Rice dumpling manufacture method and system

A production method and technology of a production system, applied in the field of zongzi production methods and systems, can solve problems such as low efficiency, affecting quality, cumbersome production process of zongzi, etc., and achieve the effect of simplifying production steps and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

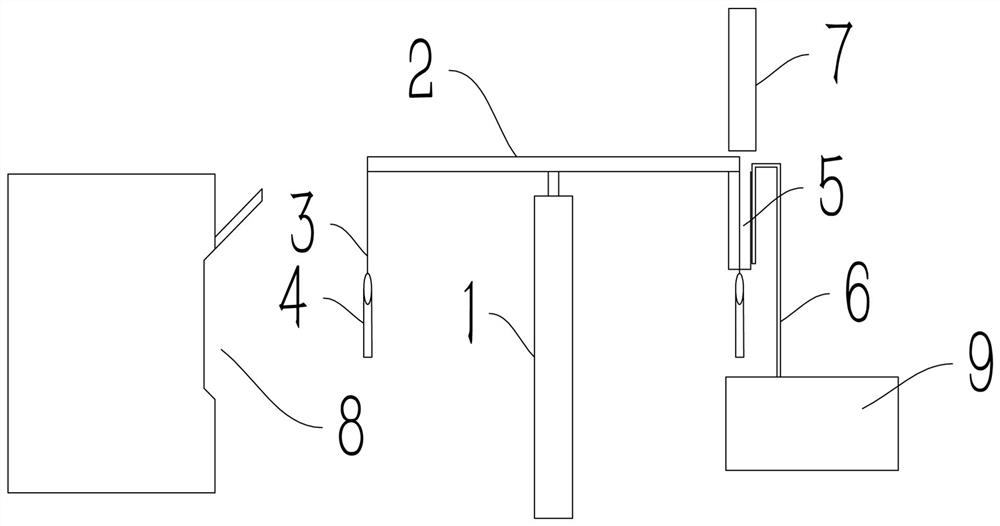

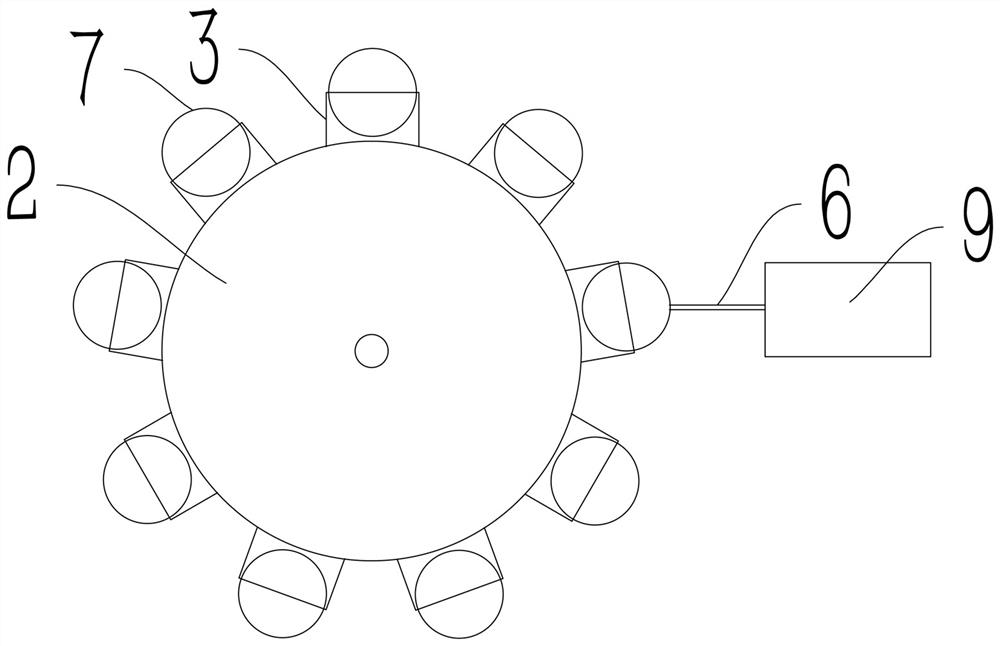

[0030] Embodiment 1: a kind of Zongzi making system, see Figure 1 to Figure 3 , the turntable 2 in the middle, the vacuum chamber 8 on the left, and the filling pump 9 on the right. The turntable 2 is fixed on the rotating shaft 1 and controlled by a stepping motor. The angular displacement of each rotation is fixed, so that along the The clamping mechanisms 3 evenly distributed around the turntable 2 correspond to the vacuum chamber 8 in turn.

[0031] The clamping mechanism 3 pinches both sides of the packaging bag 4, and pulls the front and rear faces of the packaging bag 4 apart by two suction cups to open the opening of the packaging bag. Be positioned at the top of clamping mechanism 3 on the left side and feed channel 7 is set, and it can be provided with cross-section as triangle, square or circle according to the shape of zongzi 10, guarantees zongzi 10 can drop in the packaging bag 4 smoothly. Between the packaging bag 4 and the feed channel 7, a blanking channel 5...

Embodiment 2

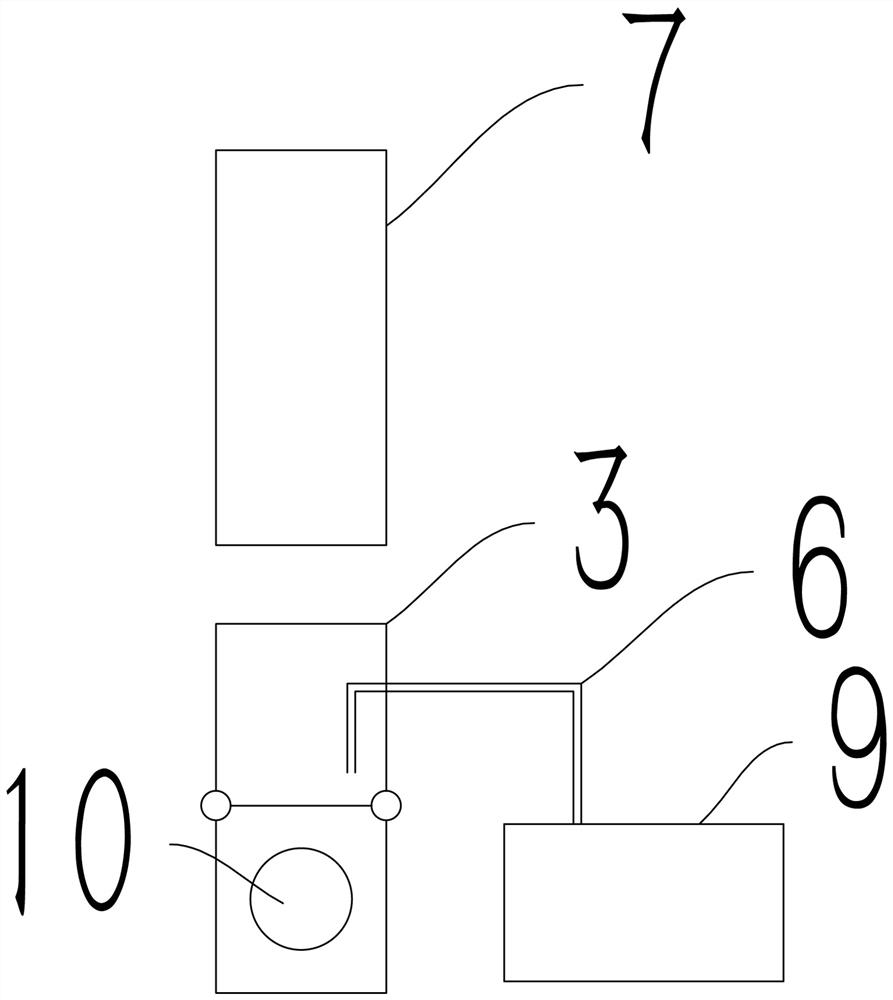

[0034] Embodiment 2: a kind of making method of rice dumpling, utilize above-mentioned system to assist to complete, see Figure 4 , including the following steps:

[0035] (1) Prepare raw materials, including zong leaves, glutinous rice, dressing, seasoning, glutinous rice needs to be washed first and then soaked;

[0036] (2) After the soaking is completed, the zongzi is made by hand, and different shapes can be made according to the needs. At this time, the wrapped zongzi is still a raw zongzi;

[0037] (3) Put the wrapped zongzi into the feeding channel 7 so that it falls into the packaging bag below;

[0038] (4) Turn on the liquid filling pump 9 to inject water or seasoning liquid into the packaging bag. The opening of the liquid filling pump 9 can be automatically controlled according to the time interval set by the rotation speed of the turntable 2. The amount of water added should be moderate to ensure that the rice dumplings can be completely absorbed;

[0039] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com