Hard mica plate adhesive and preparation method thereof

A technology for adhesives and mica boards, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of mica paper waste, reduce the performance of hard mica boards, anti-sticking, etc., and achieve the effect of improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

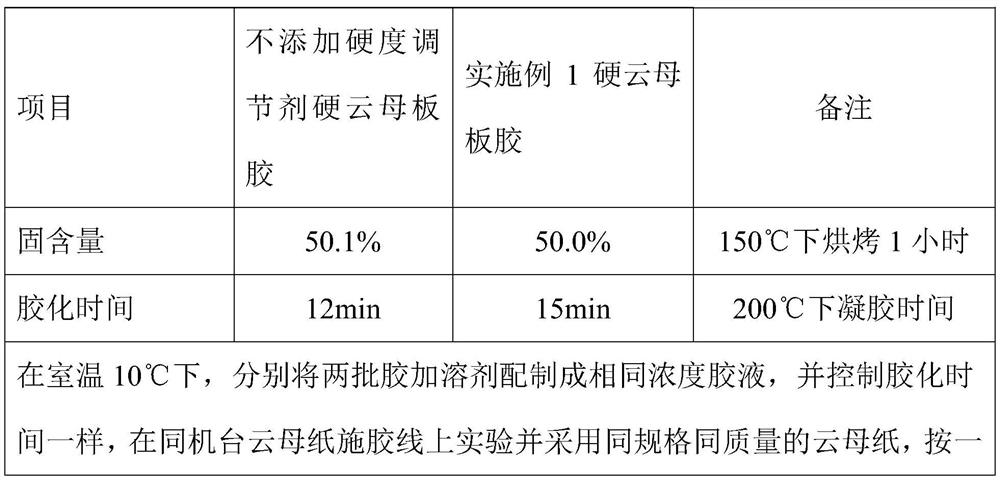

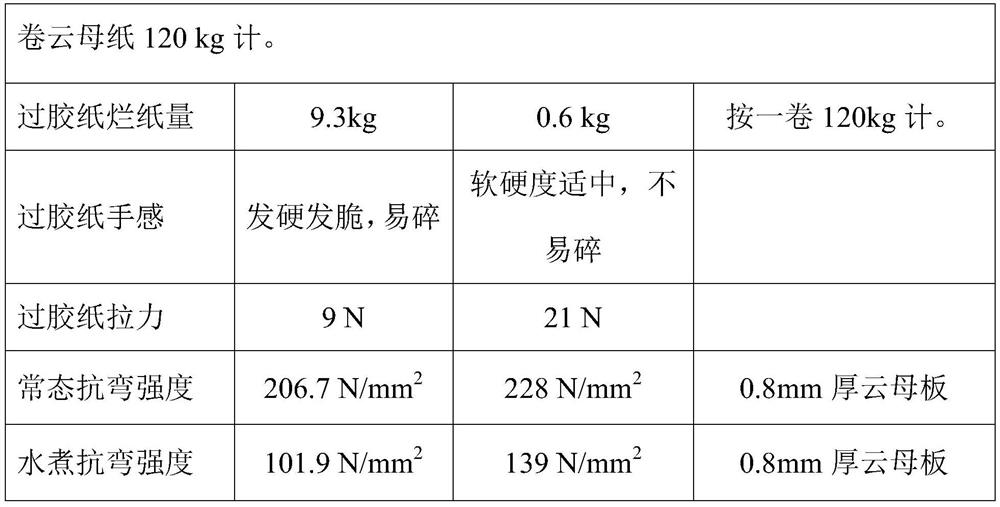

Embodiment 1

[0023] This embodiment provides a hard mica board adhesive, comprising the following raw material components: 70 g of n-butanol, 400 g of toluene, 150 g of monomethyltrichlorosilane, 5 g of dimethyldichlorosilane, and 5 g of trimethylmonochlorosilane 3g, Propyltrichlorosilane 2g.

[0024] The preparation method of above-mentioned hard mica board adhesive is:

[0025] Add 480g of deionized water, 70g of n-butanol, and 280g of toluene into a three-necked flask equipped with a stirrer, a thermometer, and a dropping tube, and turn on the stirrer to stir thoroughly; 150g of silane, 5g of dimethyldichlorosilane, 3g of trimethylchlorosilane, 2g of propyltrichlorosilane, and 60g of toluene were added dropwise at a constant speed at 30°C, and stirred for half an hour after the addition; Move the material to the separatory funnel, let go the lower end of the aqueous solution, add 80°C hot water to wash until neutral, put the material into a three-necked flask equipped with a stirrer, t...

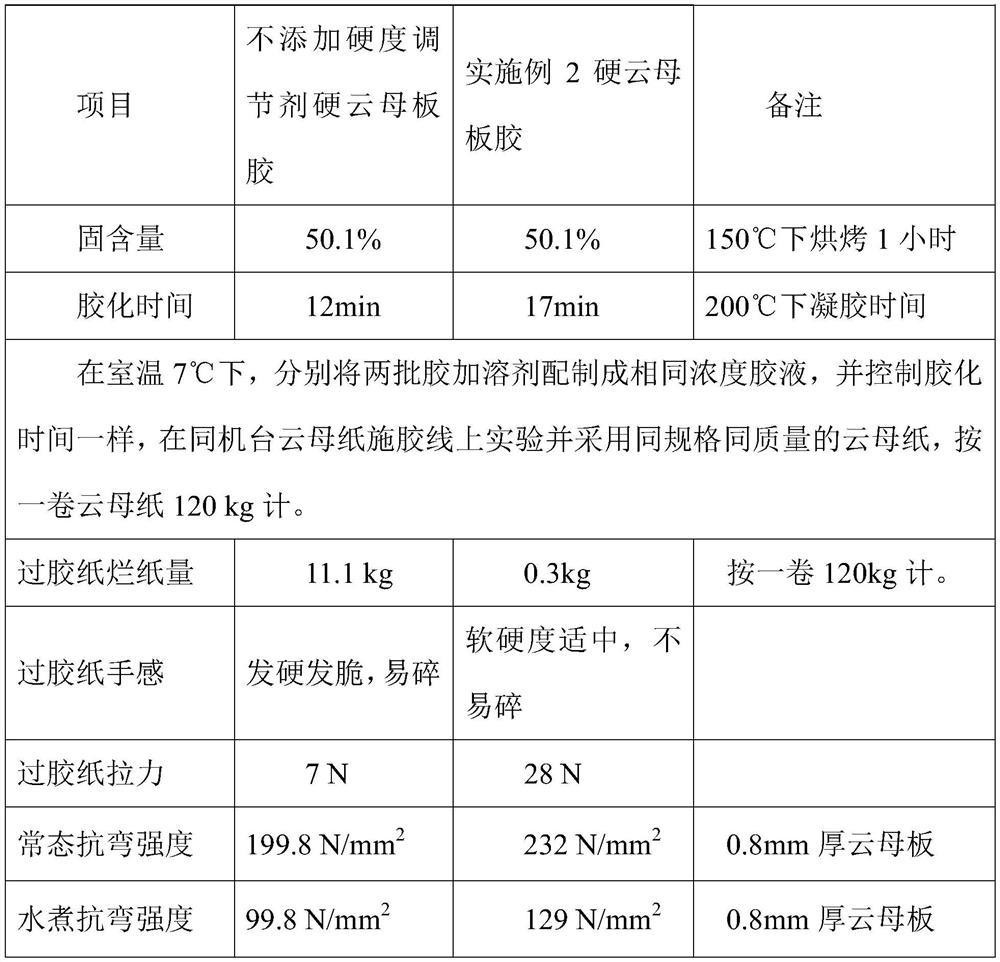

Embodiment 2

[0032] This embodiment provides a hard mica board adhesive, comprising the following raw material components: 60 g of n-butanol, 377 g of toluene, 140 g of monomethyltrichlorosilane, 6 g of dimethyldichlorosilane, and 6 g of trimethylmonochlorosilane 2g, 3g of propyltrichlorosilane.

[0033] The preparation method of above-mentioned hard mica board adhesive is:

[0034] Add 500g of deionized water, 60g of n-butanol, and 250g of toluene into a three-necked flask equipped with a stirrer, a thermometer, and a dropping tube, and turn on the stirrer to stir thoroughly, and add the mixed monomethyl trichloro Silane 140g, dimethyldichlorosilane 6g, trimethylmonochlorosilane 2g, propyltrichlorosilane 3g, toluene 70g. Perform uniform dropwise addition at 30°C, stir for half an hour after the dropwise addition, transfer the material in the three-neck flask to the separatory funnel, let go the lower end of the aqueous solution, add 80°C hot water to wash until neutral, and put the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com