Oil and water removal device and particle regeneration manufacturing method based on waste polyester filaments

A manufacturing method and technology of polyester, which is applied in the field of polyester waste recycling and reuse, can solve the problems of limited use and inability to produce long fiber products, and achieve the effects of optimizing the production process, excellent indicators, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of particle regeneration manufacturing method based on polyester waste silk, comprises the following steps:

[0037] Cutting, polyester waste silk is imported into cutting machine, is cut off, obtains the polyester waste silk of 5cm length, and described polyester waste silk adopts the waste silk in the long and short line production process;

[0038] Pelletizing, importing a certain length of polyester waste silk into the fiber agglomerator to obtain irregular pellets;

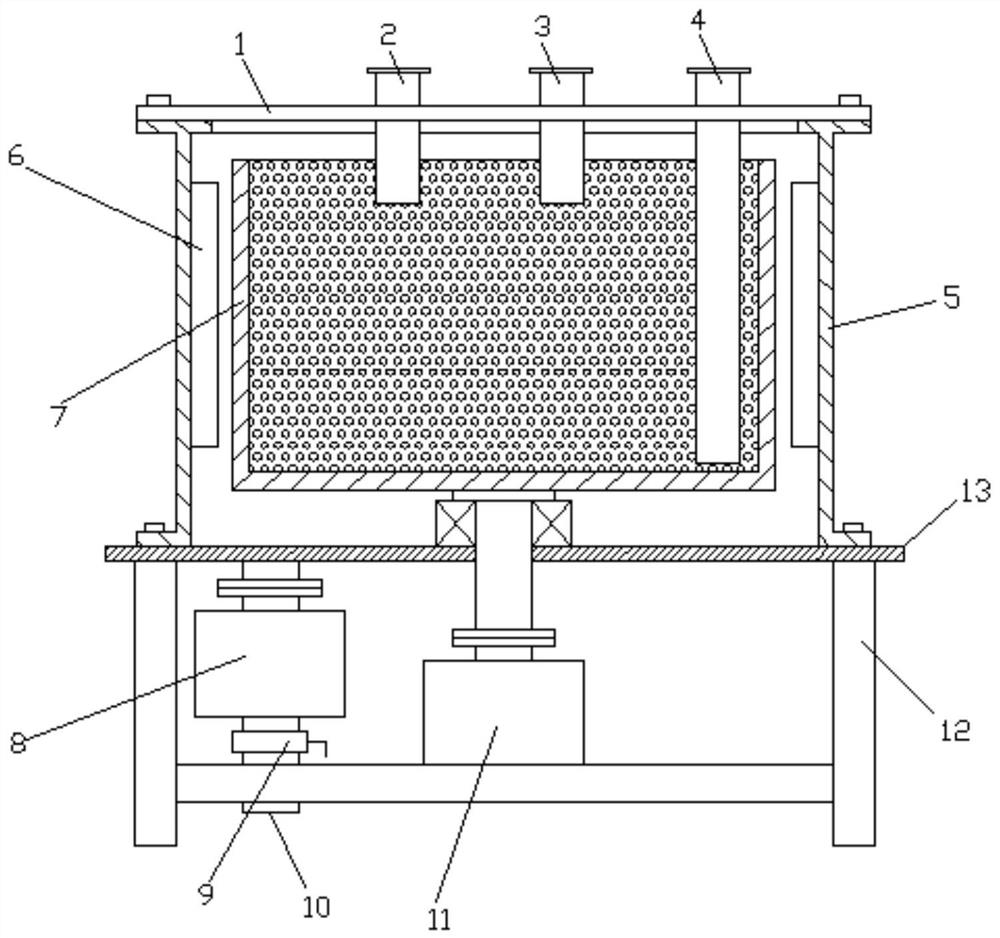

[0039] Oil removal, the pellets are introduced into the oil and water removal device, and the first vacuum devolatilization device is installed on the oil and water removal device to remove the moisture and oil in the pellets in a vacuum environment. The oil and water removal device uses microwave The oil and water removal device is used for stirring and self-heating of the pellets. The temperature in the microwave oil and water removal device is controlled at 225°C to improve the removal effici...

Embodiment 2

[0047] A kind of particle regeneration manufacturing method based on polyester waste silk, comprises the following steps:

[0048] Cutting, the polyester waste silk is imported into the cutting machine, and cut to obtain polyester waste silk with a length of 10cm, and the polyester waste silk adopts the waterside silk in the weaving process;

[0049] Pelletizing, importing a certain length of polyester waste silk into the fiber agglomerator to obtain irregular pellets;

[0050] Oil removal, the pellets are introduced into the oil and water removal device, and the first vacuum devolatilization device is installed on the oil and water removal device to remove the moisture and oil in the pellets in a vacuum environment. The oil and water removal device uses microwave Oil and water removal device, the temperature in the microwave oil and water removal device is controlled at 230°C;

[0051] Extrusion, the pellets are introduced into the screw extruder for melt extrusion, the extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com