Energy-saving and consumption-reducing cable conductor and production method thereof

A cable conductor and conductor structure technology, applied in the field of power cables, can solve problems such as deformation and increase in conductor resistance, and achieve the effects of tight conductor structure, lower power consumption, lower product application quality problems and after-sales service costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

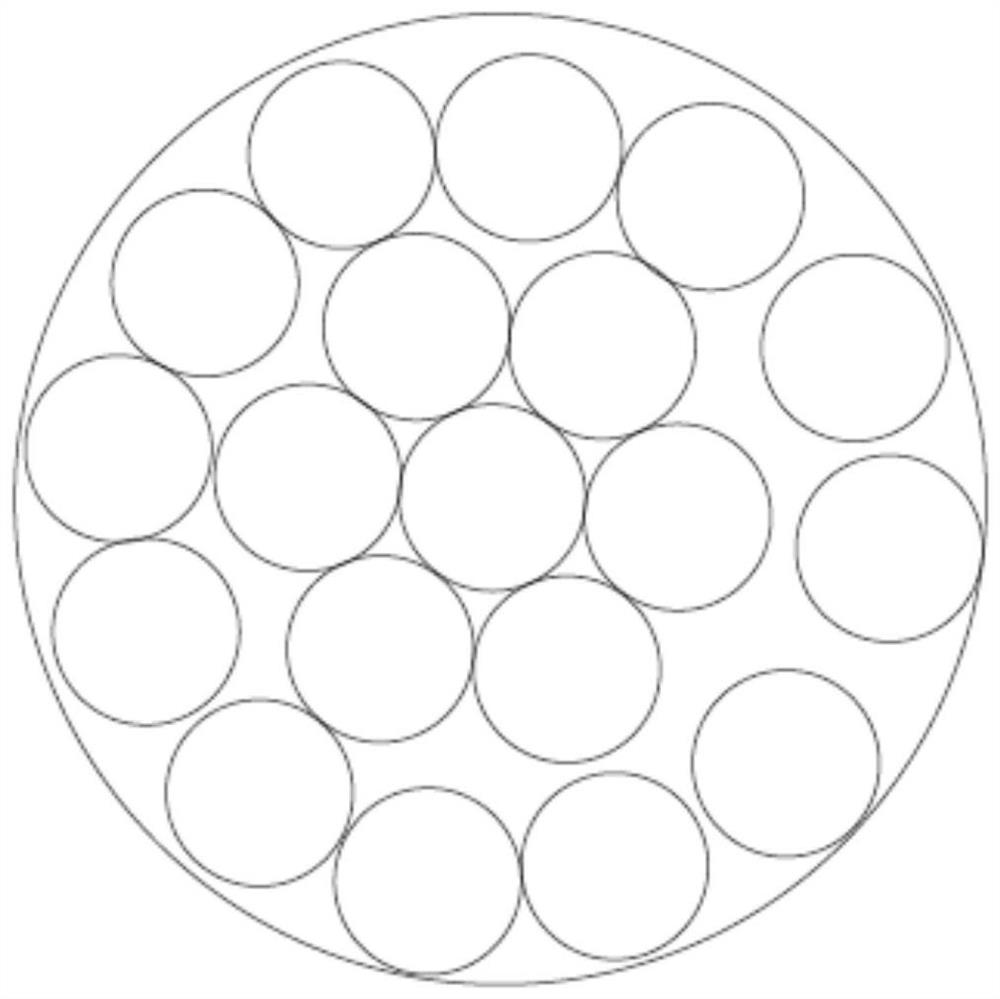

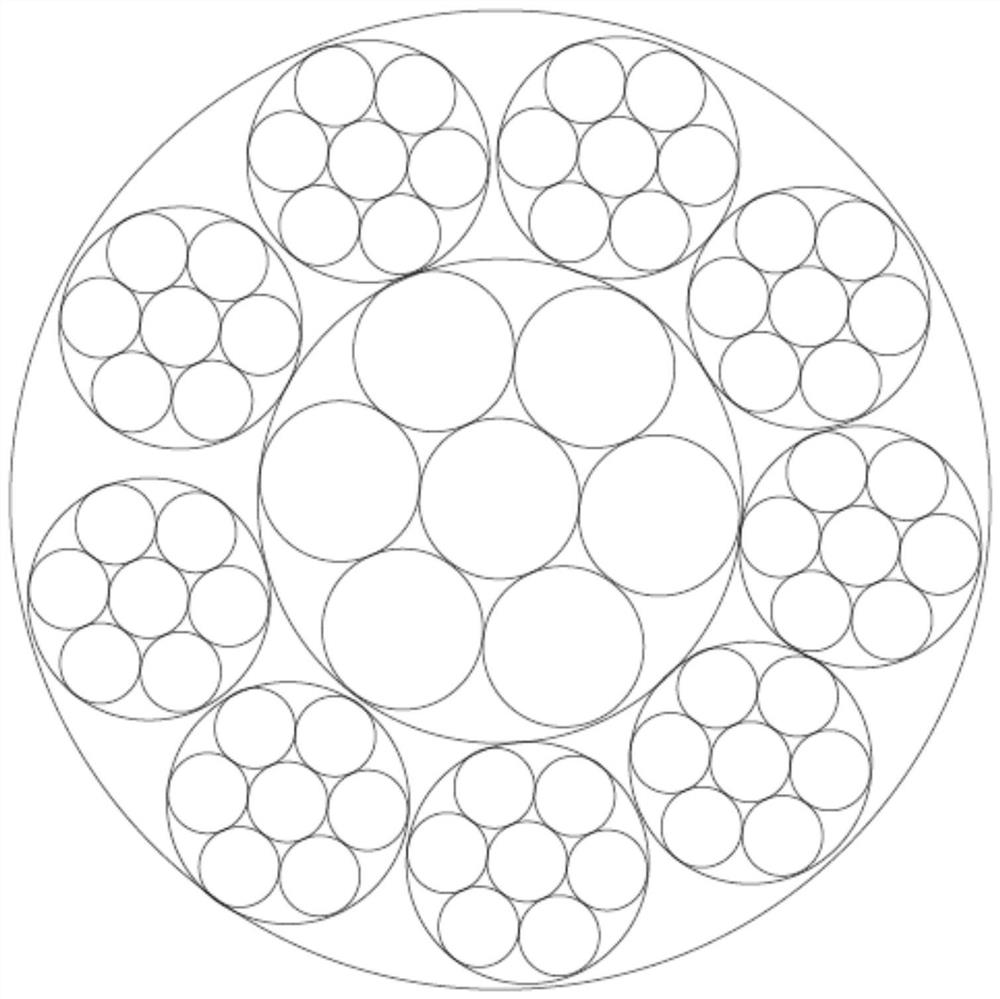

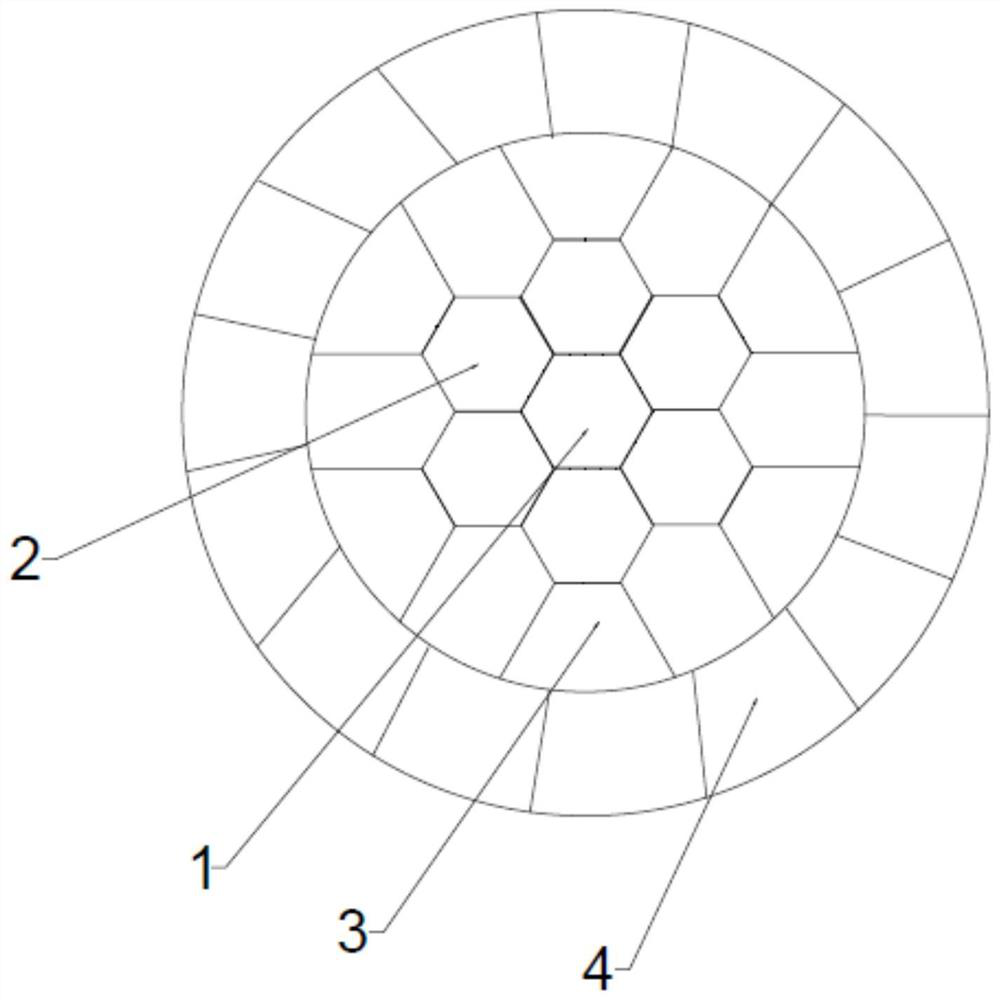

[0017] Such as image 3 As shown, the cable conductor cross section 300mm of the present embodiment is an example, including 34 copper or copper alloy shaped wire conductors, forming a cable conductor with an outer diameter of 19.5mm; the selected copper and copper alloy shaped wire surface should not have wrinkles, Cracks, burrs, inclusions and other defects that are harmful to use, single wires are allowed to be welded, but the distance between two adjacent solder points should not be less than 300mm, the welding must be firm, and the joints must be smoothed and rounded; the cable conductors of this embodiment It contains four layers of conductor structure from inside to outside, which are central layer conductor structure 1, first layer conductor structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com