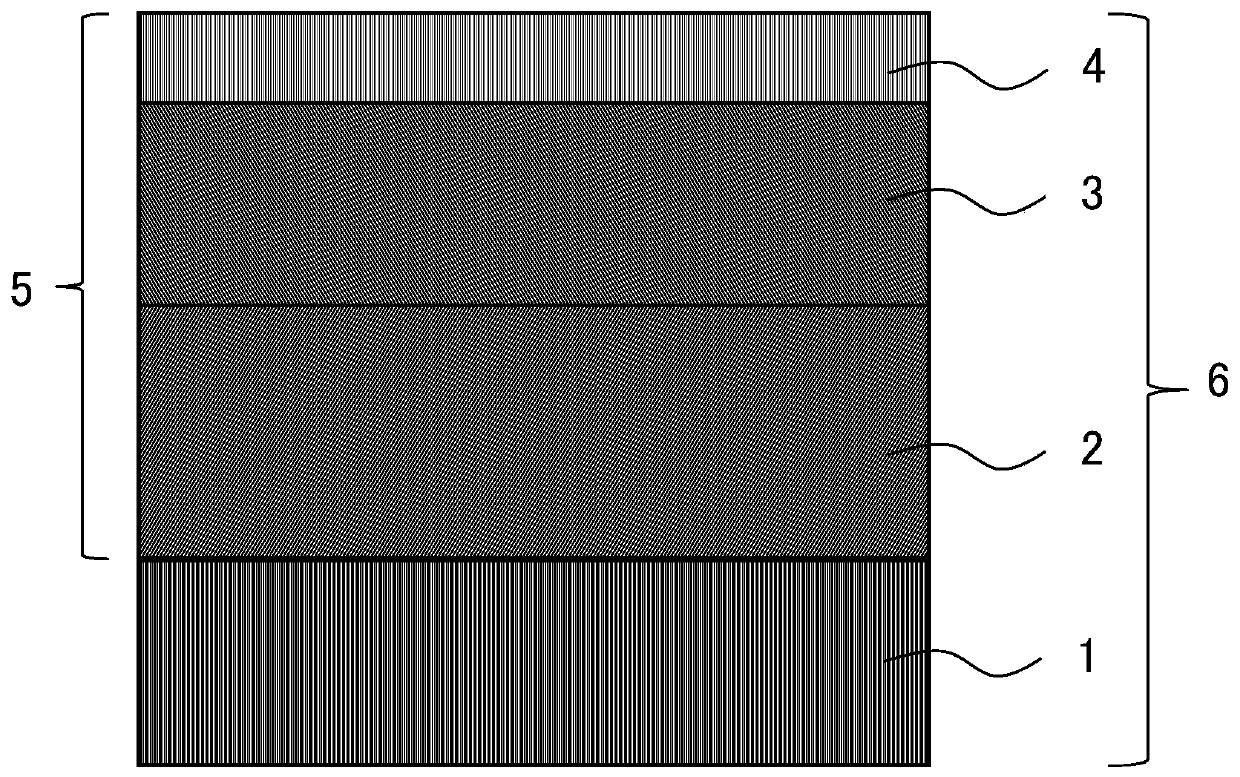

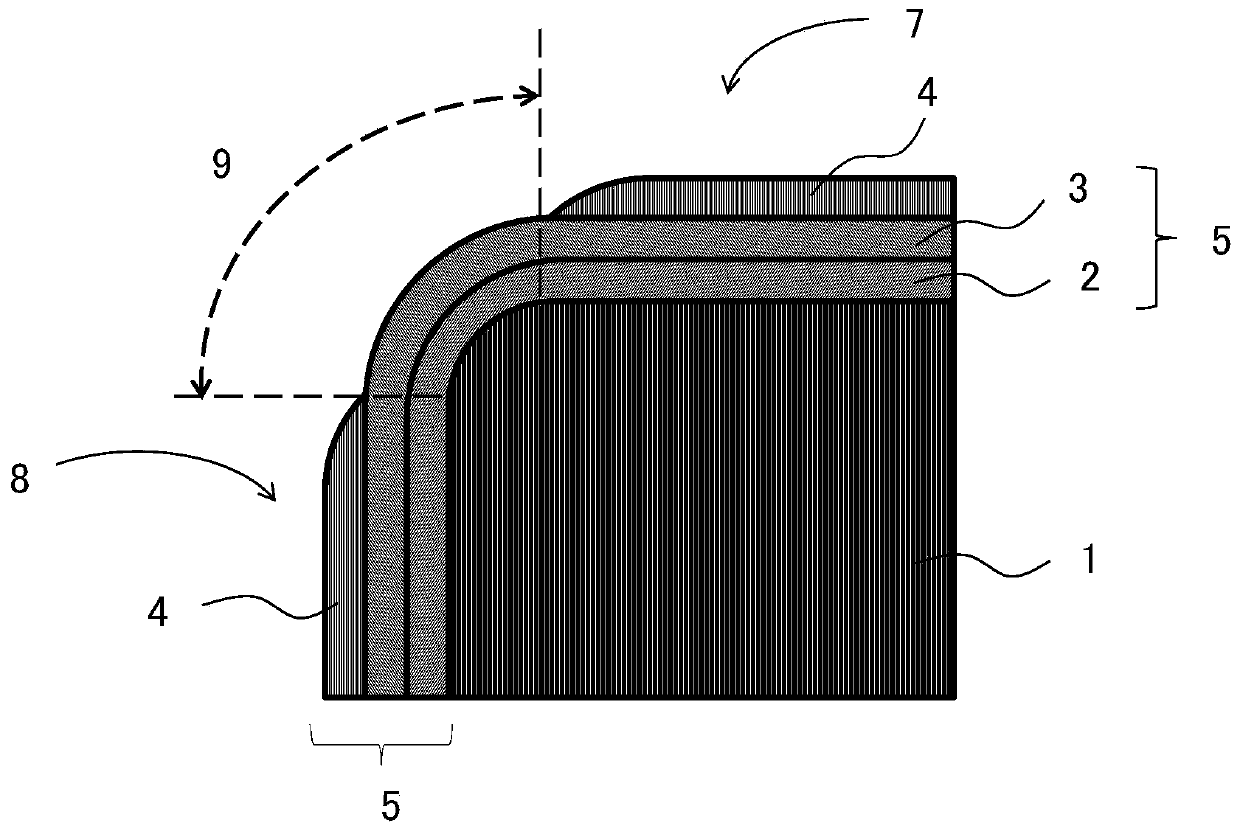

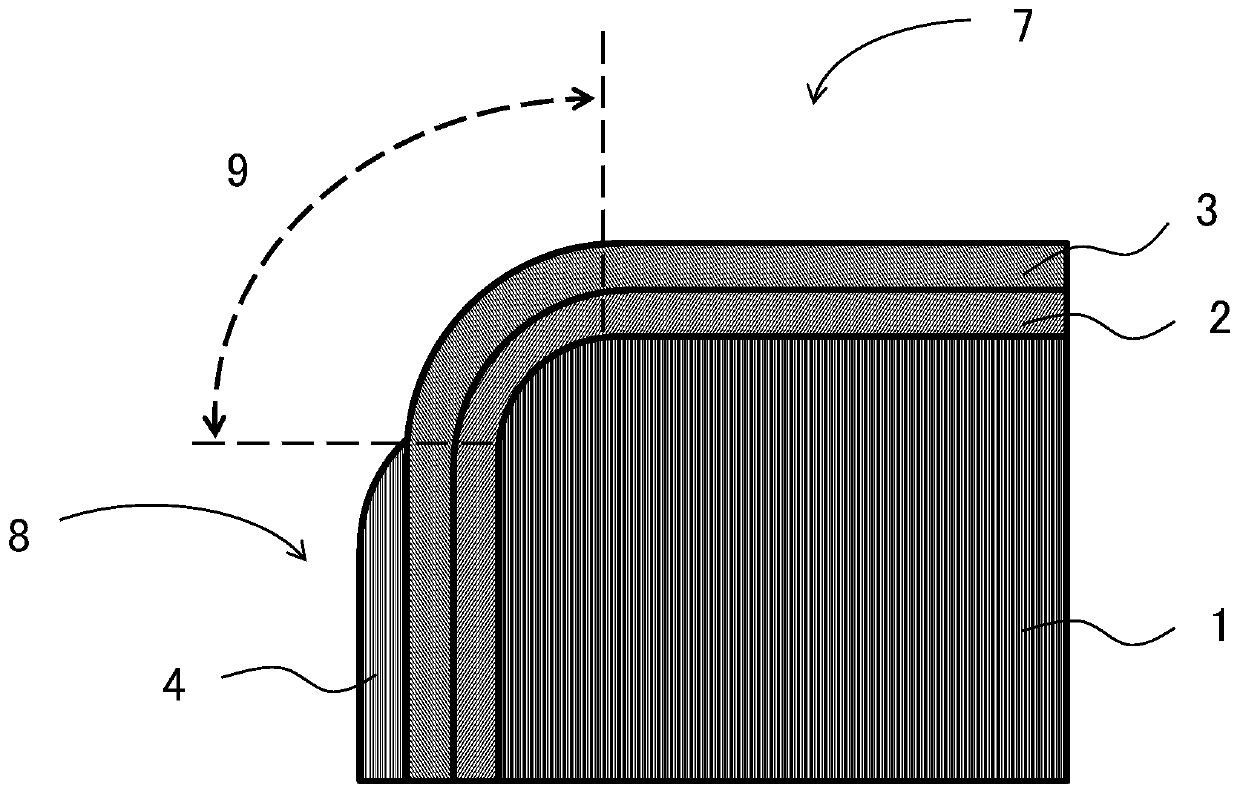

Coated cutting tool

A cutting tool and coating technology, used in the manufacture of tools, workpieces, drill accessories, etc., can solve problems such as shortening tool life, and achieve the effect of excellent machined surface quality and long tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0138] Hereinafter, the present invention will be described in more detail with examples, but the present invention is not limited to these examples.

[0139] [Substrate]

[0140] For the following substrates, after rounding the ridge line of the cutter head with a SiC brush, the surface of the substrate was cleaned and used.

[0141] [Substrate 1]

[0142] Shape: CNMG120412

[0143] Material: Cemented carbide (84.4WC-10.8Co-1.9TiC-0.2TiN-2.4NbC-0.3ZrC (above mass%))

[0144] [Substrate 2]

[0145] Shape: CNMG120412

[0146] Material: Hard alloy (93.5WC-6.1Co-0.4Cr 3 C 2 (The above is mass %))

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com