Nitrogen-carbon doped cobalt-based bimetallic catalyst, preparation method thereof and preparation method of 2, 5-dimethyl furandicarboxylate

A technology of dimethyl furandicarboxylate and bimetallic catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficulty in amplification, difficulty in amplification and preparation, and achieve a simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

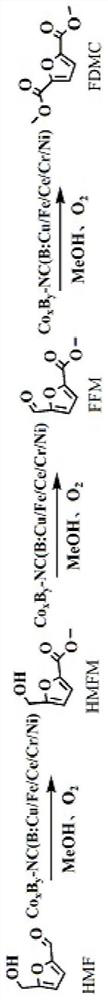

Method used

Image

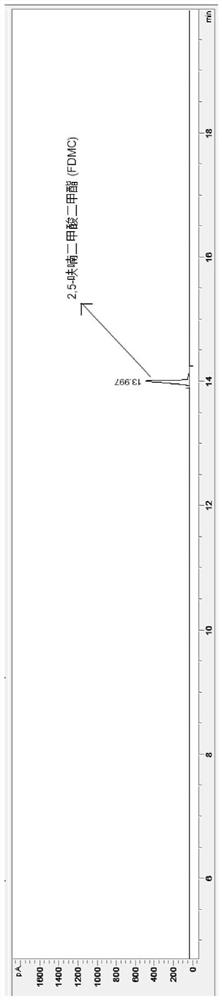

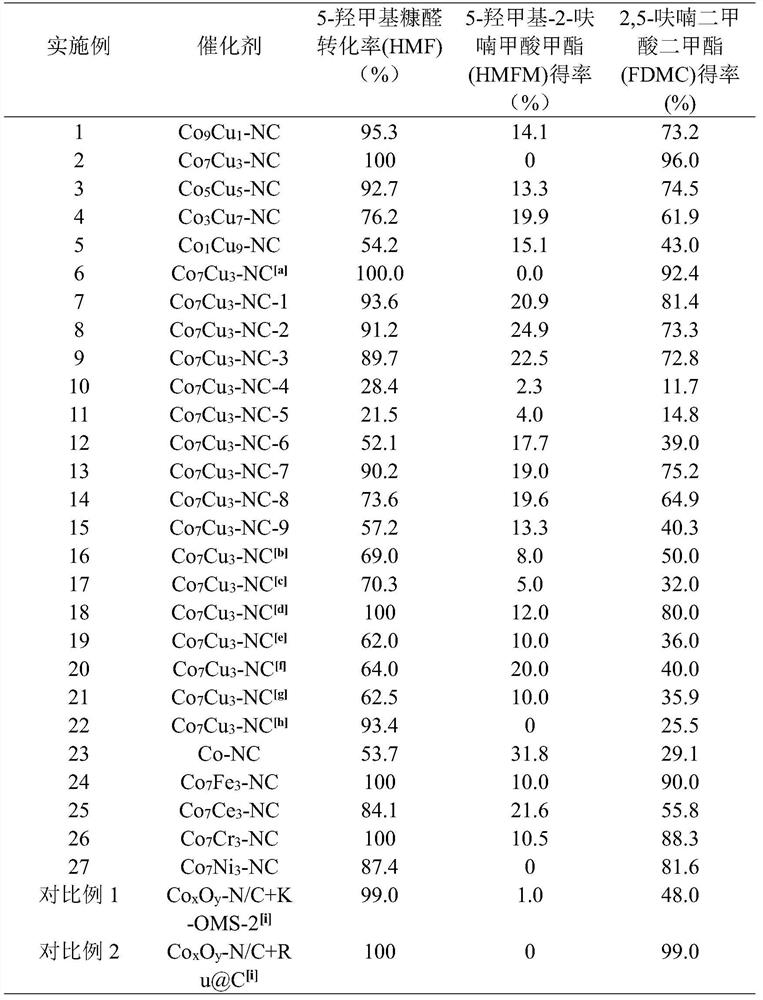

Examples

Embodiment 1-22

[0031] Embodiment 1-22 (nitrogen-carbon doped cobalt-based bimetallic catalyst Co X B Y -NC catalyst, x, y represent its molar ratio;)

[0032]1. Mix and dissolve 2.5047g dicyandiamide, 0.0912g cobalt nitrate hexahydrate, 0.0090g copper nitrate trihydrate and 15.0716ml water in a 50ml beaker, then add 2.2ml formaldehyde dropwise, mix and stir overnight at 105°C and remove Moisture, the solid obtained after drying is ground into powder, and then calcined at 900°C for 2 hours under nitrogen to obtain Co 9 Cu 1 -NC catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com