Offshore wind power single-pile composite winged gravity type foundation and construction method thereof

A gravity-based foundation and offshore wind power technology, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problem of unreasonable solutions to basic structure research, increase the cost of marine transportation and installation, and increase the use of steel for single-pile foundations. Quantity and other problems, to achieve the effect of improving positioning problems, less construction difficulty, and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

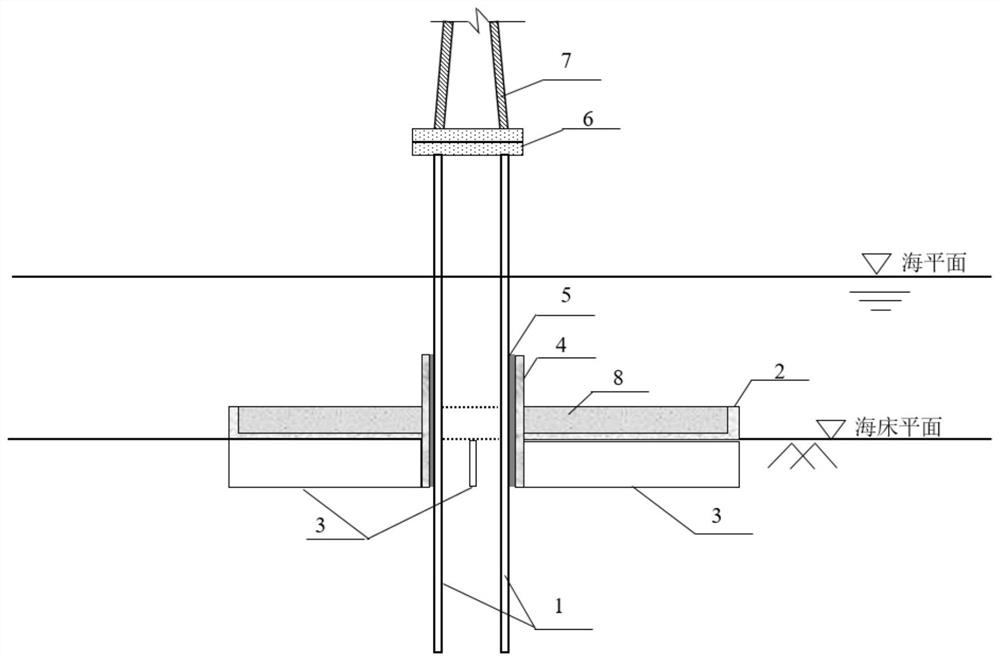

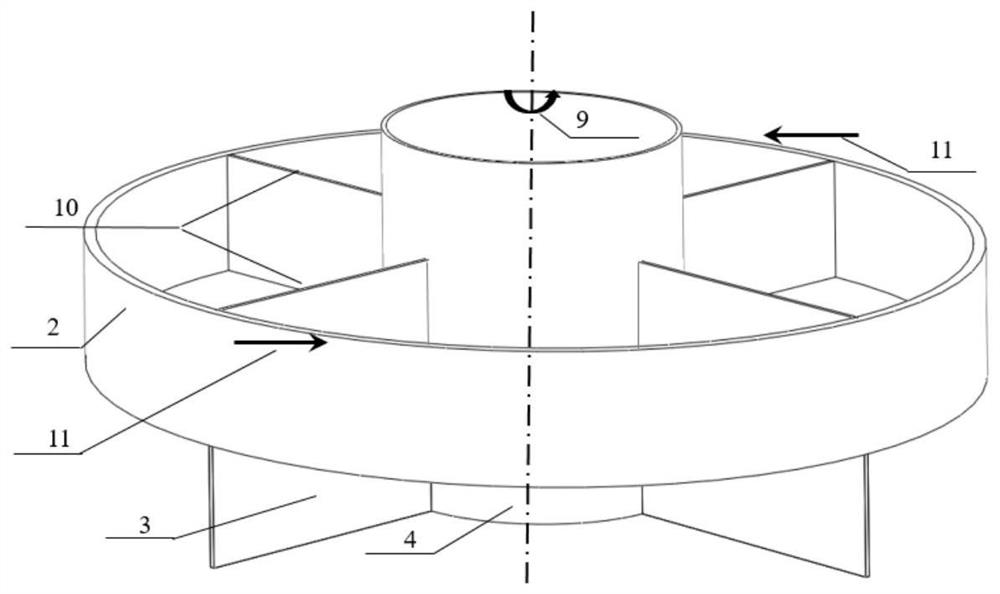

[0029] as attached figure 1 and 2 As shown, an offshore wind power foundation structure composed of a single pile and a gravity foundation with a flange at the bottom, including a single pile, grouting material, a gravity foundation with a flange at the bottom, a flange and a wind turbine Tower.

[0030] The single pile in the example is a steel pipe pile with a diameter of 5m and a pile length of 45m. The gravity-type foundation frame with wing plates is a prefabricated steel structure. There are 4 supporting ribs inside the gravity-type foundation frame. The inside of the frame can be filled with materials such as concrete or gravel to form a gravity type disc. The inner diameter of the casing is 5.16 meters. The inner diameter of the casing is related to the diameter of the steel pipe pile. A certain space must be left for the installation of the steel pipe pile and enough grouting material should be poured in the gap between the two to ensure the overall rigidity of the ...

Embodiment 2

[0035] On the basis of the above-mentioned embodiments, the number of the wing plates can be selected from any number of 3 to 12, which is specifically set according to the comprehensive consideration of the sinking force generated by the gravity disc and the scour capacity of sea waves. The wing plate of the gravity foundation is the key of the entire offshore wind power single pile composite winged gravity foundation. When the wing plate sinks into the seabed with the gravity disc, through the interaction between the wing plate and the shallow soil, It can effectively exert the resistance of the shallow soil, enhance the ability of the gravity disc to resist sliding, and reduce the impact of the erosion by waves. At the same time, the wing plate can effectively limit the displacement of the pile body at the seabed by effectively restricting the displacement of the gravity foundation, and to a certain extent ensure that the wind turbine will not have excessive displacement, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com