Can lid for resin metal composite containers, which is formed of resin laminated steel sheet, can bottom for resin metal composite containers, which is formed of resin laminated steel sheet, and resin metal composite container

A metal composite and resin layer technology is applied in the fields of resin-laminated steel plate lids for resin-metal composite containers, resin-laminated steel plates for resin-metal composite containers, and resin-metal composite containers. Uneven adhesion, low container strength, etc., to achieve the effects of excellent manufacturability and surface quality, high hemming strength, and excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

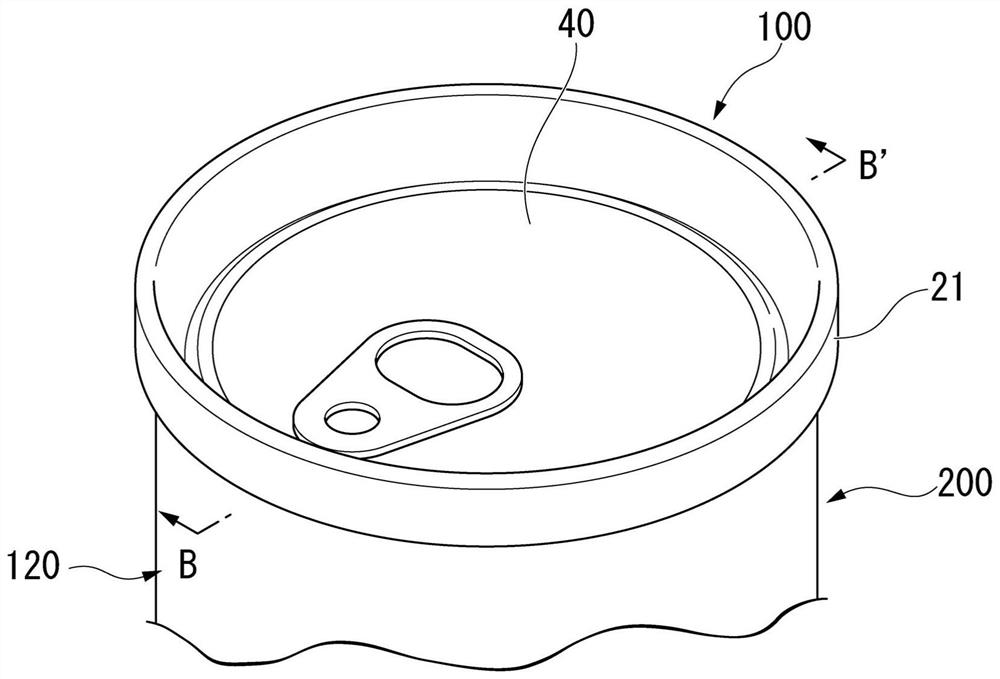

[0171] The resin-laminated steel plate can lid and can bottom for resin-metal composite containers according to the present invention will be specifically described with reference to examples.

[0172] However, the conditions in the examples are examples employed to confirm the practicability and effects of the present invention, and the present invention is not limited to the following examples. As long as the purpose of the present invention is achieved without departing from the gist of the present invention, it can also be implemented by appropriately changing within a range suitable for the gist. Therefore, the present invention can adopt various conditions, which are included in the technical characteristics of the present invention.

[0173] In Examples and Comparative Examples, the content of (4) steel plate, which is the constituent material of the resin laminated steel plate used as the material for the resin laminated steel plate can lid and the bottom of the resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com