Self-supporting two-dimensional film as well as preparation method and application thereof

A self-supporting and filtering membrane technology, applied in the field of membrane materials, can solve the problems of non-reusable, secondary damage to the self-supporting membrane, and a large amount of toxic and harmful solvents used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In this example, a self-supporting two-dimensional film of MXene was prepared, which was prepared according to the following method:

[0058] (1) At a room temperature of 25°C, uniformly mix nano-alumina and water so that the mass ratio of nano-alumina and water is 1:999, and obtain an aqueous solution of nano-alumina.

[0059] (2) The nano-alumina aqueous solution obtained in step (1) is filtered by a nylon-6 (Nylon 6) base membrane, so that the addition amount of the nano-alumina aqueous solution is 100mL, and the thickness is 100 μm, and the nano-alumina layer is covered. Composite film;

[0060] (3) The composite membrane covered with nano-alumina layer obtained in step (2) was further filtered with 0.05mg / mL MXene two-dimensional material 50mL, dried at room temperature 25°C, and automatically peeled and transferred to obtain a self-supporting two-dimensional membrane .

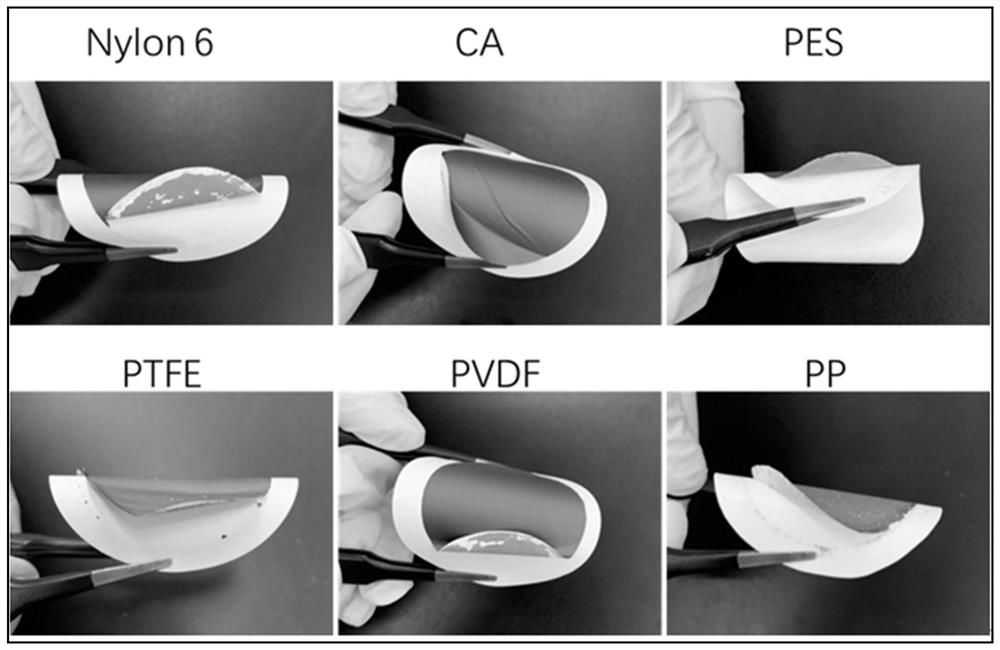

[0061] Automatic peeling transfer process such as figure 2 shown.

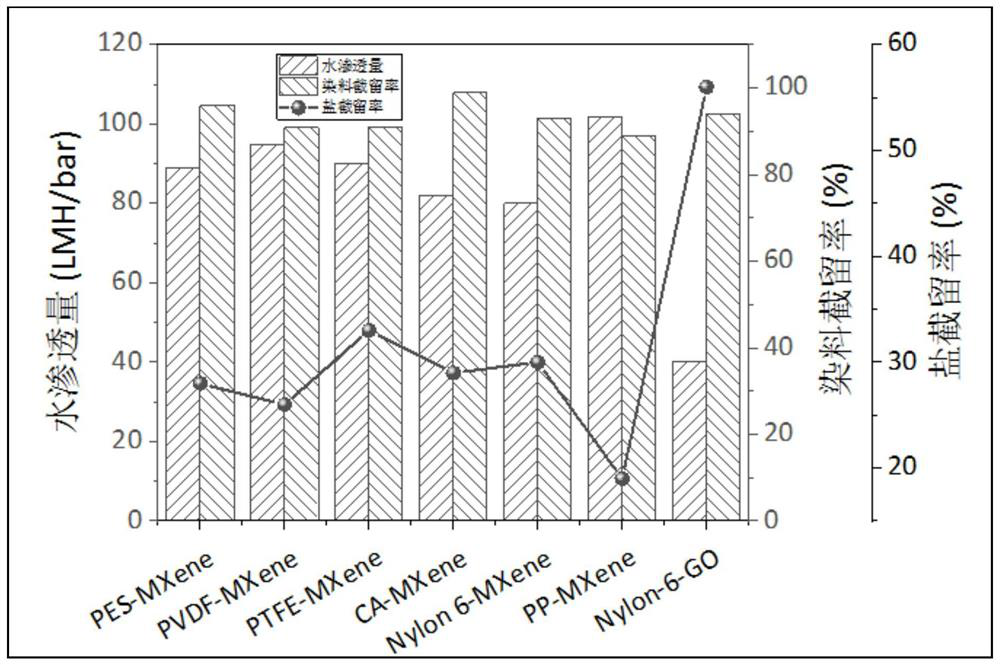

[0062] The MXene self...

Embodiment 2

[0064] In this example, a GO self-supporting two-dimensional membrane was prepared, which was prepared according to the following method:

[0065] (1) At a room temperature of 25°C, uniformly mix nano-alumina and water so that the mass ratio of nano-alumina and water is 1:999, and obtain an aqueous solution of nano-alumina.

[0066] (2) The nano-alumina aqueous solution obtained in step (1) is filtered by a nylon-6 (Nylon 6) base membrane, so that the addition amount of the nano-alumina aqueous solution is 100mL, and the thickness is 100 μm, and the nano-alumina layer is covered. Composite film;

[0067] (3) The composite membrane covered with nano-alumina layer obtained in step (2) was further filtered with 50 mL of 0.05 mg / mL GO two-dimensional material, dried at room temperature at 25 ° C, and automatically peeled and transferred to obtain a self-supporting two-dimensional membrane .

[0068] Automatic peeling transfer process such as figure 2 shown.

[0069] The GO se...

Embodiment 3

[0071] In this example, a self-supporting two-dimensional film of MXene was prepared, which was prepared according to the following method:

[0072] (1) At a room temperature of 25°C, uniformly mix nano-alumina and water so that the mass ratio of nano-alumina and water is 1:999, and obtain an aqueous solution of nano-alumina.

[0073] (2) Filter the nano-alumina aqueous solution obtained in step (1) through a polyethersulfone (PES) base membrane, so that the added amount of the nano-alumina aqueous solution is 100 mL, and the thickness is 100 μm, and a composite composite covering the nano-alumina layer is obtained. membrane;

[0074] (3) The composite membrane covered with nano-alumina layer obtained in step (2) was further filtered with 0.05mg / mL MXene two-dimensional material 50mL, dried at room temperature 25°C, and automatically peeled and transferred to obtain a self-supporting two-dimensional membrane .

[0075] Automatic peeling transfer process such as figure 2 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com