Mechanical slicing device for food processing

A technology of food processing and slicing device, applied in metal processing and other directions, can solve the problems of affecting the integrity of slicing, reducing work efficiency, low slicing efficiency, etc., to reduce the risk of scratches, improve slicing efficiency, and improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

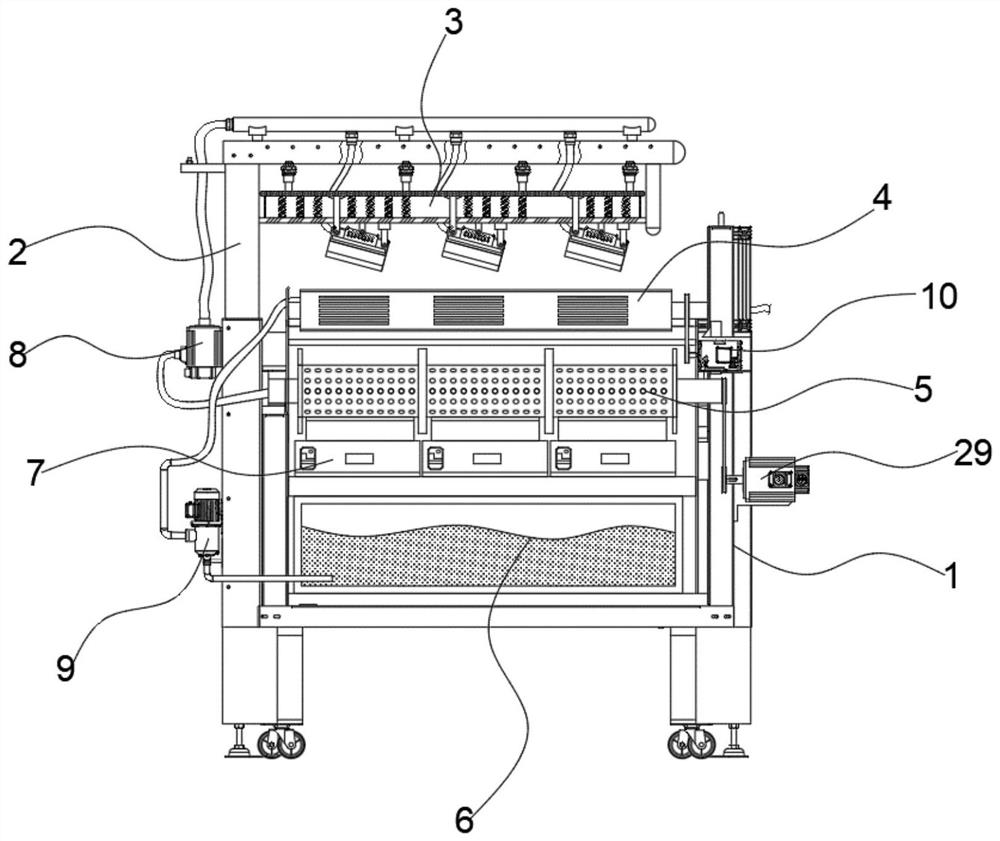

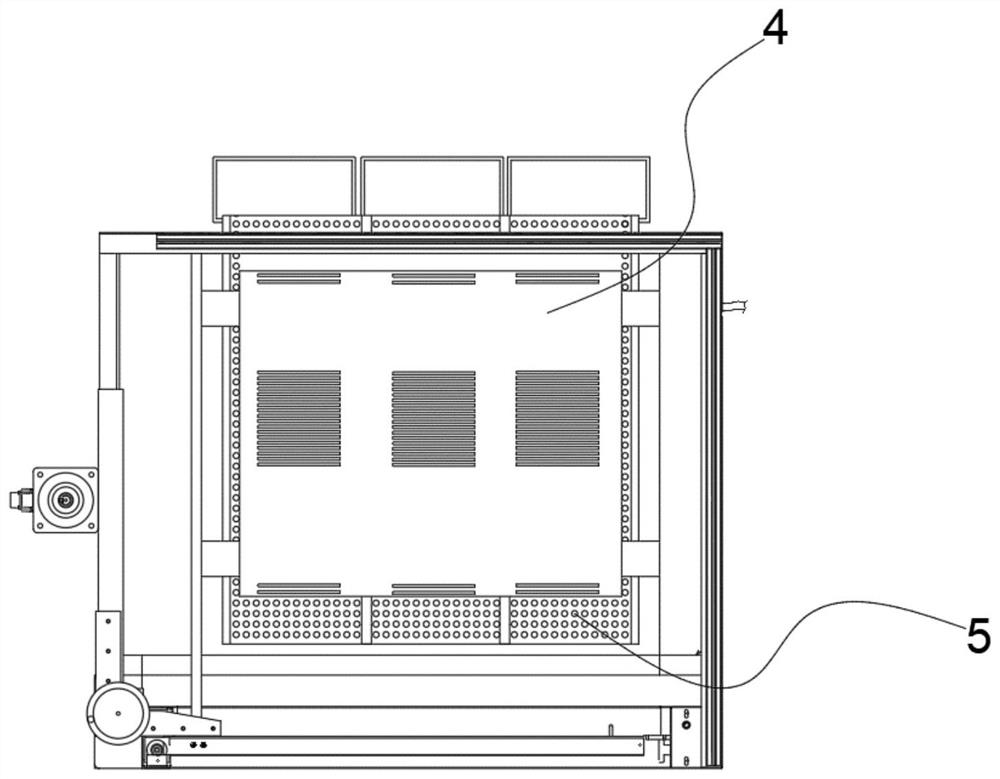

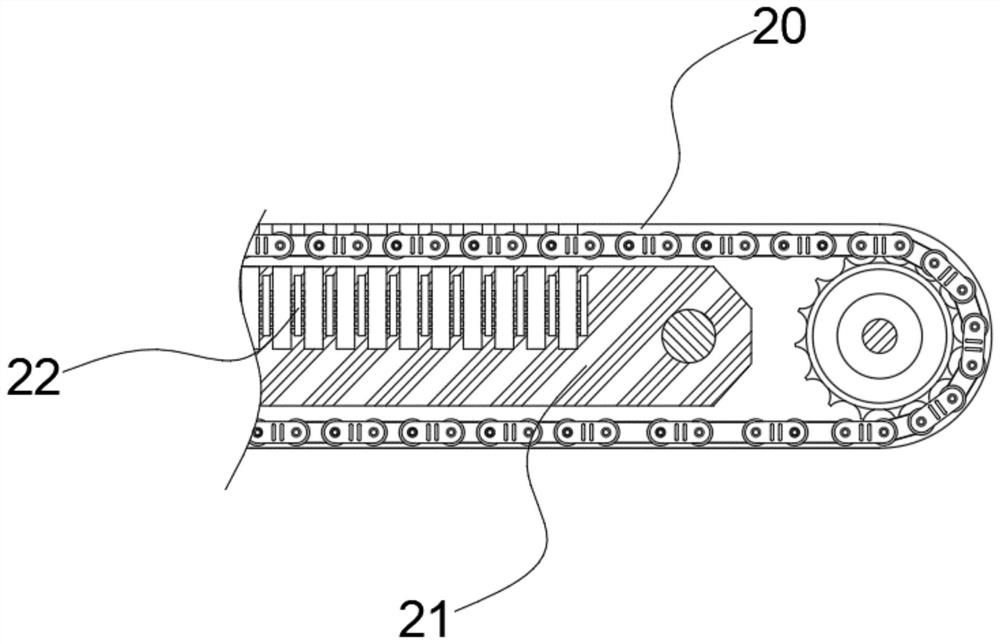

[0041] see figure 1 , figure 2 , in an embodiment of the present invention, a mechanical slicing device for food processing, which includes a frame 1, a slicing assembly 3 and a cleaning assembly 4, wherein the slicing assembly 3 is installed on the cylinder 2 located on the left side of the frame 1 The end of the telescopic shaft is convenient to control the slicing assembly 3 to move up and down; the cleaning assembly 4 is arranged directly below the slicing assembly 3, so as to cooperate with the slicing assembly 3 to complete the slicing process of the food; the cleaning assembly 4 A conveyor belt 5 is provided below for conveying sliced food materials. The conveyor belt 5 is driven by a frequency conversion motor 29 and slowly rotates clockwise at a constant speed; the cleaning assembly 4 is fixed on the frame 1 The air pump 8 on the left side is connected to provide a layer of air compartment for the slice assembly 3 and to dry the slice assembly 3;

[0042] The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com