A Yarn Leading System and Using Method for Enhancing the Antibacterial and Adsorption Functions of Yarn

A yarn and yarn-leading technology, which is applied in the direction of yarn, spinning machine, open-end spinning machine, etc., can solve the problems of structural restrictions, difficulty, difficult yarn, etc., and achieve the effect of stable structure and good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

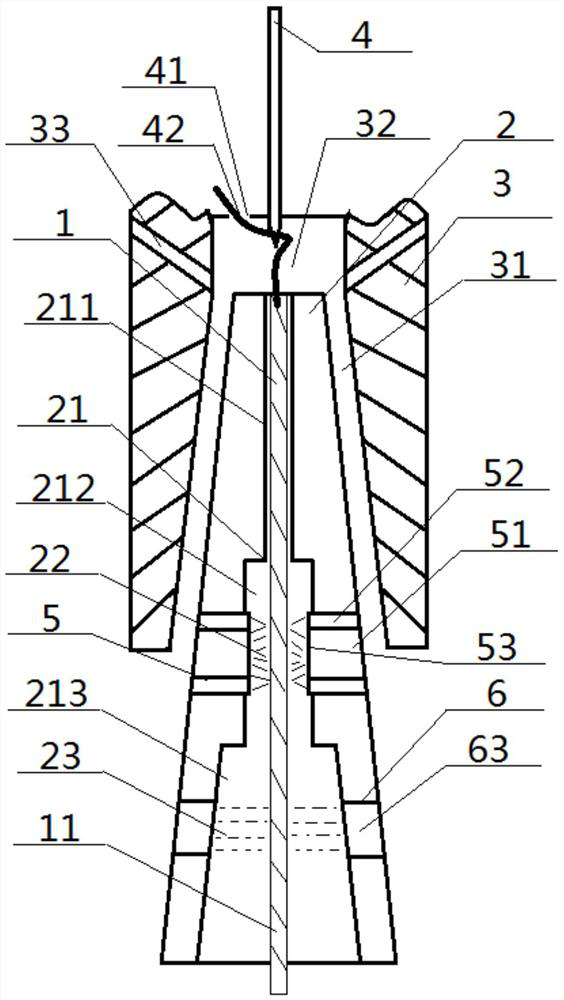

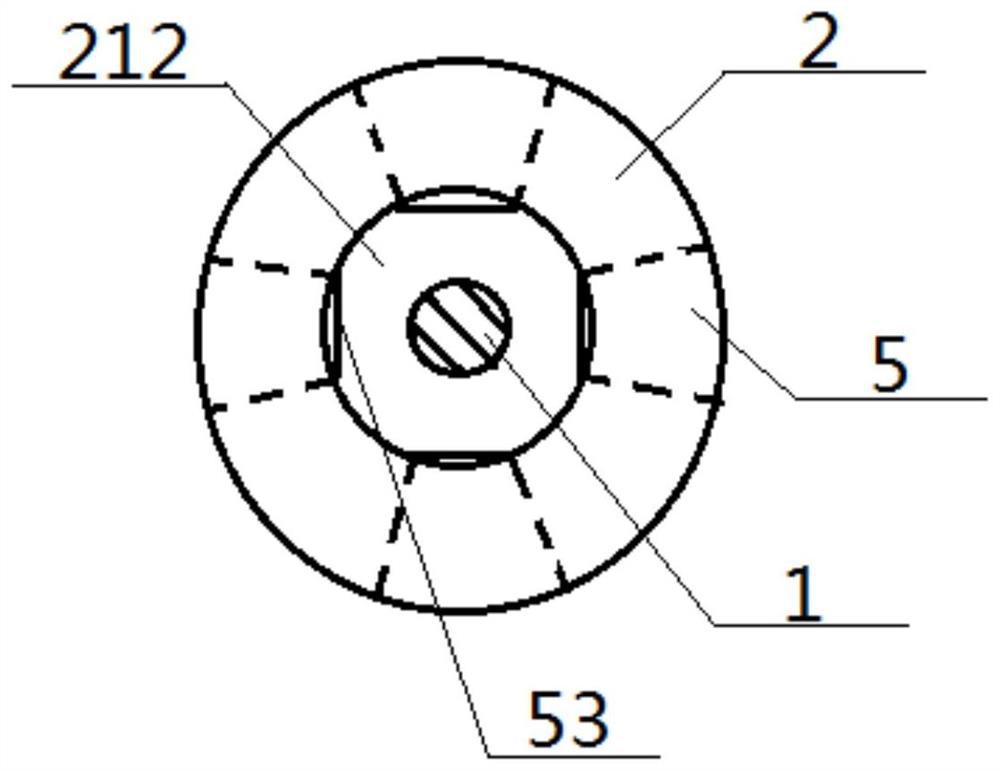

[0055] see figure 1 — Image 6 , a yarn drawing system for enhancing the antibacterial and adsorption function of the yarn, comprising a yarn drawing tube 2 and a vortex tube 3, and an exhaust passage 31 is sandwiched between the side wall of the yarn drawing tube 2 and the inner wall of the vortex tube 3, The middle part of the yarn drawing tube 2 is provided with a yarn drawing channel 21, and the top of the yarn drawing tube 2 is provided with a vortex chamber 32 that communicates with the yarn drawing channel 21. Directly above the chamber 32 is provided a guide needle 4 which is opposite to the yarn guiding channel 21, and a fiber channel 41 is arranged beside the guiding needle 4; the yarn guiding tube 2 is a truncated cone structure, and the yarn guiding channel 21 includes the upper channel 211 for threading, the middle channel 212 for threading, and the lower channel 213 for threading that are communicated in turn, and at least one negative powder spraying device 5 i...

Embodiment 2

[0058] The basic content is the same as that of Example 1, except that:

[0059] The solute of the Yin mist is any one of polypropylene-based hydrochloride, chitosan, polydivinyl propyl dimethyl ammonium chloride, polyethylene imine, polyquaternary ammonium salt, polyvinyl pyridine or any mix;

[0060] The solute of the yang water mist is any one or any mixture of sodium alginate, hyaluronic acid, polyacrylic acid, polystyrene sulfonic acid, polyvinyl sulfonic acid, and polyvinyl phosphoric acid.

Embodiment 3

[0062] The basic content is the same as that of Example 1, except that:

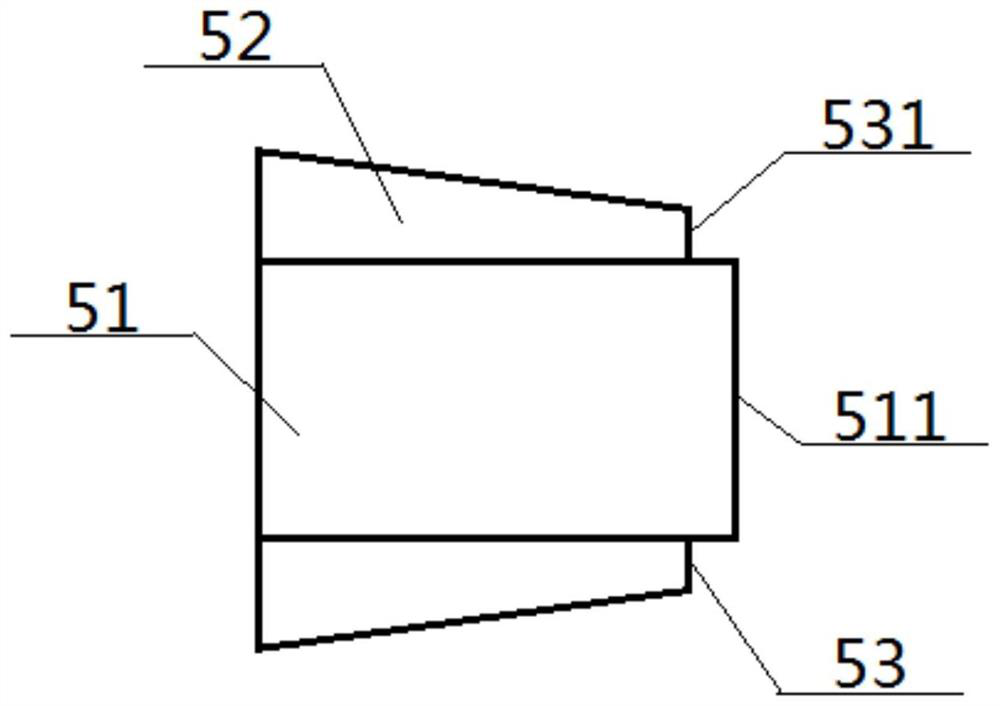

[0063] The powder spray pipe 52 is sleeved on the outside of the Yin liquid spray pipe 51, and the distance between the front end of the powder spray pipe 52 and the channel 212 in the yarn drawing is greater than the distance between the front end of the Yin liquid spray pipe 51 and the channel 212 in the yarn drawing, The side wall of the powder nozzle 52 is gradually increasing along the connecting line between the front end of the powder nozzle 52 and the rear end of the powder nozzle 52; The powder outlet 53 is formed, and the width of the powder outlet 53 is smaller than the radius of the anion liquid nozzle 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com