavator is used to dig out the dregs in the collection pit, and the materials are directly fed into the 210-type soil improvement integrated machine for crushing and mixing pretreatment. Obtain uniform fine-grained dry soil; feed the fine-grain dried soil into the 210-type soil improvement all-in-one machine for resource improvement, and put in powder soil curing agent as the modifier, and the dosage of the modifier is fine-grain dry 5% of the soil mass. The components and contents of the powder so...

Embodiment 2

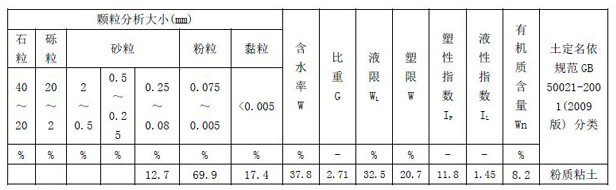

[0041] The shield muck of a subway project, after random sampling of the muck in the collection pit, the average value of its physical and chemical indicators is as follows figure 2 Shown:

[0042] (1) The resource improvement process of the present invention is used to perform dehydration and drying treatment, crushing and mixing pretreatment and resource improvement to form brick-making raw material soil.

[0043] Since the moisture content of the shield slag is greater than 30% and less than 40%, the in-situ dehydration treatment is directly carried out in the collection pit, and block quicklime is used as the dehydrating agent, and the dosage of block quicklime is 4% of the mass of the slag; the quicklime Add it into the soil collection pit, use the R215-9 excavator to carry out the in-situ mixing operation, mix the quicklime and the shield dregs evenly, and then use the rainproof cloth to cover the muck in the soil collection pit, the purpose of the stew The quicklime c...

Embodiment 3

[0055] The shield muck of a subway project, after random sampling of the muck in the collection pit, the average value of its physical and chemical indicators is as follows figure 2 Shown:

[0056] (1) The resource improvement process of the present invention is used to perform dehydration and drying treatment, crushing and mixing pretreatment and resource improvement to form brick-making raw material soil.

[0057] Since the moisture content of the shield slag is greater than 40% and less than 50%, the in-situ dehydration treatment is carried out directly in the soil collection pit, and block quicklime is used as the dehydrating agent, and the dosing ratio of block quicklime is 6% of the mass of the shield slag; Put the quicklime into the collection pit, use the R215-9 excavator to carry out the in-situ mixing operation, mix the quicklime and the shield dregs evenly, and then use the rainproof cloth to cover the muck in the collection pit and stew the material. The purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com