A partial pressure combined production device and method for deep coalbed methane and shallow low-pressure tight gas

A technology for coalbed methane and tight gas, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc. It can solve the problems of small quantity, inability to fracturing different rock layers, and inability to discharge coalbed methane, and achieves an increase in quantity and increase in quantity. The effect of large crack width and number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

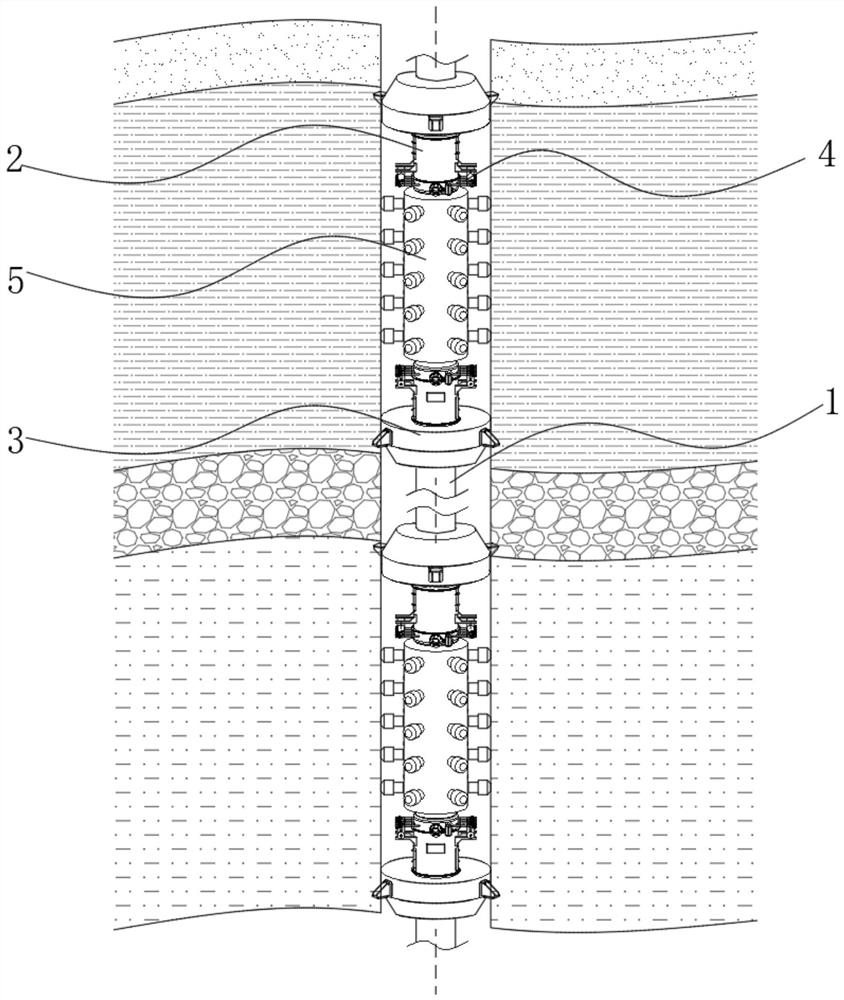

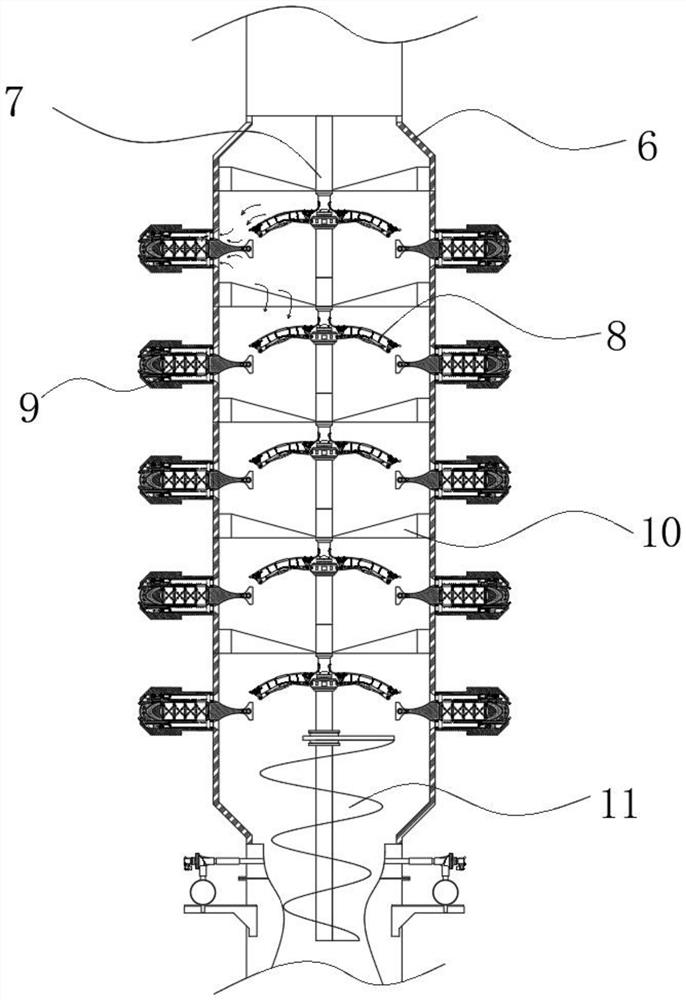

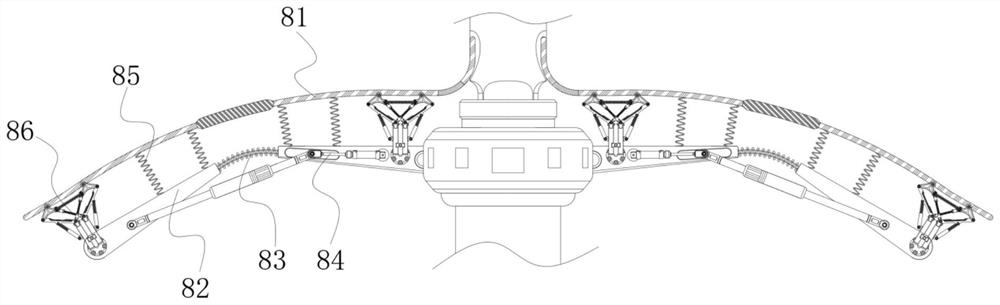

[0034] refer to figure 1 , the present invention provides a technical solution: a deep coalbed gas and shallow low-pressure tight gas partial pressure combined production device, which includes a fracturing pipe 1, a connecting shaft shell 2, a sealing expansion element 3, a pressure monitor 4 and a combined production Device 5, the fracturing tube 1 is a multi-segment spliced structure, the adjacent end of the fracturing tube 1 is installed with a sealing expansion element 3, and the outer circular surface of the sealing expansion element 3 is equipped with a connecting shaft shell 2. A pressure monitor 4 is installed on the side ring surface of the connecting shaft shell 2, and a joint mining device 5 is installed between the adjacent connecting shaft shells 2, and the combined mining device 5 performs fracturing on the rock formation where it is located, and The sealing expansion element 3 and the pressure monitor 4 respectively seal and pressure detect the space layer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com