A kind of superhard cbn ceramic grinding wheel and preparation method thereof

A ceramic grinding wheel and superhard technology, applied in the field of grinding wheels, can solve the problems of poor molding density stability of superhard CBN ceramic grinding wheels, low grinding wheel yield, etc., to reduce the possibility of change, increase yield, and improve density stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

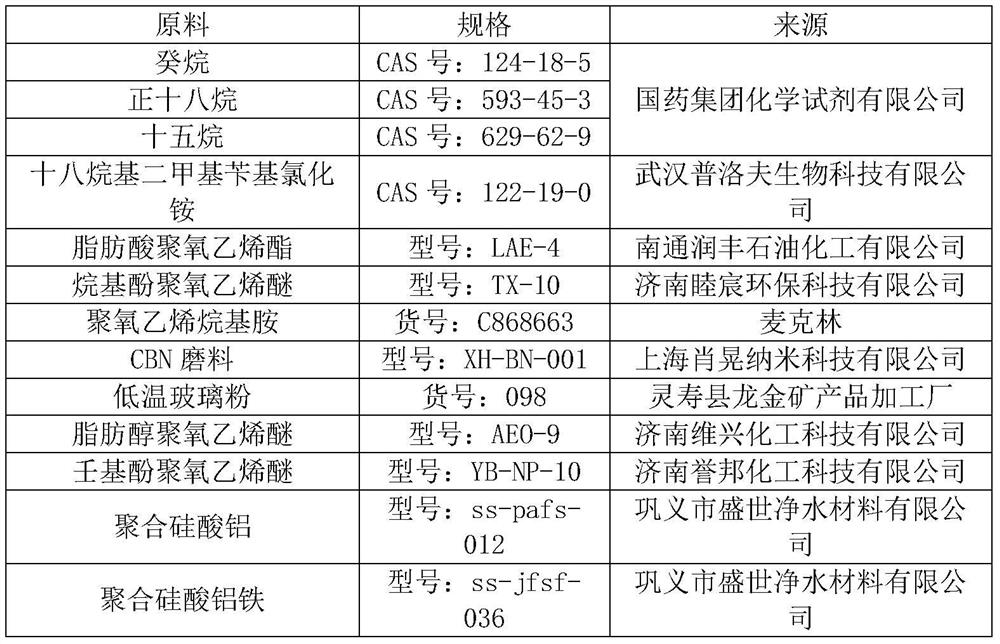

Method used

Image

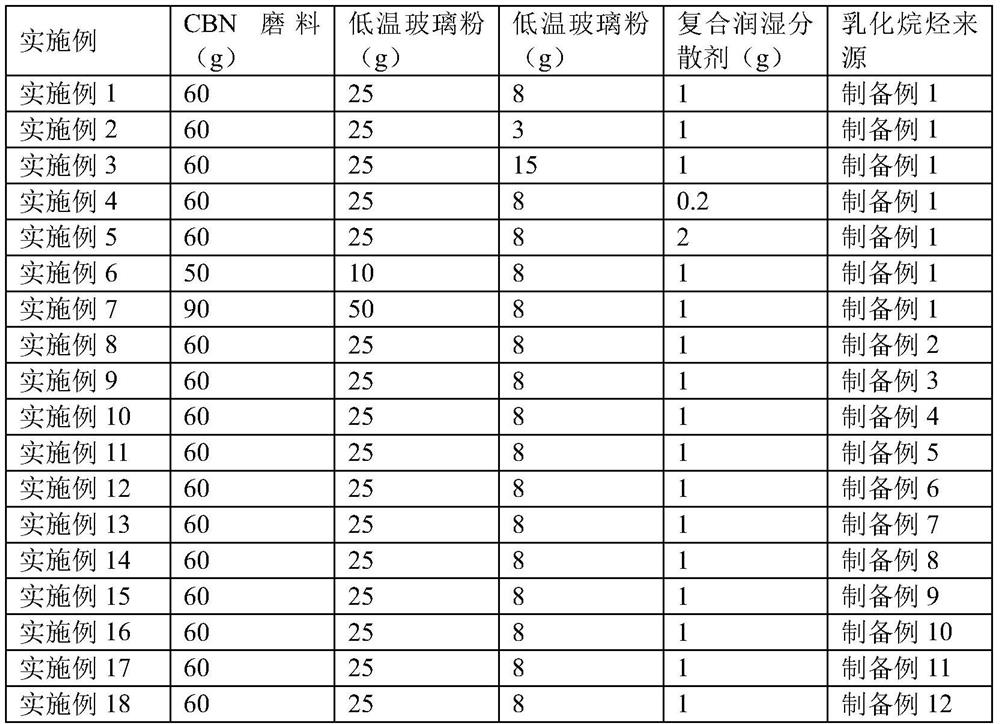

Examples

preparation example 1

[0035] An emulsified alkane, the preparation method is: after mixing 20g of alkane with 20g of water, add 4g of surfactant dropwise while stirring, and raise the temperature to 70°C, then stir for 15min under the condition of heat preservation, and naturally cool to 25°C to obtain the emulsified alkane The alkane used is decane, and the surfactant used is octadecyl dimethyl benzyl ammonium chloride.

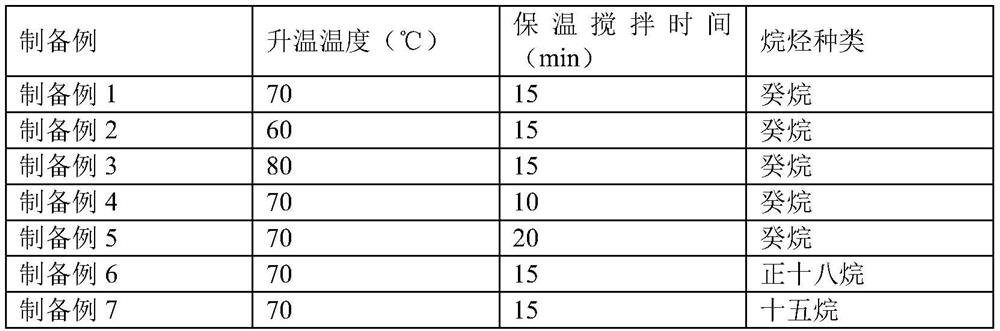

preparation example 2-7

[0037] Preparation Examples 2-7 are all based on Preparation Example 1, and differ from Preparation Example 1 only in that the conditions for preparing emulsified alkanes and the types of alkanes used are different, see Table 2 for details.

[0038] Table 2. Preparation 1-7 emulsified alkane preparation conditions

[0039]

preparation example 8-10

[0041] Preparation Examples 8-10 are all based on Preparation Example 1, and differ from Preparation Example 1 only in that the weight ratios of alkanes, water and surfactants used are different, see Table 3 for details.

[0042] Table 3. The weight ratio of preparation example 8-10 alkane, water and tensio-active agent

[0043] Preparation example Alkanes: Water: Surfactant (weight ratio) Preparation example 8 1:0.5:0.03 Preparation Example 9 1:0.5:0.5 Preparation Example 10 1:0.5:0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com