Lithocarpus litseifolius polysaccharide extract with high antioxidant activity and extraction method thereof

A polysaccharide extraction and extraction method technology, applied in the field of plant polysaccharide extraction, can solve the problems of low yield, unsatisfactory antioxidant activity, etc., and achieve the effects of low extraction energy consumption, stable and reliable extraction process, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The extraction of embodiment 1 sweet tea polysaccharide

[0041] (1) Dry the finished sweet tea in a constant temperature hot air oven at 45°C to constant weight, then grind it with a Super Mill-1500 powder machine, then pass through a 60-mesh sieve, put the sweet tea powder into a sealed bag, and store at -20°C spare.

[0042] (2) Accurately weigh 2.0g of sweet tea powder, add it to a 50mL centrifuge tube, and vortex to mix, add 20mL of 80% ethanol (1:10, w / v), use PL-S80T ultrasonic cleaner at 640W power Ultrasound for 30min. After the sample is balanced, it is centrifuged at 4000g for 10 minutes by an X3R high-speed refrigerated centrifuge. After the supernatant is discarded, the precipitate is added to 20 mL of 80% ethanol, and the PL-S80T ultrasonic cleaner is used to sonicate at 80% power for 30 minutes. After the sample is balanced, Centrifuge at 4000 g for 10 min in an X3R high-speed refrigerated centrifuge, and discard the supernatant to retain the precipitat...

Embodiment 2

[0051] The extraction of embodiment 2 sweet tea polysaccharides

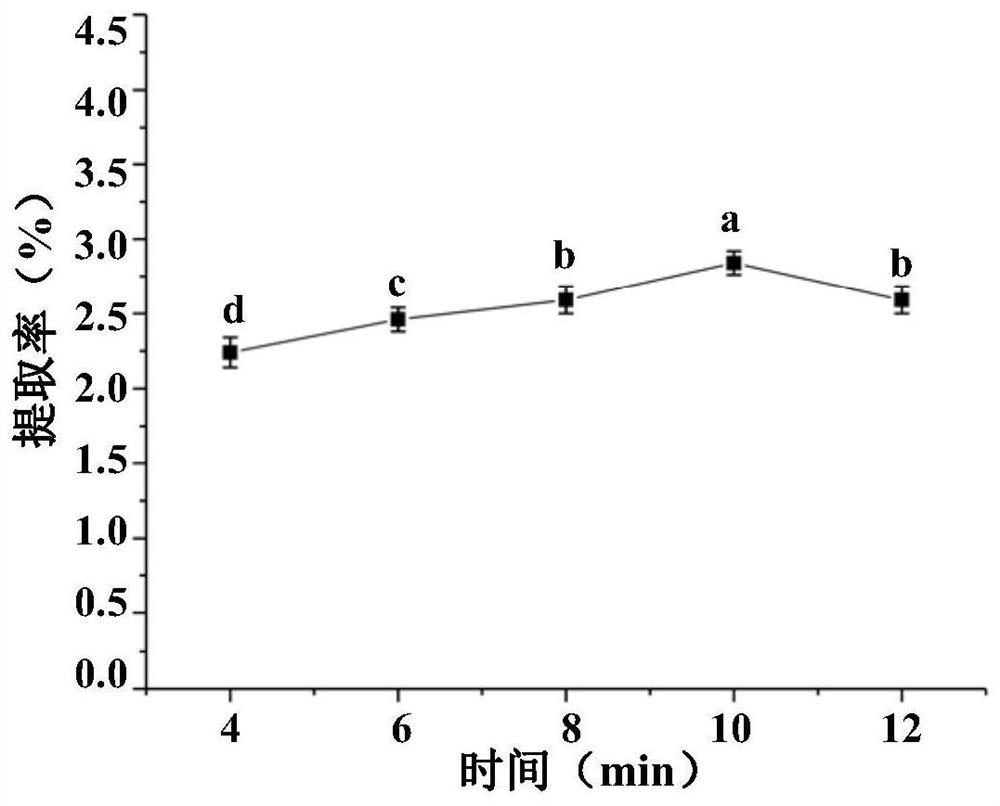

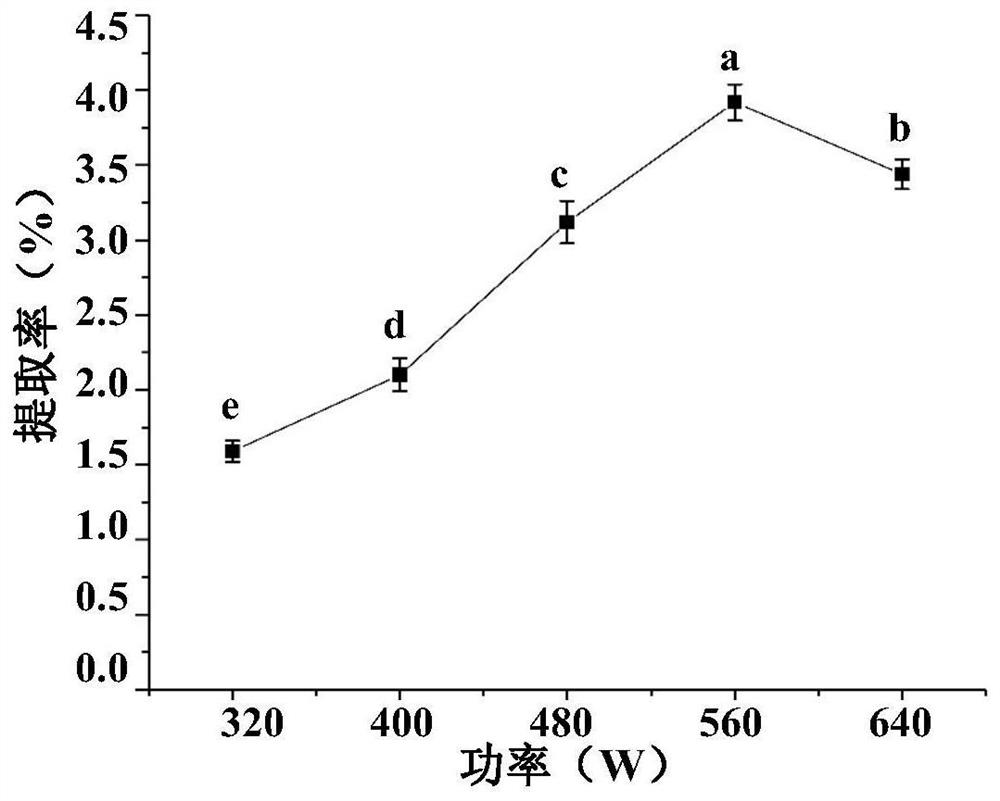

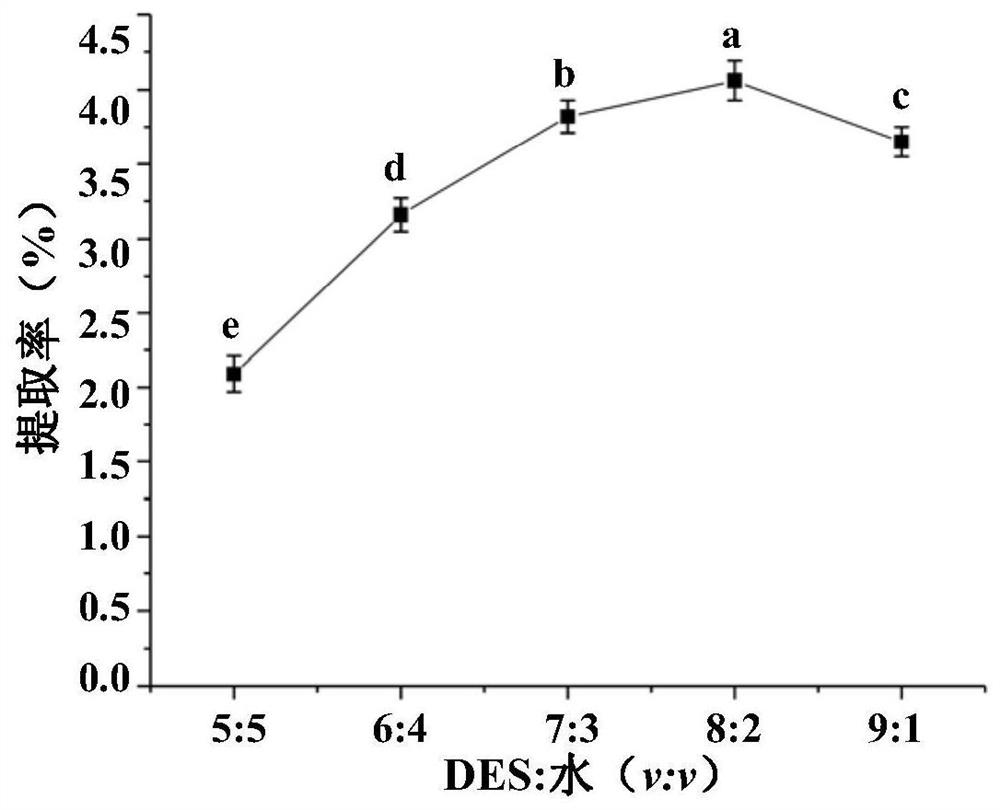

[0052] The difference with Example 1 is that in step (3) choline chloride-ethylene glycol: ultrapure water=8:2 (v:v), the extraction time in step (4) is 10min, and the microwave power is 560W ; All the other are identical with embodiment 1.

[0053] After calculation, the polysaccharide extraction rate of this embodiment is 3.73%, and the polysaccharide extraction yield is 74.6mg.

Embodiment 3

[0054] The extraction of embodiment 3 sweet tea polysaccharides

[0055] The difference from Example 1 is that the extraction time in step (4) is 10min, and the microwave power is 640W; the rest are the same as in Example 1.

[0056] After calculation, the extraction rate of this embodiment is 3.44%, and the extraction yield of polysaccharide is 65.8mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com