Construction technology for retaining wall of complex stratum

A construction technique and technology for complex formations, applied in the direction of reciprocating drilling rigs, drilling equipment and methods, drilling compositions, etc., can solve problems such as insufficient limitations of hole walls in complex formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see Figure 1 to Figure 5 Shown:

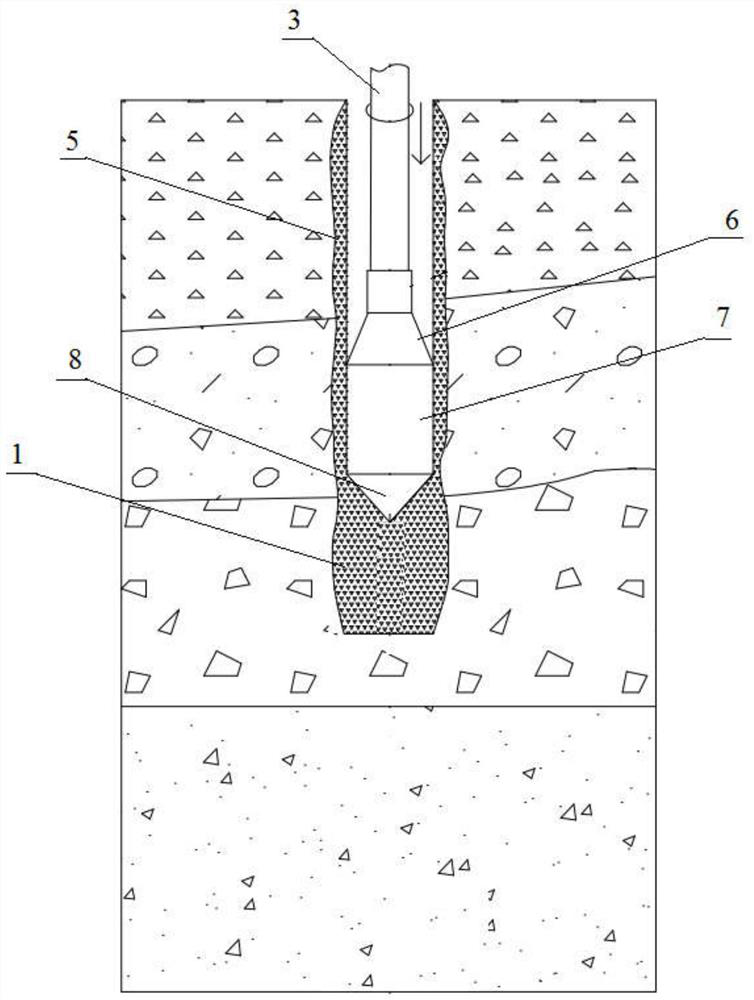

[0025] Step 1. Preparation of loess retaining wall material 1: The natural moisture content of the loess used is 21.5%, the liquid limit is 30.2%, and the plastic limit is 22.1%. After the loess moisture content is modulated between 24%-28%, the mass ratio is loess:lime: Fly ash = 7:1:2 to prepare loess wall protection material 1;

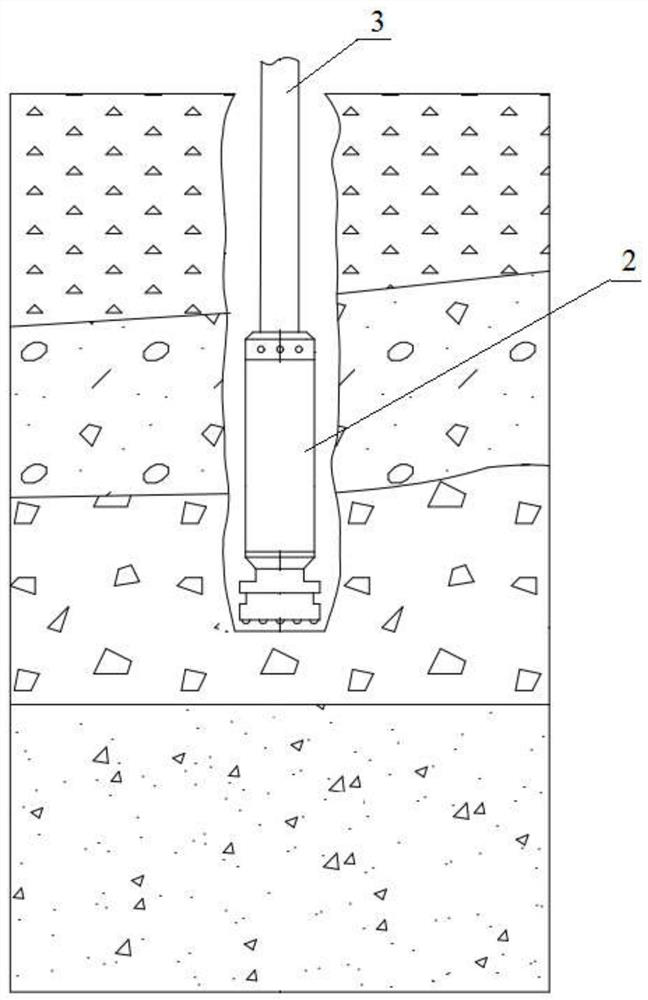

[0026] Step two, see figure 1 , due to the hard and broken strata, the pneumatic down-the-hole hammer 2 drilling technology is used to drill the hole to 3-4m, the diameter of the drill pipe 3 used is Φ89mm, and the diameter of the drill bit is Φ140mm;

[0027] Step 3. Slowly lift the drill pipe 3, take out the pneumatic down-the-hole hammer 2 from the hole, and replace it with a conical drill bit with a diameter of Φ140mm;

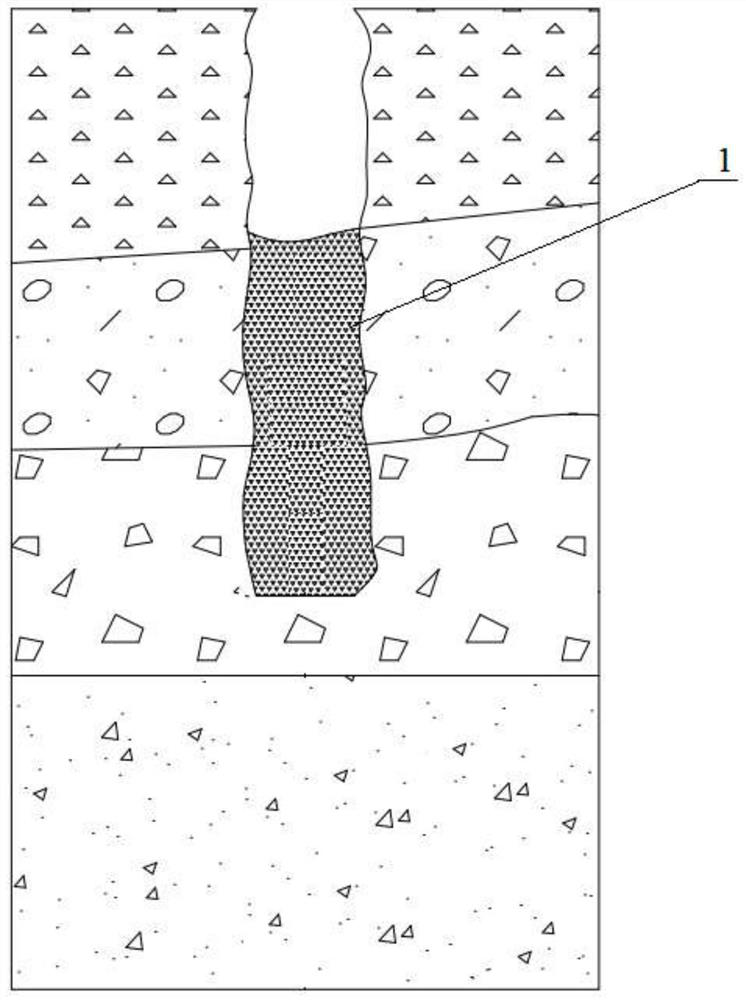

[0028] Step 4, see figure 2 Slowly inject the loess wall protection material 1 into the hole to ensure that the loess wall protection material 1 is filled in the newly drilled hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com