Through-type traction power supply system

A traction power supply system, through-type technology, applied in the direction of power lines, transportation and packaging, vehicle parts, etc., can solve the problems of frequent movements, short life, lack of processing capacity, etc., to achieve the effect of connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

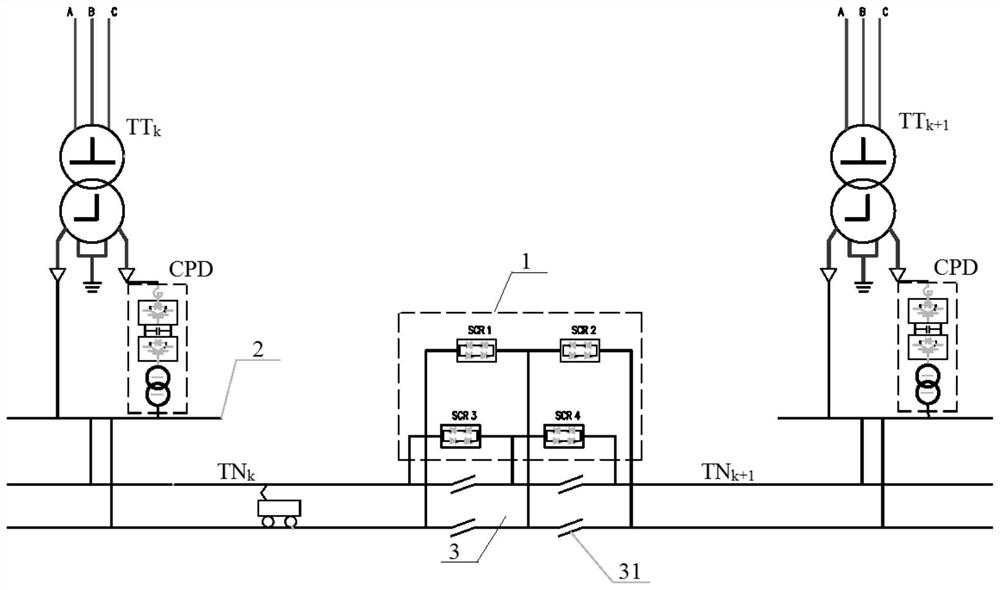

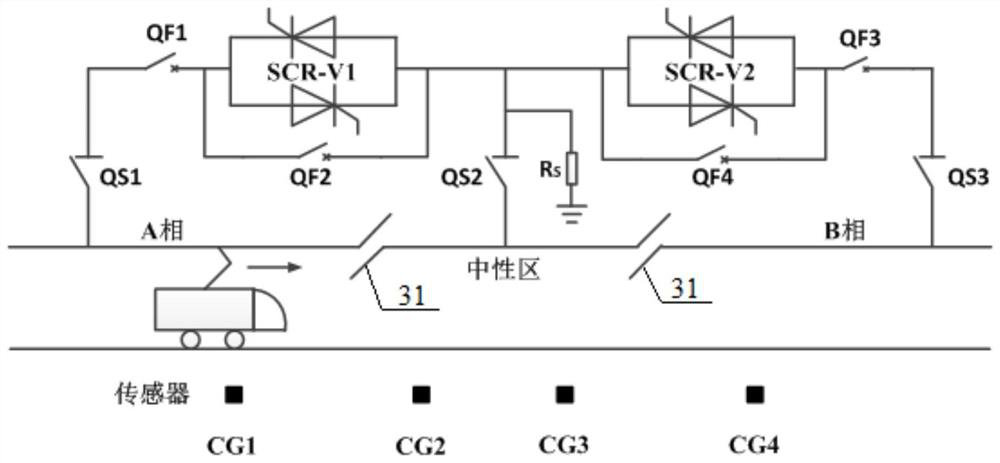

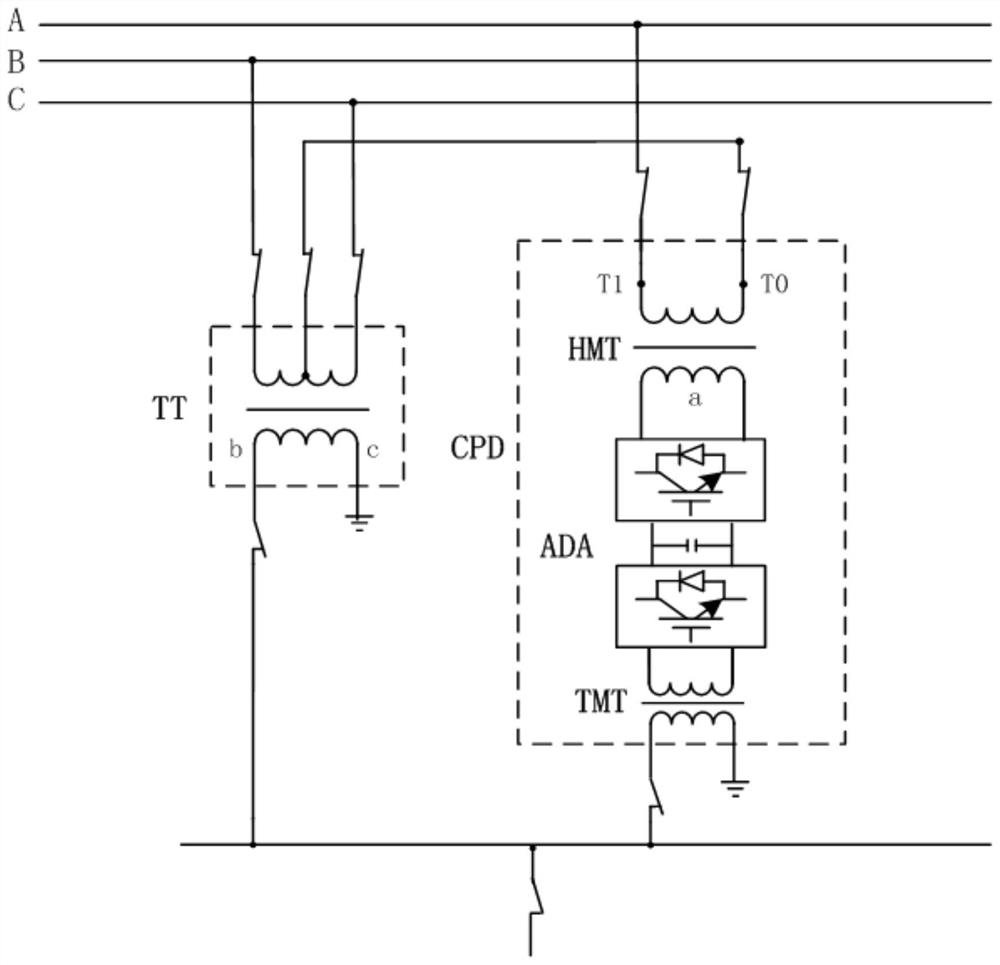

[0032] This embodiment discloses a through-type traction power supply system, such as figure 1 shown, including: the first traction transformer TT k , the second traction transformer TT k+1 , the same phase power supply device CPD, the electronic switch phase splitting device 1, the main substation bus 2 and the partition station 3; the first traction transformer TT k The input end of the system is connected to the three-phase grid, and the first traction transformer TT k The first output terminal of the main substation is connected to the main substation busbar 2, and the first traction transformer TT k The second output terminal of the main substation is connected to the busbar 2 of the main substation through the same-phase power supply device CPD; the second traction transformer TT k+1 The input terminal of the system is connected to the three-phase grid of the system, and the second traction transformer TT k+1 The first output terminal of the main substation is connec...

Embodiment 2

[0055] The through-type traction power supply system provided in this embodiment is suitable for a certain line project in Guangzhou. The total length of the line is about 92.1km, and the design speed is 160km / h.

[0056] Compared with ordinary AC electrified railways, this line has the characteristics of short station spacing, uneven station spacing, and frequent train starting and braking. to the train run. When the train passes through the electric phase separation, the power will be cut off, the traction force will be lost, and the running speed of the train will be affected. If the initial speed of the train is too low, it will cause the train to fail to pass through the electric separation phase by inertia, which will cause a major accident of parking.

[0057] At the same time, each phase separation of the train must be completed through the ground or on-board switch. According to the calculation of one switch operation twice, if 100 pairs of trains are operated every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com