Automatic screwing-on and screwing-off device for sucker rod

A sucker rod and automatic technology, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of high-altitude objects falling and hitting, time-consuming installation and disassembly, fatigue-prone operation errors, etc., to achieve convenient operation and speed up the workover process , the effect of reducing the risk of personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

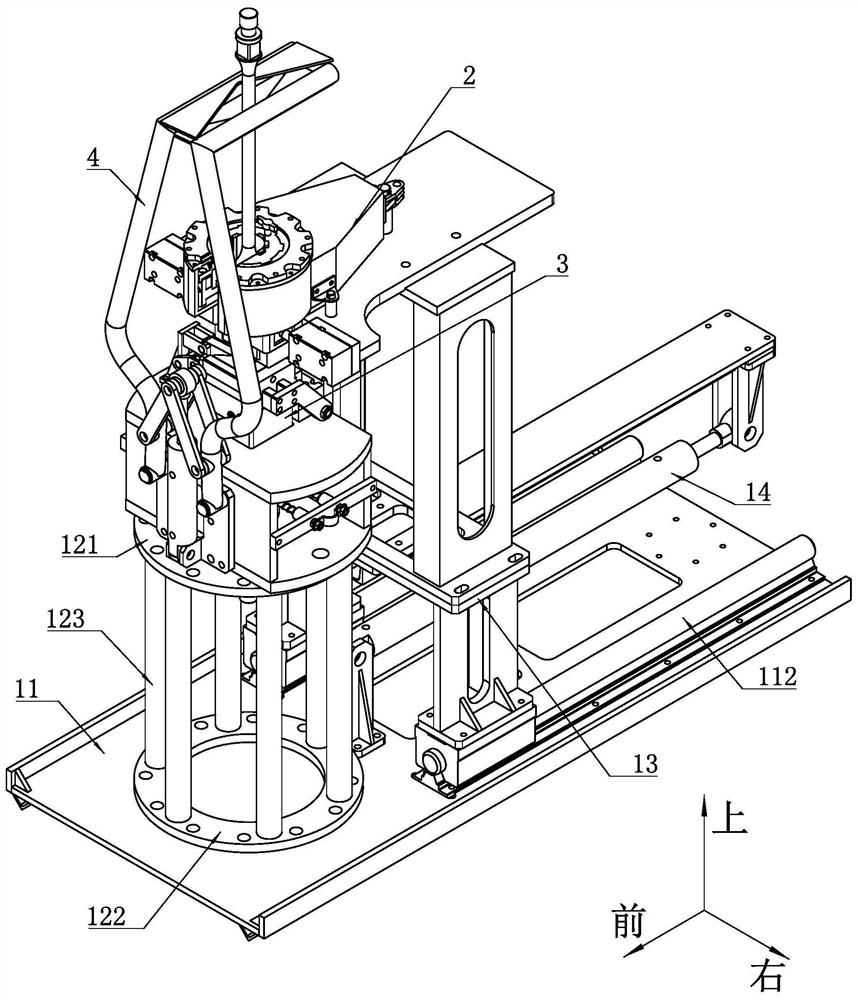

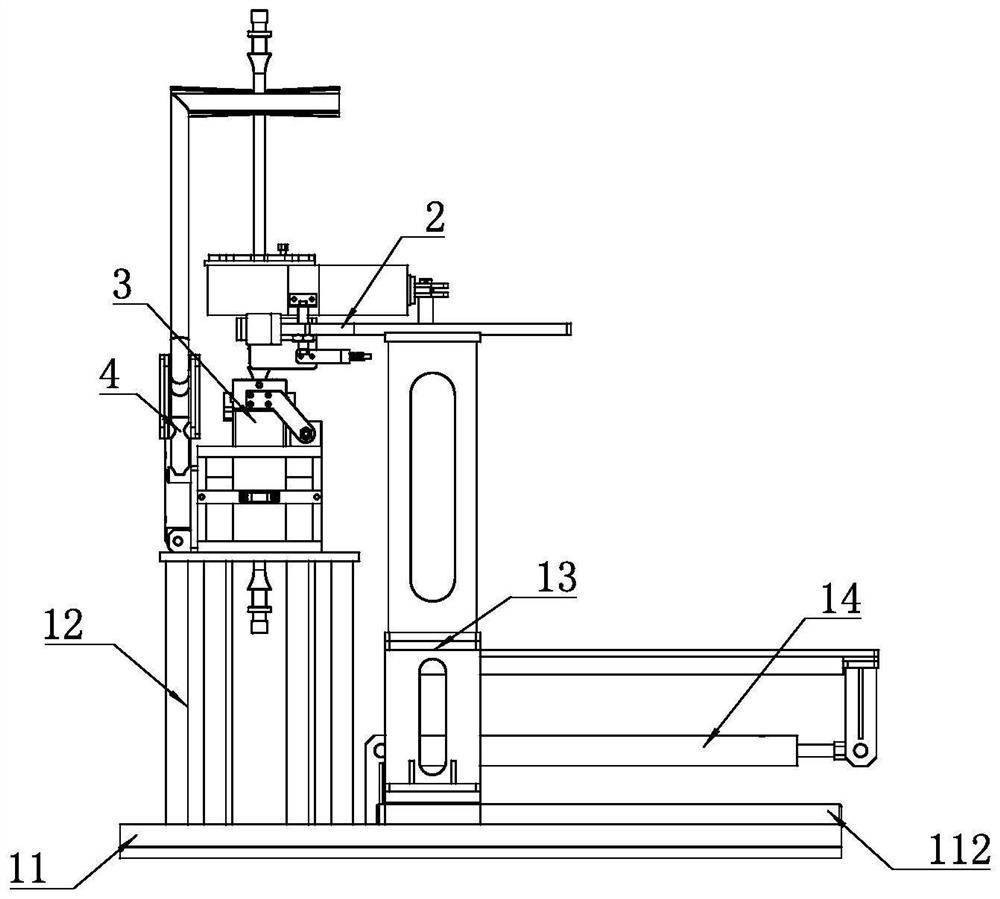

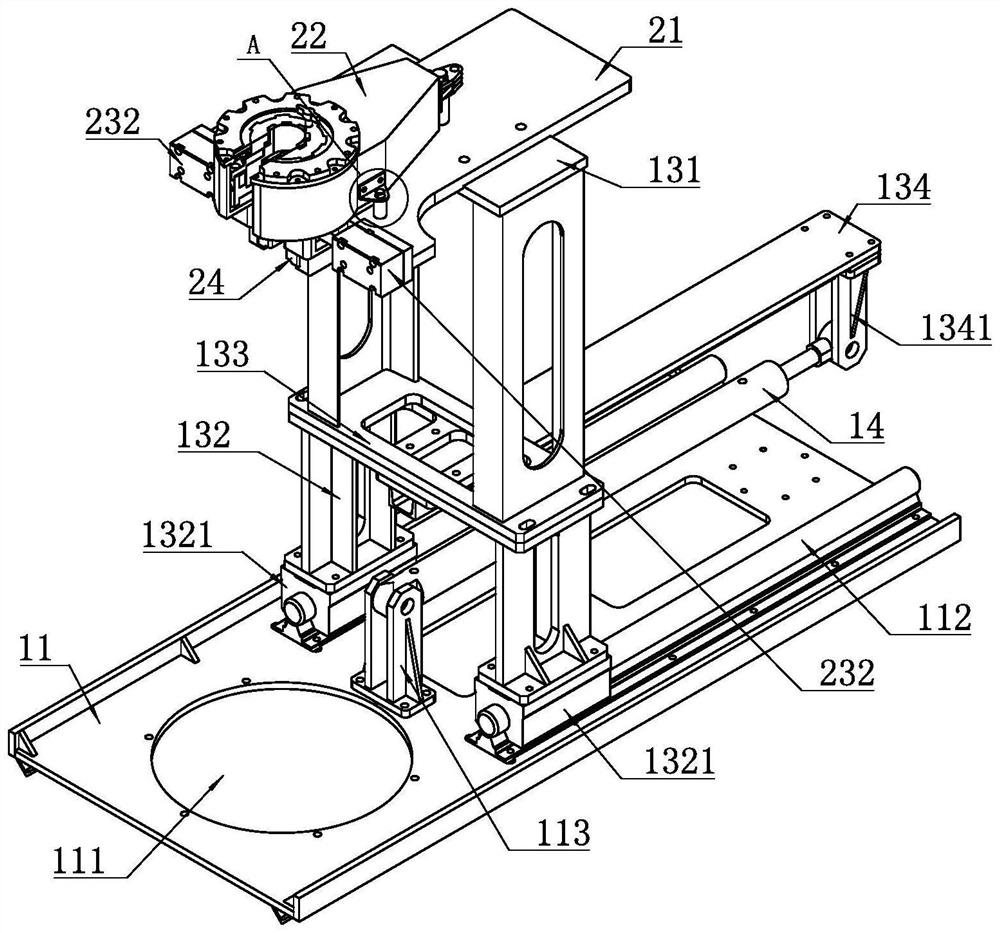

[0050] For the convenience of description, the coordinate system is now defined as figure 1 As shown, the left-right direction is horizontal (row), the front-rear direction is vertical (column), and the up-down direction is vertical.

[0051] like figure 1 and figure 2 As shown, a sucker rod automatic make-up and release device includes a main frame body, and the main frame body is provided with an escape hole for accommodating the sucker rod, and the escape hole vertically penetrates the main frame. The main frame body is provided with a slip mechanism 3 above the avoidance hole, and a power tong 2 that can slide back and forth relative to the main frame body is disposed above the slip mechanism 3 . A driving component 14 for driving the power tong 2 to slide back and forth is arranged between the power tong 2 and the main frame body. The fixed side of the driving component 14 is connected with the main frame body, and the driving component The moving side of 14 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com