Packaging film, film bag, and method for manufacturing same

A packaging and packaging technology, applied in packaging, wrapping paper, household packaging, etc., can solve the problems of adhesion or dissolution, difficulty in efficiently manufacturing film bags, burning or caking of film bags, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

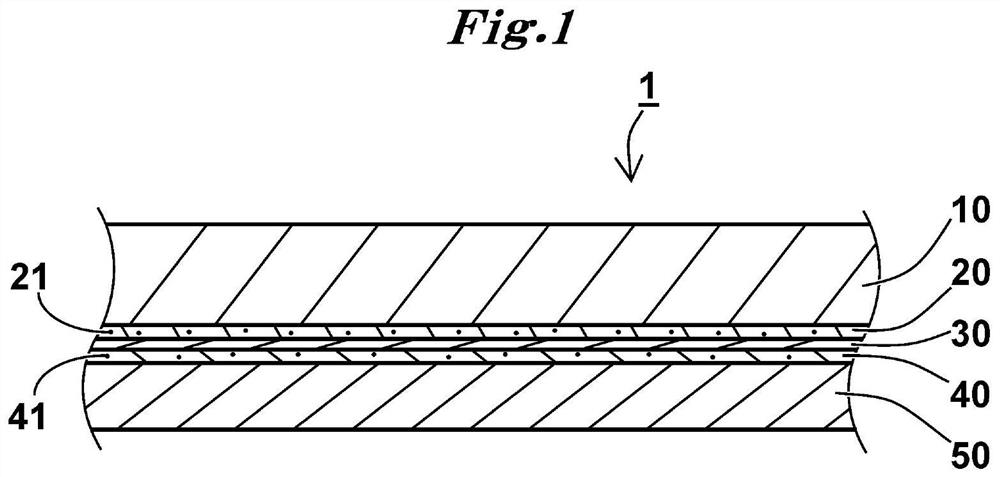

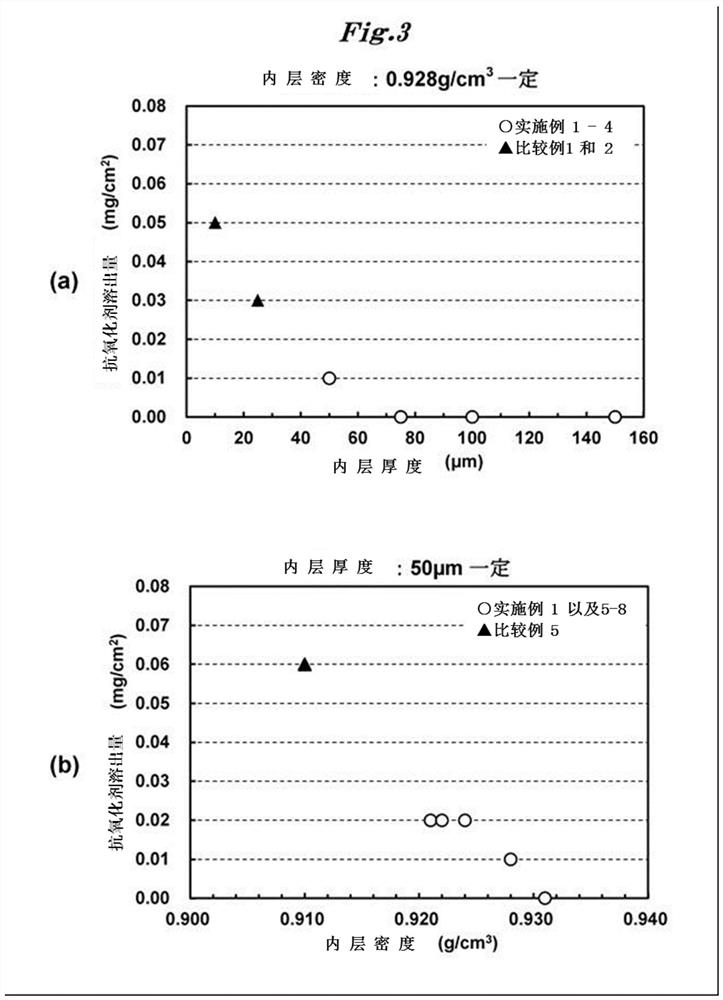

[0063] Resin material for inner layer and resin material for outer layer: LLDPE1 (density 0.930g / cm 3 ) and LDPE1 (density 0.921g / cm 3 ) were mixed at a mass ratio of “LLDPE1:LDPE1=80:20” to prepare a resin material for an inner layer and a resin material for an outer layer that do not contain exudation components.

[0064] Resin material for the first adhesive layer and the second adhesive layer: maleic acid-modified LLDPE (containing 1000 ppm of phenolic antioxidant) was used.

[0065] Resin material for gas barrier layer: Ethylene-vinyl alcohol copolymer resin was used.

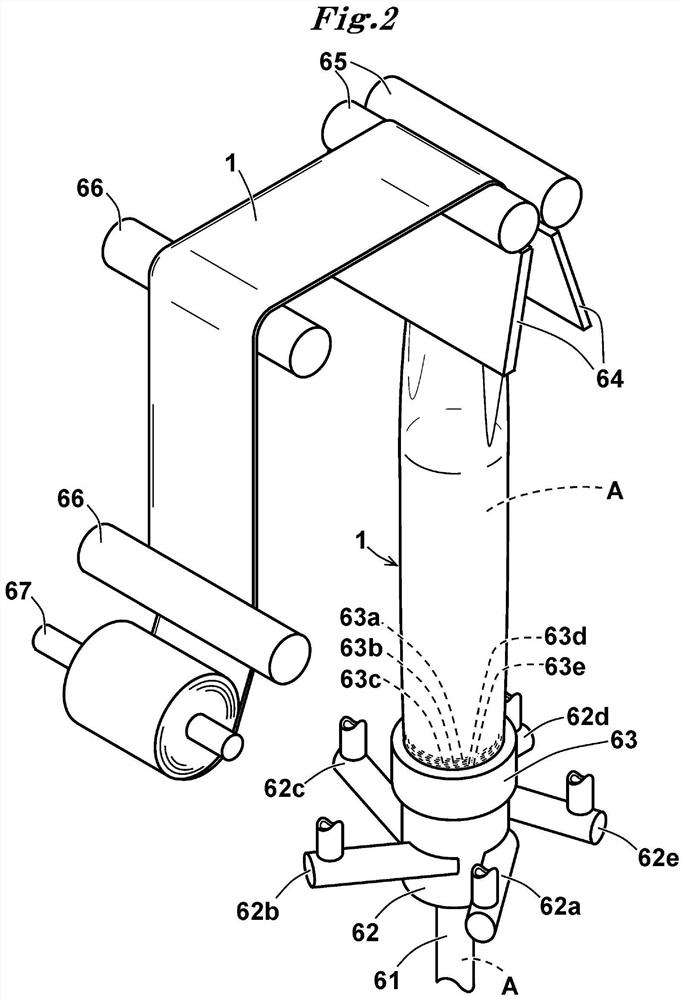

[0066] exist figure 2 In the first to fifth extruders 62a to 62e of the shown multilayer air-cooled blow molding machine, the resin material for the inner layer, the resin material for the first adhesive layer, the resin material for the gas barrier layer, and the second resin material are respectively added. The resin material for the adhesive layer and the resin material for the outer layer are melte...

Embodiment 2~4

[0069] In order to make the thickness of the inner layer 10 a desired value, except that the extrusion amount of the resin material for the inner layer was changed, the packaging films of Examples 2 to 4 and the films made from them were manufactured in the same manner as in Example 1. into film bags. Table 1 shows the composition, density and thickness of the packaging films of Examples 2-4.

Embodiment 5

[0112] Resin material for inner layer and resin material for outer layer: LLDPE2 (density 0.920g / cm 3 ) and LDPE2 (density 0.928g / cm 3 ) were mixed at a mass ratio of “LLDPE2:LDPE2=90:10” to prepare a resin material for an inner layer and a resin material for an outer layer that do not contain exudation components.

[0113] Resin material for the first adhesive layer and the second adhesive layer, and resin material for the gas barrier layer: The same materials as in Example 1 were used.

[0114] Except having used the above-mentioned resin material, it operated similarly to Example 1, the film for packaging of Example 5, and the film bag made from it were manufactured. Table 2 shows the composition, density and thickness of the packaging film of Example 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com